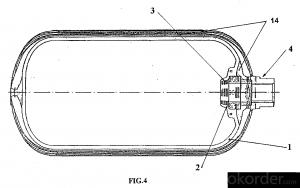

single screw plastic extruder for PE PP film granulating line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

SINGLE SCREW PLASTIC EXTRUDER IS WIDELY USED ON EXTRUSIONG PLASTIC PIPE,PLASTIC PROFILE,PLASTIC SHEET/FILM,PLASTIC BOARD/PLATE.

Applications of single screw plastic extruder for PE/PP film granulating line :

SINGLE SCREW PLASTIC EXTRUDER IS WIDELY USED ON EXTRUSIONG PLASTIC PIPE,PLASTIC PROFILE,PLASTIC SHEET/FILM,PLASTIC BOARD/PLATE,AND ALSO IT CAN BE USED ON PLASTIC GRANULATION.

MODELS OF single screw plastic extruder for PE/PP film granulating line :

- Q:Is environmental protection approved for plastic granulation?

- According to the provisions of the "construction project environmental impact assessment classification management directory", plastic products manufacturing in artificial leather, foam rubber involving toxic materials; a plating process requires the preparation of the EIA report; the rest of the need for the preparation of the EIA report table.

- Q:How about the granulator?

- Our company absorb domestic and foreign advanced technology and experience, in strict accordance with the national requirements of GMP design, development, production, installation and service in one, and in strict accordance with the ISO9001 international quality system standards implementation, to ensure product quality.

- Q:How to solve the noise of plastic granulator

- Change the mute hob cutter or water ring pelletizer.

- Q:May I ask who knows the plastic granulator manufacturers contact ~ figure

- China is the same, who knows who ah?. Otherwise, better contact

- Q:How is the feeding instability of the single screw plastic granulator?

- It depends on what kind of machine you are. What kind of material will be used and the temperature at the inlet should not be too high. Is it a regular granulator?.

- Q:The difference between the whole machine, granulating machine, granulating machine of the three English translation?

- Features: complete machine without dead angle, residual, concave convex surface and screw, easy to clean. ? highly polished inside and outside surfaces. The inner surface roughness Ra is less than or equal to 02 m, and the surface roughness Ra is less than or equal to 0.4 mu m. ? equipped with casters door type high support, and NTF series lifting machine and LD series mixing hopper supporting the use of, optimize the process flow. ? all parts can be disassembled and cleaned conveniently

- Q:What plastic particles are used for wire injection? How much would you like to invest in a plastic pelleting plant?

- Look at the product use and performance parameters, it is necessary to add some,

- Q:What's the fabric of the plastic bread machine?! What's in the cloth?

- The plastic granulator is made of glass fiber cloth, which plays an insulating role. Inside the cloth is an electric heating wire used to heat the barrel and melt the plastic.

- Q:How much will it cost to invest in the recycled plastic particle production line?

- Depends on the output, from about 60 thousand to millions of start.

- Q:How to calculate the plastic granulator gear ratio, to control the length of the particle

- Main parameters: diameter of traction roller. Cutter diameter and cutter tooth number. Back gear ratio. Let's put these parameters together. I dare not speak too much

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

single screw plastic extruder for PE PP film granulating line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches