Steel Frame Formwork for Light Duty Frame Formwork

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Frame Formwork-Light duty frame formwork

Light duty steel frame of this kind is weighing lightly while bearing high capacity and in some sense it will reduce human cost for customers.

2. Main Features of light duty steel frame formwork

-Simply assemble and disassemble.

-Film faced plywood used to repeat its use with almost 40 times

-Smooth concrete surface to reduce post processing fees.

-Accessories used effectively(such as nail, steel wire, tie rod..).

-Adjustable sizes (1200 steel frame formwork can be adjusted from minimum300mm to maximum 1050mm)

-Easy to move and remove

-Parts used in column steel frame formwork can be used in wall steel frame formwork

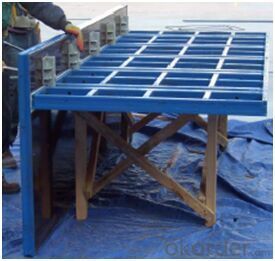

3. Light Duty Steel Frame Formwork Images

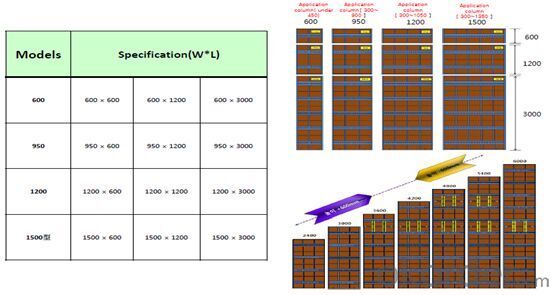

4. Light Duty Steel Frame Formwork Specifications

Column steel frame formwork sizes

5. FAQ of Light Duty Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the Light Duty Steel Frame Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:What are the different types of accessories used with steel frame formwork?

- There are several types of accessories that are commonly used with steel frame formwork systems. These accessories are designed to enhance the efficiency and effectiveness of the formwork, and to provide additional support and stability to the structure being formed. One of the most common types of accessories used with steel frame formwork is the form tie. Form ties are used to hold the formwork panels together and prevent them from spreading apart under the pressure of the concrete. They are typically made of steel and are available in various lengths to accommodate different formwork heights. Another important accessory is the formwork clamp. These clamps are used to securely fasten the formwork panels to the steel frame, ensuring that they remain in place during the pouring and curing of the concrete. Formwork clamps are available in different sizes and designs to accommodate various formwork configurations. Steel formwork also requires strong and durable formwork props or scaffolding to support the weight of the formwork panels and the freshly poured concrete. These props are adjustable in height and provide stability to the formwork system. They are typically made of steel and are available in different sizes and load-bearing capacities. Other accessories used with steel frame formwork include corner connectors, which are used to connect formwork panels at 90-degree angles, and formwork release agents, which help to prevent the concrete from sticking to the formwork surface. Additionally, accessories such as formwork liners can be used to create different surface finishes on the concrete, while chamfer strips can be used to create beveled edges and smooth transitions between different sections of the formwork. Overall, the different types of accessories used with steel frame formwork are designed to provide stability, support, and ease of use, ensuring that the formwork system functions effectively and efficiently during the concrete pouring process.

- Q:Can steel frame formwork be used for both reinforced and non-reinforced concrete?

- Steel frame formwork is capable of being used for both reinforced and non-reinforced concrete. It is a highly adaptable and long-lasting system that can be effortlessly modified and recycled for a range of concrete structures. The steel frames offer robust support and stability, enabling the pouring and molding of both reinforced and non-reinforced concrete. This formwork system is frequently employed in construction endeavors necessitating diverse types of concrete structures, including foundations, walls, columns, and beams. The flexibility and resilience of steel frame formwork render it well-suited for accommodating the distinct demands of reinforced and non-reinforced concrete construction.

- Q:Can steel frame formwork be used in areas with limited crane access?

- Yes, steel frame formwork can be used in areas with limited crane access. Steel frame formwork is a versatile and flexible system that can be adjusted and assembled manually, making it suitable for areas where cranes cannot be easily maneuvered. The steel frames are lightweight and can be easily handled by a small team of workers, allowing for efficient construction even in areas with restricted crane access. Additionally, the modular design of steel frame formwork allows for easy assembly and disassembly, further simplifying the construction process in areas with limited crane access.

- Q:What is the difference between steel frame and steel frame?

- The steel frame belongs to the steel structure, and belongs to the frame structure. According to the framework, the design and construction of steel structure.

- Q:What is the level of precision that can be achieved with steel frame formwork?

- The precision attainable with steel frame formwork is generally high, thanks to its rigid and sturdy structure. This formwork ensures accurate and precise concrete placement by maintaining its shape and dimensions throughout the construction process. By installing and aligning the steel frame formwork properly, precise results can be achieved in terms of wall thickness, flatness, and surface finish. The tight joints and connections of the steel frames minimize the potential for concrete leakage or seepage, resulting in a consistent and uniform appearance. Furthermore, steel frame formwork offers flexibility for easy adjustments and modifications, allowing for precise alterations in dimensions and shapes according to construction requirements. This adaptability guarantees the desired level of precision in the final product. Nevertheless, it is important to consider that achieving a high level of precision also relies on factors such as the quality of the steel frame formwork, the expertise of the construction crew, and proper supervision and quality control measures.

- Q:What are the different types of formwork clamps used with steel frame formwork?

- There are several different types of formwork clamps that are commonly used with steel frame formwork. These clamps are designed to securely hold the formwork panels in place and ensure that they do not shift or move during the concrete pouring process. One type of formwork clamp that is often used with steel frame formwork is the wedge clamp. This type of clamp consists of a metal wedge that is inserted into a slot on the formwork panel and then tightened to secure the panel in place. The wedge clamp is easy to use and can be quickly adjusted or removed as needed. Another type of formwork clamp that is commonly used with steel frame formwork is the hook clamp. This type of clamp consists of a metal hook that is inserted into a hole on the formwork panel and then tightened to secure the panel in place. The hook clamp provides a strong and secure connection between the formwork panel and the steel frame. In addition to wedge and hook clamps, there are also other types of clamps that can be used with steel frame formwork. These include spring clamps, which use a spring mechanism to hold the formwork panels in place, and toggle clamps, which use a lever mechanism to securely fasten the panels. These clamps can be easily adjusted and provide a strong and reliable connection between the formwork panels and the steel frame. Overall, the different types of formwork clamps used with steel frame formwork provide a variety of options for securely holding the formwork panels in place. Each type of clamp has its own advantages and disadvantages, and the choice of clamp will depend on the specific requirements of the construction project.

- Q:Can steel frame formwork be used for the construction of parking structures?

- Certainly, parking structures can be constructed using steel frame formwork. This system is known for its versatility and durability, as it provides essential support and structure throughout the construction process. It boasts the ability to handle heavy loads and withstand the pressures and stresses associated with parking structures, making it an advantageous choice. Furthermore, steel frame formwork allows for effortless and efficient assembly and disassembly, making it a practical option for projects that demand speed and flexibility. By employing steel frame formwork in the construction of parking structures, a robust and trustworthy end product can be achieved, meeting all necessary safety standards.

- Q:How does steel frame formwork contribute to the overall speed of construction?

- The overall speed of construction is enhanced by steel frame formwork in several ways. To begin with, this type of formwork is designed to be reusable, allowing it to be used for numerous construction projects. This not only saves time but also reduces the cost of procuring formwork. As a result, there is no longer a need for traditional timber formwork, which typically requires construction and dismantling for each project. Moreover, steel frame formwork is easy to handle and lightweight, enabling quick and efficient installation. As a result, workers can easily move and position the formwork panels without the use of heavy machinery or excessive manpower. This expedites the construction process significantly. In addition, steel frame formwork is extremely versatile and can be adjusted to fit various shapes and sizes. This adaptability allows for different architectural designs to be accommodated, thereby streamlining the construction process. By using the same formwork system for different parts of the project, there is no longer a need for custom-made formwork for each specific component. Furthermore, steel frame formwork offers exceptional stability and strength, guaranteeing the accuracy and quality of the concrete structures. Consequently, there is no longer a need for excessive remedial work or repairs, saving time and resources that would otherwise be spent on rectifying errors. In conclusion, steel frame formwork contributes to the overall speed of construction through its reusability, lightweight nature, versatility, and provision of stability. These factors enable faster and more efficient construction, resulting in reduced project timelines and enhanced productivity.

- Q:How long does steel frame formwork typically last?

- Steel frame formwork typically lasts for several years, with proper maintenance and care. The exact lifespan can vary depending on factors such as usage, environmental conditions, and quality of materials.

- Q:Can steel frame formwork be used in projects with limited construction site supervision or management?

- Steel frame formwork is a versatile and durable solution for creating concrete structures, making it suitable for projects with limited construction site supervision or management. Its robustness allows it to withstand heavy loads and extreme weather conditions, ensuring stability even without constant supervision. Moreover, the ease of assembly and disassembly of steel frame formwork facilitates quick installation and removal, reducing the need for skilled labor and speeding up the construction process. Additionally, its adjustability and customization capabilities enable construction teams to modify the formwork system without extensive supervision or guidance. Furthermore, the high reusability of steel frame formwork minimizes the need for constant supervision or management in terms of material procurement. This means that even with limited supervision on-site, the formwork system can be reused multiple times. However, it is important to note that proper installation and usage of steel frame formwork still require some level of expertise and knowledge. Therefore, it is advisable to have at least some level of supervision or management to ensure correct implementation. In conclusion, steel frame formwork is a suitable option for projects with limited construction site supervision or management. Its durability, ease of assembly, flexibility, and reusability make it a reliable choice. However, it is crucial to ensure that there is still some level of expertise or guidance to ensure proper installation and usage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Frame Formwork for Light Duty Frame Formwork

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords