Steel Billet Made in China/ China Manufacture/GB ASTM DIN

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Square steel billet

1.Chemical Analysis | |||

Grade | Carbon(%) | Manganese(%) | Silicon(%) |

A | 0.14~0.22 | 0.30~0.65 | Max0.30 |

B | 0.12~0.20 | 0.37~0.67 | Max0.30 |

C | Max0.18 | 0.35~0.80 | Max0.30 |

D | Max0.17 | 0.35~0.80 | Max0.35 |

2.Mechnical Properties | |||

Tensile Strength(σb/Mpa) | Elongation(δ5/%) | ||

375---500 | ≥26(a≤16mm) | ||

3.basic information | |||

length | Spectfication(mm) | Material quality | Executive standard |

6m | 120*120 | Q235 | GB700-88 |

4.Trade information | |||

Price terms | Payment terms | Delivery time | Packing |

FOB/ CIF | T/T, L/C | Within 30 days | bundles |

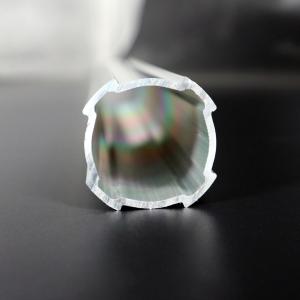

Product Picture

FAQ

Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

Q: What's the MOQ?

A: Our MOQ is 1000mt.

Q: What's the delivery time?

A: It will take about 40 days after TT or L/C.

Q: What is the payment terms?

A: T/T, L/C at sight

Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q:How can steel products be recycled and reused?

- Steel products can be recycled and reused through a process called steel recycling. This involves collecting scrap steel from various sources, such as old cars, appliances, and construction materials, and melting it down in a furnace. The molten steel is then cast into new products, such as steel bars, beams, and sheets. This recycling process not only conserves natural resources but also reduces energy consumption and greenhouse gas emissions. Additionally, steel can be reused by refurbishing and repurposing existing steel products, such as furniture, machinery, and infrastructure, extending their lifespan and minimizing waste. Overall, steel recycling and reusing play a crucial role in promoting sustainability and circular economy practices.

- Q:How is steel forgings heat-treated for improved mechanical properties?

- Steel forgings are heat-treated through a process called quenching and tempering to enhance their mechanical properties. Initially, the steel is heated to a high temperature and then rapidly cooled, or quenched, in a liquid medium such as oil or water. This rapid cooling helps to achieve high hardness and strength in the material. Following quenching, the steel is tempered by reheating it to a lower temperature to relieve internal stresses and improve toughness while maintaining a desirable level of hardness. This heat treatment process is crucial in optimizing the mechanical properties of steel forgings, making them more durable and suitable for various applications.

- Q:How is steel used in the energy sector?

- Steel is used in the energy sector in various ways, primarily for infrastructure and equipment. It is used to construct power plants, transmission towers, and pipelines, providing the necessary structural strength and durability. Additionally, steel is used in the production of turbines, generators, and transformers, which are crucial components in the generation and distribution of electricity.

- Q:How are steel profiles used in the fabrication of storage racks?

- Steel profiles are commonly used in the fabrication of storage racks due to their strength and durability. These profiles serve as the main structural components, forming the framework for the racks. They are cut, shaped, and welded together to create sturdy shelves and supports, ensuring the racks can withstand the weight of various items being stored. Additionally, steel profiles can be easily customized to accommodate different storage needs, such as adjustable shelving or specialized racks for specific products.

- Q:What are the different types of steel brackets and connectors available?

- There are various types of steel brackets and connectors available, including corner brackets, angle brackets, T-shaped brackets, L-shaped brackets, straight connectors, and adjustable connectors. These brackets and connectors are designed to provide structural support and reinforcement in various construction and woodworking applications.

- Q:How are steel products used in the construction of museums and cultural centers?

- Steel products are commonly used in the construction of museums and cultural centers for their strength and durability. They are used in various structural components such as beams, columns, and trusses, providing stability and support for the building. Steel is also used for roofing, cladding, and façade systems, offering both aesthetic appeal and weather protection. Additionally, steel is often used in the construction of exhibit displays and installations, providing a flexible and customizable solution. Overall, steel products play a crucial role in creating safe, long-lasting, and visually appealing spaces for preserving and showcasing cultural artifacts and experiences.

- Q:What is the process of steel galvanization?

- The process of steel galvanization involves coating steel with a protective layer of zinc. This can be done through either hot-dip galvanization or electro galvanization. In hot-dip galvanization, the steel is immersed in a bath of molten zinc, which forms a metallurgical bond with the surface of the steel. Electro galvanization, on the other hand, uses an electric current to deposit a layer of zinc onto the steel surface. Both methods provide a corrosion-resistant coating, extending the lifespan of the steel and protecting it from rust and other environmental damage.

- Q:How is steel sheet metal fabricated?

- Steel sheet metal is fabricated through a process called sheet metal fabrication, which involves cutting, bending, and shaping steel sheets to create various products or components. This can be done using various techniques such as shearing, punching, laser cutting, or plasma cutting to cut the steel sheets into the desired shape. Bending is then carried out using press brakes or other bending tools to give the sheets the required angles and curves. The final step involves assembling or joining the fabricated pieces using welding, riveting, or other joining methods to create the desired steel sheet metal product.

- Q:How is steel used in the production of playground equipment?

- Steel is commonly used in the production of playground equipment due to its strength, durability, and ability to withstand harsh outdoor conditions. It is used to construct frames, supports, and other structural components of swings, slides, climbing structures, and various playsets. The use of steel ensures the safety and longevity of playground equipment, making it a vital material in their production.

- Q:What are the different types of steel coatings and their applications?

- There are several types of steel coatings available, each with its own unique properties and applications. Some common types include galvanized coatings, which provide corrosion resistance and are often used in outdoor applications; powder coatings, which offer durability and a decorative finish and are commonly used in consumer goods and automotive industries; epoxy coatings, which provide protection against chemicals and abrasion and are often used in industrial settings; and thermal spray coatings, which offer high temperature resistance and are commonly used in aerospace and power generation industries. These are just a few examples, and the choice of coating depends on the specific requirements of the application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Billet Made in China/ China Manufacture/GB ASTM DIN

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords