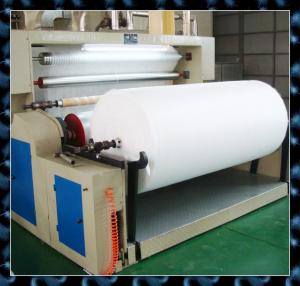

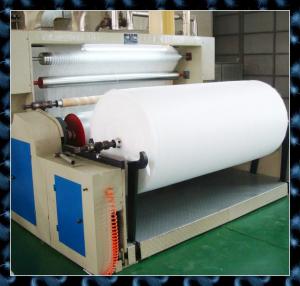

Textile Raw Materials Processing Machinery A

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of Textile Raw Materials Processing Machinery A

| Packaging Detail: | to be packed in seaworthy strong wooden case or carton. |

| Delivery Detail: | about 20days after receipt of the down payment. |

Specifications of Textile Raw Materials Processing Machinery A

It is used for making hollow cotton fiber PP into the fluffy cotton products.Textile Raw Materials Processing Machinery.

output: 100~350kg/h

Power:

Total power; 2.95KW voltage: 380V, 50Hz

Main power : 2.2kWthe power of the conveying fan: 0.75kW

overall size :( L*W*H): 3000×850×1300mm

gross weight: 600kg

Application of Textile Raw Materials Processing Machinery A

It is mainly used for making hollow cotton fiber PP into the fluffy cotton products look like clouds

And applicable to garment, bedding, pillow, and stuff toy, Make products more plumpy & elastic.

It wears conveying fan (user can choose the outlet, it can be padded directly).

- Q:What is velvet?

- Chloe finishing is the use of wool felting to make wool fabric tight and thick hair on the surface of the process, also known as shrink it

- Q:What is the difference between a textile and a woven fabric?

- Warp knitted fabric is the use of a group or several groups of parallel arrangement of yarn, in the feed to the knitting machine on all the work of the needle at the same time into a circle made.

- Q:What is the method of elimination?

- Adjust the release time of the weft, the appropriate adjustment of the folder high and low, left and right position, generally in the right side of the wire length is not greater than 10 ~ 15mm. If shorter than this length, the fabric is easy to produce missing, long waste back to the wire, affecting the yarn specifications.

- Q:What is Uquid's finishing?

- Improve the gloss and take the performance of the process known as liquid ammonia finishing

- Q:How to calculate the density of rapier linen?

- The positive weft insertion method has a strong variety of adaptability, can adapt to all kinds of yarn weft insertion

- Q:What is the rapier?

- The positive weft insertion method has a strong variety of adaptability, can adapt to all kinds of yarn weft insertion

- Q:What is weight loss technology?

- At the same time the yarn in the fiber gap increases, thus forming a true silk style (appearance and feel) of the process, also known as reduction or reduction of alkali

- Q:What is weight gain technology?

- Heavyweight finishing mainly tin plus heavy method and tannin heavier method. The proportion of silk fabric finishing by tin increase, feel thick, smooth, luster and rich, drape increase, shrinkage after moisture reduction B treatment can increase weight 20%

- Q:How does the shuttleless belt adjust the belt?

- 3. With the Allen wrench, unscrew the hexagonal screws on the aluminum arm of the knitting needle, adjust the needle angle, loosen the needle arm fastening screw, move the needle arm up and down, adjust the upper and lower position of the crochet, observe the needle angle and Crochet high and low position, so that the crochet in line with the requirements of the hook

- Q:What is easy to soil (soil - releasing)?

- In particular, synthetic fibers and blended fabrics, easy to take electrostatic adsorption of dirt, and because the surface of poor hydrophilicity, washing water is not easy to penetrate into the fiber gap, dirt is difficult to remove

1. Manufacturer Overview |

|

|---|---|

| Location | Chuji, China |

| Year Established | 2008 |

| Annual Output Value | 100Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 12000 square meters |

| No. of Production Lines | Above5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Textile Raw Materials Processing Machinery A

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 2 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords