Prefab House Concrete Purline Casting Mould

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prefab House Concrete Purline Casting Mould

1. Structure of Prefab House Concrete Purline Casting Mould:

Prefab House Concrete Purline Casting Mould is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Prefab House Concrete Purline Casting Mould:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Prefab House Concrete Purline Casting Mould Images:

4. Prefabricated Concrete Purline Compression Molding Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

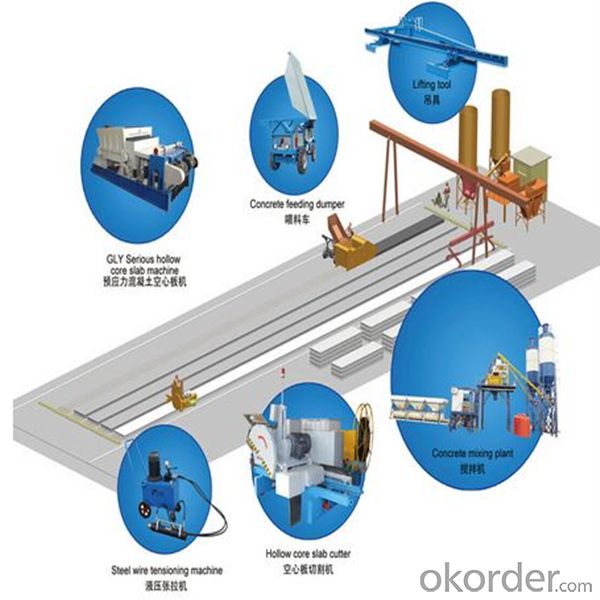

Production Process

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Our Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

8. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the <Chinese Prestressed Concrete Hollow Core Slab Standard>.

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

9. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q:Is there any common pattern between the two?While several ultra-Islamist countries have draconian laws to punish everyone who slanders god, CCP is known to punish everyone who slanders the Chinese Communist Party. CCP often resorts to informal detentions, punishments and disappearances which are completely outside the law, and so offer the government deniability and the victim no protection whatsoever.Do the Chinese people find any commonality between the Blasphemy Laws practiced in Islamist countries and the draconian policies of CCP?

- Have you also noticed that these religious fanatics use God to justify their actions rather than the laws that benefit the people? It is similar in that China uses the welfare of the state rather than a god to get to the same end, and that is domination of the masses.

- Q:I want to be an engineer who works with microchips and things like that. Are there any small projects and things which I could do at home (spending less than $100-200) just to get a feel for things?

- As stated by others, microchips and machinery are built in totally different ways. There are a number of microcontrollers on the market that give you access to hardware control while learning the software aspects, which puts off the tricky interfacing questions till later. Parallax BASIC Stamp devices and Raspberry Pi have gotten a fair amount of attention and support, the former in various robotic device projects while the latter has stronger support for communications, it seems to me

- Q:Royal Co. acquired new machinery with a list price of $700,000. At the date of Purchase they received a $7,000 cash discount and paid $2,000 of delivery charges. Installation and worker training costs were $46,000 and $14,000 respectively. During installation, worker negligence caused $15,000 damage to other machinery in the factory building. What is the acquisition cost for the machinery?I am unsure what to include, deduct or add in the calculation. Any help would be great!

- Acquisition Cost Accounting

- Q:What is the best way to invent something? Like and industrial piece of machinery.?

- Have imagination, patience and lots of money.

- Q:i'm a Taiwan heavy industry and science instrument field agent. i hope i can use this website to contact factory owner to agent ther'e product.

- Best of Luck.

- Q:why on ship machinery's are installed forward-aft & not port starboard?

- Depends on the designer... Machinery can be placed athwart-ship , fore and aft or a combination of the two if more than two pieces of the same type of equipment are installed. For athwart-ship placement at a given frame location, the numbering starts at the centerline and working outward even numbers go on the port and odd numbers on the starboard. For/Aft placement the numbering increases from bow to stern. Machinery is alway labeled starting at 1 even if it is located on the port side as would be the case of a single unit or the first forward most unit with additional units aft. Some factors that determine how and where machinery is placed include: size, weight, access for operation and repair, how critical the equipment is in relation to safe operation of the ship (number of backups or units to be run in parallel)

- Q:Jan. 1 Retired a piece of machinery that was purchased on January 1, 2001.The machine cost$62,000 on that date. It had a useful life of 10 years with no salvage value.June 30 Sold a computer that was purchased on January 1, 2008.The computer cost $40,000. Ithad a useful life of 5 years with no salvage value.The computer was sold for $14,000.Dec. 31 Discarded a delivery truck that was purchased on January 1, 2007. The truck cost$39,000. It was depreciated based on a 6-year useful life with a $3,000 salvage value.InstructionsJournalize all entries required on the above dates, including entries to update depreciation,where applicable, on assets disposed of. Ingles Company uses straight-line depreciation. (Assumedepreciation is up to date as of December 31, 2010.)

- You didn't state the year in which these transactions occurred. I'm assuming 2011. Jan. 1, 2011 Retired a piece of machinery that was purchased on January 1, 2001.The machine cost $62,000 on that date. It had a useful life of 10 years with no salvage value. Annual depreciation = $62,000/10 = $$6,200 By December 31, 2010, the machinery would be fully depreciated. Dr Accumulated depreciation $62,000 Cr Machinery $62,000 June 30, 2011 Sold a computer that was purchased on January 1, 2008.The computer cost $40,000. It had a useful life of 5 years with no salvage value.The computer was sold for $14,000. Annual depreciation = $40,000/5 = $8,000 By December 31, 2010, the accumulated depr account would have a balance of $24,000 (3 yrs) You need to depreciate another 6 mths to June 30, 2011 Dr Depreciation expense $4,000 Cr Accumulated depreciation $4,000 after which the accum. depr. would be $28,000, and the carrying amount $12,000. If it was sold for $14,000, there would be a gain of $2,000 Dr Accum depr $28,000 Dr Cash $14,000 Cr Computer $40,000 Cr Gain on disposal of computer $2,000 Dec. 31, 2011 Discarded a delivery truck that was purchased on January 1, 2007. The truck cost $39,000. It was depreciated based on a 6-year useful life with a $3,000 salvage value. Annual depr = ($39,000 - $3,000)/6 = $6,000 By December 31, 2010, the accum. depr. = $24,000 (4 yrs) You need to update depreciation by 1 yr Dr Depreciation $6,000 Cr Accum depr - Truck $6,000 after which the accum depr = $30,000, and the carrying amount = $9,000 Dr Accum depr $30,000 Dr Loss on scrapping of vehicle $9,000 Cr Vehicle $39,000

- Q:Women: Do you like to operate machinery? Weedeaters? Lawnmowers? Tillers? Tractors? Etc?

- Where I'm at, alot of women seem to like to mow and weed their own land. Where I am from, we usually hire people for that sort of thing. Anyway, that's a nooooo from me. I let my husband do it.

- Q:I am making a hypothetical business for school and have decided to create a business that makes whey protein powder from the whey left over from the making cheese. I have searched all over the net but I cant find any information on the machinery used in this process. Can anyone help

- nope

- Q:what are the auxiliary machinery found in ships?

- It's not that I think this kind of teaching should continue, but it would be a shame to have to repeat the course. I'm not sure what the school administration would decide. (It is a really bad test. I know nothing about your subject, but it is very hard to read and understand).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prefab House Concrete Purline Casting Mould

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches