Pressurized Heat Pipe Solar Water Heater System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 6000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

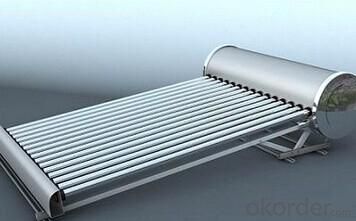

Introduction of Non-Pressure Solar Water Heater:

Non-pressure Solar Heater is one of the most economical solar water heating device with pretty high efficiency at the same time. It consists of hot water storage tank, solar vacuum tubes with mouth plug in storage tank, and bracket supporting tank and tubes.When cold water in evacuated tubes is heated with solar irradiation, as the specific gravities of hot water and cold water are different, hotter water goes upward to storage tank and colder water goes downward to glass tubes. through this continuous circulation, the cold water in storage tank will be gradually heated till sunset.

Specialty:

1. High thermal performance and working temperature: the heat exchanging rate even in winter can up above 55%.

2. Heat collecting efficiency is at least 20% above common solar systems.

3. Work in all day and all season: no matter any corner of the world, this system can work well even -40℃ to avoid the tube freezing problem.

4. Reliability: No water following through the tube, so water scale can not generate and tube cracks could be avoided, the system still can keep working even with some damaged tubes.

5. It can connect with water tap and work automatically with pressure0.6Mpa, bring enjoyable washing experience.

6. Safety: P/T valve would release pressure and temperature to protect tank..

Technical Specification:

1. Outer tank material: SUS304 stainless steel or powder coated color steel

2. Inner tank material: 1.2mm thick SUS304 food grade stainless steel ( Optional material SUS316L)

3. Vacuum tube material: borosilicate glass 3.3; AL-SS-CU absorb coating, with copper heat pipe inside

4. Frame material: 1.2mm thickness stainless steel

5. Insulation material: 55mm thickness polyurethane

6. Suitable for mains pressure water(up to 8 bar/116psi)

7. Easy plug-in installation

8. Install the T/P valve on the pressurized tank

9. Seal material: Stabilized High Temperature Silicon

Outer tank material: SUS304 stainless steel or powder coated color steel

Inner tank material: 1.2mm thick SUS304 food grade stainless steel ( Optional material SUS316L)

Vacuum tube material: borosilicate glass 3.3; AL-SS-CU absorb coating, with copper heat pipe inside

Frame material: 1.2mm thickness stainless steel

Insulation material: 55mm thickness polyurethane

Suitable for mains pressure water(up to 8 bar/116psi)

Easy plug-in installation

Install the T/P valve on the pressurized tank

Seal material: Stabilized High Temperature Silicon

19. Vacuum Tube | 20. Size (mm) | 21. Φ47*1500 / Φ58*1800 / Φ70*2100 | |||||

22. Tube (pcs) | 23. 10 / 12 / 15 / 18 / 20 / 22 / 24 / 30 / 36 / 42 | ||||||

24. Material | 25. Borosilicate 3.3 glass, magnetron spluttering selective coating | ||||||

26. Coating | 27. Single-target AL-N/AL or Three-target AL/N-Cu-SS | ||||||

28. Water Tank | 29. Capacity | 30. 80L ~ 500L for hot water storage tank | |||||

31. Inner tank | 32. Food-grade stainless steel SUS304-2B / SUS316 | ||||||

33. Insulation | 34. High-density polyurethane foam with 70~80 hour heat preservation | ||||||

35. Tank shell | 36. Food-grade stainless steel SUS304-2B | ||||||

37. Bracket | 38. Shaped strong aluminum alloy structure adaptable for flat or slope roof | ||||||

39. Accessories | 40. Anti-aging silicon seals, Dustproof seals, Air-vent cap, Stainless screws | ||||||

41. Auxiliary Devices | 42. Assistant tank, Intelligent controller, Electrical heater, Magnesium anodes | ||||||

43. Tilt Angle | 44. 25 ~ 50° | ||||||

45. Water Output | 46. 45 - 95°C | ||||||

47. Hail Resistance | 48. Φ25mm diameter | ||||||

49. Model Number | 50. Solar Vacuum Tube | 51. Tank 52. Liter | 53. System 54. Liter | 55. Container Loading Qty /sets | |||

56. Size /mm | 57. Qty /pcs | 58. 20GP | 59. 40GP | 60. 40HQ | |||

61. VNS-58SA12-100 | 62. Φ58*1800 | 63. 12 | 64. 100 | 65. 132 | 66. 58 | 67. 119 | 68. 140 |

69. VNS-58SA15-130 | 70. 15 | 71. 130 | 72. 170 | 73. 54 | 74. 108 | 75. 131 | |

76. VNS-58SA18-150 | 77. 18 | 78. 150 | 79. 198 | 80. 43 | 81. 86 | 82. 105 | |

83. VNS-58SA20-170 | 84. 20 | 85. 170 | 86. 223 | 87. 40 | 88. 80 | 89. 97 | |

VNS-58SA24-200 | 24 | 200 | 263 | 35 | 70 | 85 | |

VNS-58SA30-250 | 30 | 250 | 329 | 28 | 56 | 68 | |

VNS-58SA36-300 | 36 | 300 | 395 | 23 | 47 | 57 | |

Product Show

Our Services

1. OEM service

2. Warranty: 5 years

3. Considerable after sale service

Color steel Compact pressure Thermal solar heater

FAQ:

1. What’s the delivery time?

10 days after receiving deposit.

2. How long is the warranty?

5 years for whole system, 1 year for accessory

3. What’s your production capacity?

6000sets/month

4. What’s the MOQ?

1 set.

5. What’s your payment term?

Container: 30% T/T in advance for deposit, 70% T/T before shipment for fist order.

70% T/T after seeing copy of B/L from second order

Sample: 100% T/T in advance

Other choices: L/C at sight.

6. What certifications do you have?

CE, SOLAR KEYMARK, SRCC and etc.

- Q:What is the payback period for installing solar collectors?

- The payback period for installing solar collectors varies depending on a range of factors such as the cost of installation, energy savings, and available incentives. On average, it can take anywhere from 5 to 15 years to recoup the initial investment. However, it's important to note that solar collectors typically have a lifespan of 25 to 30 years, meaning the long-term financial benefits can far outweigh the initial payback period.

- Q:Can solar collectors be used in waste-to-energy plants?

- Solar collectors are indeed capable of being utilized in waste-to-energy plants. These plants convert waste materials into usable energy, usually in the forms of heat or electricity. To supplement the energy production process, solar collectors, such as solar thermal collectors or photovoltaic panels, can be integrated into these plants. The utilization of solar thermal collectors involves capturing solar energy and transforming it into heat. This heat can then be employed in waste-to-energy plants to generate steam, which powers turbines for electricity production. By incorporating solar thermal collectors, waste-to-energy plants can decrease their reliance on fossil fuels, reduce greenhouse gas emissions, and enhance overall energy efficiency. Moreover, photovoltaic panels can also be implemented in waste-to-energy plants to directly convert sunlight into electricity. This electricity can be utilized to operate various functions within the plant or even be fed back into the power grid. By employing solar collectors, waste-to-energy plants can diversify their energy sources and further contribute to renewable energy objectives. Nevertheless, it is crucial to consider various factors such as available space, climate conditions, and cost considerations when integrating solar collectors into waste-to-energy plants. Depending on the specific circumstances, waste-to-energy plants may prioritize other renewable energy sources like wind or biomass. However, the use of solar collectors in waste-to-energy plants presents a practical option to enhance sustainability and minimize environmental impact in energy generation from waste.

- Q:Can solar collectors be used in remote locations?

- Yes, solar collectors can be used in remote locations. Solar collectors are a viable and practical solution for generating electricity or heating water in areas that are not connected to traditional power grids. They can be easily installed and provide a sustainable and reliable source of energy in remote locations where access to conventional power sources may be limited or non-existent. Additionally, their low maintenance requirements make them suitable for remote areas where regular servicing may not be easily accessible.

- Q:Can solar collectors be used in areas with limited access to distribution networks?

- Yes, solar collectors can be used in areas with limited access to distribution networks. Solar energy can be harnessed and used directly on-site, reducing the reliance on distribution networks for electricity supply. This makes solar collectors a viable and sustainable option for off-grid or remote locations with limited infrastructure.

- Q:Can solar collectors be used for generating electricity on spacecraft?

- Yes, solar collectors can be used for generating electricity on spacecraft. In fact, solar panels are a primary source of power for most spacecraft as they convert sunlight into electricity through photovoltaic cells. This sustainable and efficient method allows spacecraft to operate in space where traditional power sources like fossil fuels are not viable.

- Q:Can solar collectors be used in commercial areas?

- Solar collectors have the potential to be utilized in commercial areas. As a matter of fact, an increasing number of businesses are choosing to employ solar collectors to tap into the sun's power for their energy requirements. Solar collectors, including solar panels and solar thermal systems, can be positioned on the roofs, parking lots, or any accessible open space within commercial areas. These collectors convert sunlight into electricity or heat, which can then be employed for various purposes such as powering lighting systems, heating water, or even operating entire commercial operations. The utilization of solar collectors in commercial areas not only aids in reducing electricity expenses and lessening dependence on fossil fuels, but it also presents businesses with an opportunity to contribute to sustainability endeavors and enhance their eco-friendly image. Moreover, government incentives and tax credits for renewable energy installations often make investing in solar collectors financially feasible for businesses. Consequently, solar collectors represent a viable and advantageous choice for commercial areas seeking to embrace clean and renewable energy solutions.

- Q:Can solar collectors be used for heating greenhouse spaces?

- Yes, solar collectors can be used for heating greenhouse spaces. Solar collectors, such as solar thermal panels or solar air heaters, can harness the sun's energy to provide heat for greenhouse spaces. This renewable energy source can help maintain optimal temperatures for plant growth while reducing reliance on traditional heating methods, making it an environmentally friendly and cost-effective solution for greenhouse heating.

- Q:Can solar collectors be used for generating electricity on stadiums?

- Yes, solar collectors can be used for generating electricity on stadiums. They can be installed on the roofs or in open areas surrounding the stadium to harness sunlight and convert it into electricity through photovoltaic panels. This renewable energy source can help reduce the stadium's carbon footprint and provide a sustainable and clean power supply.

- Q:Can solar collectors be used in cement factories?

- Yes, solar collectors can be used in cement factories. Solar thermal technology, such as solar collectors, can be utilized in cement manufacturing processes to provide heat for various purposes, such as preheating raw materials, drying fuels, or powering steam turbines. This can help reduce the reliance on fossil fuels, decrease carbon emissions, and make cement production more sustainable.

- Q:What is the impact of altitude on solar collector performance?

- The impact of altitude on solar collector performance is primarily related to the reduction in air density at higher altitudes. This decrease in air density leads to a lower heat transfer coefficient, resulting in reduced heat transfer efficiency of the solar collectors. Additionally, the decrease in atmospheric pressure at higher altitudes can affect the boiling point of the heat transfer fluid, potentially leading to operational challenges. However, the impact of altitude on solar collector performance can vary depending on factors such as the type of collector, location, and design considerations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pressurized Heat Pipe Solar Water Heater System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 6000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords