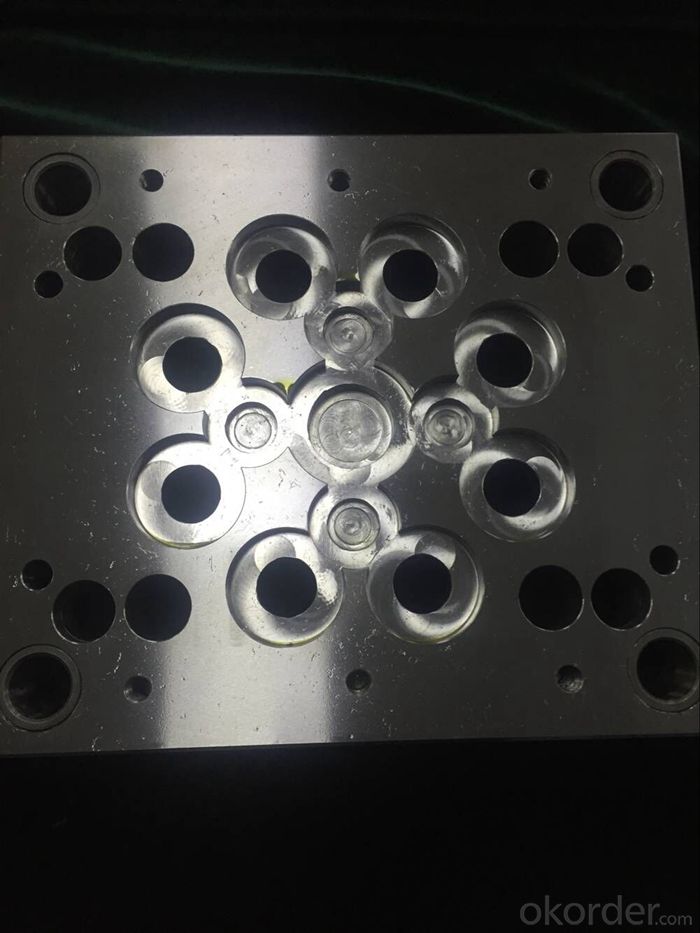

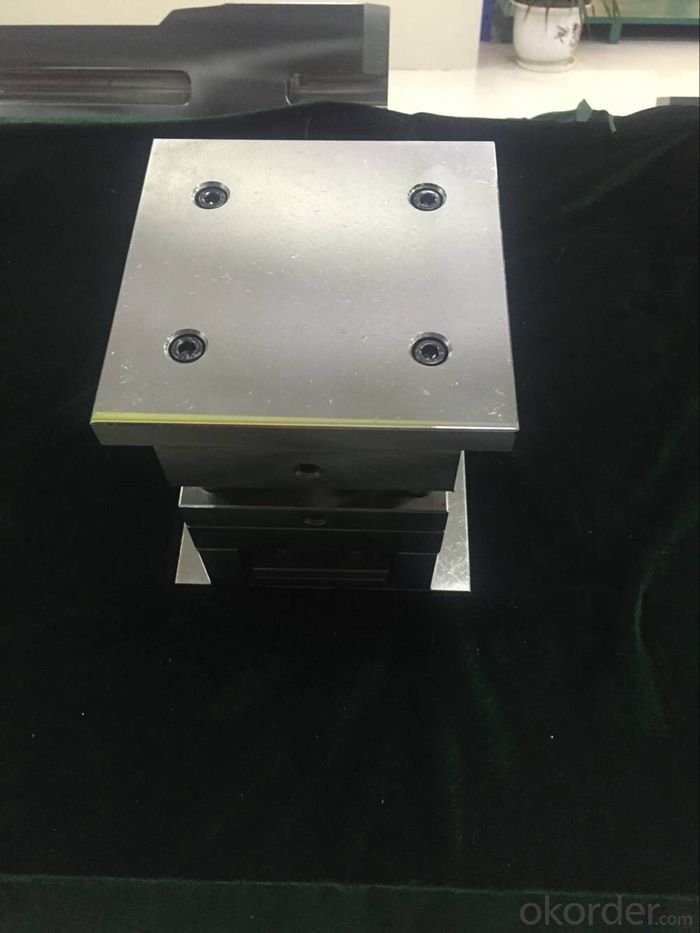

Stamping Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Our company specializes in manufacturing all kinds of plastic standard and non-standard mold, die-casting mould, stamping mould and all kinds of Euro HASCO mould frame.

The accessories are all made of standard guide pillar & bushes.

Thickness tolerance are processed according to requirements of 0.00 to 0.02.

High surface finish and roughness of standard.

Various types of formwork could be processed according to figure.

- Q:The performance requirement of die steel

- Red hardness Work under high temperature condition of hot-work die to maintain the stability of the organization and performance, to maintain a high enough hardness, this performance is called red hardness. Carbon tool steel, low alloy tool steel can often in 180 ~ 250 ℃ temperature range of this kind of performance, chrome molybdenum steel is in commonly 550 ~ 600 ℃ temperature range this performance. The red hardness of steel mainly depends on the chemical composition of the steel and the process of heat treatment.

- Q:Introduction to mould design and manufacturing

- Having the necessary natural science, social science and management scientific knowledge; Knowledge of computer knowledge, necessary network knowledge, common software knowledge; Basic knowledge of mechanical knowledge; The basic knowledge of mechanical design theory, mould material and forming process, mould design and manufacturing expertise of this major. Knowledge of mould CAD/CAM. Basic knowledge of mould maintenance is necessary. Have certain self-study ability; Have the tooling design, process implementation, technical management capability; Have the ability of machining and programming of mould control; With injection mould, stamping mould design and manufacturing capacity; It has the ability of the working ability of the fitter, the mould repair ability; Good computer base application and computer aided design manufacturing and management capability; Ability to design and process mould design with CAD/CAM software. Good verbal, verbal and interpersonal skills.

- Q:What is a mold bite

- The molds of molds are treated with the surface corrosion reaction of the steel surface, such as concentrated sulphuric acid, forming the skin/erosion/pear ground or other forms of grain.

- Q:What is a molds? What is the difference between die and die?

- The difference is that the mold is a tool for molding objects. If you're going to do a bunch of things that look almost exactly the same, you need molds. The personal seal, for example, is the simplest mold. A mold is a production tool. A treatment is a work suit, a supporting tool designed to achieve a certain purpose. For example, in order to spin a screw, we invented a screwdriver, and the screwdriver is a work suit. Tooling is not a production tool.

- Q:The processing method of the mold cavity processing center

- The common processing procedure of the cavity: (milling) around and on both sides, the thickness remains 0.4 minus 0.6rnrn. Two sides of the face and two sides of adjacent side, the surface roughness Ra is 0.8 mu m. The shape of the fitter and the position line of the screw hole. The pattern required the milling out of the cavity, the unilateral remaining balance of 0.3 one-half mm, The machine drill screw holes, thread and so on. 6. Heat treatment. The electrode is used in a rough machining cavity. The worker finishes the polishing. The design calls for chrome plating, etc. The equipment was repaired and inspected.

- Q:Why does the mold exhaust, so where does the gas come from

- There are several main sources of the gas in injection molding mold: the air in the cavity and the pouring system; The water vapor produced by the evaporation of water from the plastic material. Gases produced by plastic decomposition at high temperature; Gases produced by certain additives in plastics or chemical reactions, such as thermosetting plastics, are often produced by chemical reactions.

- Q:What is suitable for moulding steel

- Plastic moulds include thermoplastic moulds and thermosetting plastic moulds. The plastic mould requires certain strength, hardness, abrasion resistance, thermal stability and corrosion resistance. In addition, it also requires good manufacturability, such as heat treatment deformation is small, processing performance, corrosion resistance, good repair welding, grinding and polishing performance is good, good performance, high roughness, good thermal conductivity and working conditions have stable size and shape, etc. In general, the injection molding or extrusion die can be used for the heat making die steel. Hot solidification and the requirement of high wear-resisting and high strength mold can be used in cold making die steel.

- Q:Is the stainless steel bowl replaceable in the oven?

- I had been sitting in a stainless steel basin for several times, and now I wonder why I spent so much money on the molds, which was much cheaper, a ten-inch dish of ten dollars.

- Q:How long is the life of die casting die?

- Aluminum: 120000 times Copper: 20000 times Magnesium: 200000 times Zinc: 500000 times Benchmark, the product structure added and reduced die life

- Q:What is die parting face?

- For example: a plastic ball, it is of two quasi semicircle, looked closely, can see a circle line is the parting surface, if it is a big a small half sphere of clamping, can't do that most of the ball out from the mold. So the parting face should be easy to make, easy to make, low cost of making, and some of the addition of insert and exit.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stamping Mould Mould Base for Plastic Injection Moulding

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords