RUBBER VULCANIZING ACCELERATOR·DPG (D)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 120000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chemical Name: Diphenyl guanidine

Molecular Formula: C13H13N3

Molecular Weight:211.27

CAS NO.: 102-06-7

Executive standard:Q/CNPC55-2001

Specification

|

Item |

Index | |

|

First-class products |

Acceptable end-product | |

|

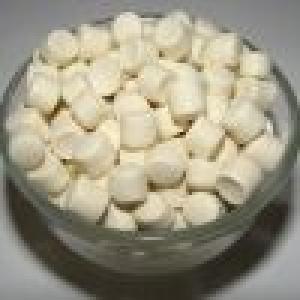

Appearance(Visual inspection) |

white powder |

Greyish-white powder |

|

Initial M.P, oC ≥ |

145.0 |

144.0 |

|

Loss on drying, % ≤ |

0.20 |

0.30 |

|

Ash, % ≤ |

0.30 |

0.40 |

|

Residues on 150μm sieve,% ≤ |

0.10 |

0.10 |

|

Residues on 63μm,% ≤ |

0.50 |

0.50 |

Properties: Grayish-white or white powder notaste, nontoxic . Density is 1.13--1.19. Soluble in acetone, ethyl acetate, benzene, alcohol, slightly soluble in carbon tetrachloride Insoluble in water and gasoline.

Application: mainly used for natural rubber syntheic the medium-speed accelerator. Used in thiazoles, Autumn Lamb, and the second category of iodine acid catalyst for the active agent, and agent for DM, TMTD used, can be used for continuous vulcanization. Mainly used in the manufacture of tires, plastic sheet, soles and industrial products, rigid and thick plastic products.

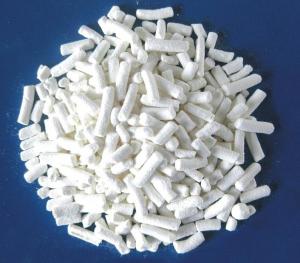

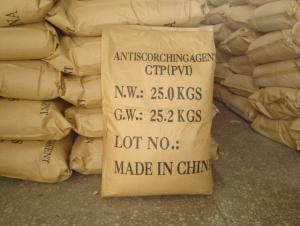

Packaging: Polypropylene knitted bags lined with polyethylene bags.Net weight 25kg per bag.

Storage: Keep container tightly closed in a cool, well-ventilated place. The recommended maximum storage life is 2 years when stored under normal conditions.

Note: The product could be oiled and pelleted apon customer request.

- Q:What is the silane impregnant

- Silane impregnant is a high performance silane product for the anticorrosive effect of reinforced concrete structures on concrete surfaces such as isobutyltriethoxysilane DB-H538, isooctyltriethoxysilane DB-H580, etc. ( China Daoer chemical industry can provide professional). Are relatively stable small molecular structure, painted to the concrete ...

- Q:What is the color of the isobutyl silane impregnant for concrete anticorrosion?

- Should be substandard products, ask for inspection reports, manufacturers qualified to prove, or return.

- Q:How to determine the load when the load is loaded

- The amount of active components and additives is an important factor affecting the catalytic performance of the catalyst, the active components, the amount is too small, the activity of course, with the increase in the amount of load, the activity slowly increased, but generally have An optimum value, greater than the optimal value of the time, the activity is basically the same, even due to the load is too large caused by metal sintering,

- Q:The laboratory was used as a rotary sprinkler for impregnation of the catalyst

- Laboratory to buy a dip is pulling method of coating with a CNC pull device, you can set many parameters, rising and lowering speed, coating height, immersion time, the number of coating and so on. Which rise and fall speed can reach 1um / s,

- Q:Friends, ask you a question, the capacitor of the different impregnation, capacitance What is the difference?

- The impregnant determines the dielectric coefficient of the capacitor medium, which determines the capacitance and field strength of the capacitor.

- Q:How to do the best volume impregnation to prepare a supported catalyst?

- A certain amount of material by adding excess water, immersed for a period of time after the filter, calculated by the amount of material to be adsorbed by the amount of water, so as to get the saturated adsorption capacity of the material bolted (station contact TA) recommended the use of insects have resources bingyu0729 ( Station contact TA) take a certain amount of material to measure its saturated adsorption volume, then this part is in the back of the impregnation of the precursor solution, it can not be used to be lost? The amount of catalyst to do is not much zhangwengui330 (station contact TA) and other volume impregnation is not the most homogeneous preparation method, in order to achieve uniform control, often take the method of adding additives such as microemulsion

- Q:The use of silane impregnants

- Silane impregnant, the product is suitable for seawater corrosion, salt spray, snow melting agent corrosion and freeze-thaw damage to the protection of concrete structure, for the harbor pier, sea bridge, cross river bridge, water conservancy project dam, urban viaduct, high-grade highway bridge , Railway bridges, tunnels, airport pavement, water concrete construction, thermal power, nuclear power plants, sewage treatment plants and other anti-corrosion.

- Q:Dipping method and precipitation method to prepare the catalyst

- The non-roasting catalyst is easily lost with the solution

- Q:How to control the impregnation conditions to obtain the active components of the various distributions of different catalysts

- The amount of active components and additives is an important factor affecting the catalytic performance of the catalyst, the active components, the amount is too small, the activity of course, with the increase in the amount of load, the activity slowly increased, but generally have When the optimum value is greater than this optimum value, the activity is almost constant, and even the metal is sintered due to the excessive load, and the activity and stability of the channel are blocked. Auxiliaries are the same.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000;ISO14001:2004 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Lianyungang Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 135,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

RUBBER VULCANIZING ACCELERATOR·DPG (D)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 120000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords