Plastic Black Masterbatch Color & Additive Master Batch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

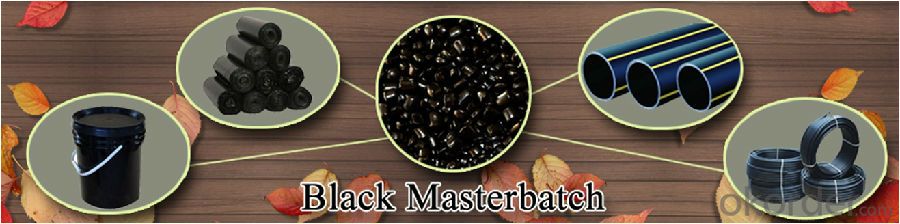

Black masterbatch is made of high tinting strength carbon black and virgin pe resin and additives production

Additive amount:2%-30% is recommended. Or adjust the dosage as per your products performance

Application:Blowing film,injection molding,pipe and wire drawing

Packaging:Paper-plastic compound bags,or PE bags,25kg net weight/bag.

Advantage of Black Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of Black Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

Product Pictures of Black Masterbatch

- Q:What are the bulk density, size and moisture content of the general plastic material?

- The bulk density has something to do with particle size. The larger the particle, the smaller the bulk density of the same composition. This is because the accumulation of material quality, material bulk density = space volume. The bulk density is pseudo density.

- Q:What kind of material is the raw material of plastic pipes?

- The raw material of plastic pipe is mainly based on the plastic tube type, type, polyethylene plastic pipe (PE) is the raw material of ethylene, polyvinyl chloride (PVC) material is polyvinyl chloride, polypropylene pipe (PB) is the raw material propylene.

- Q:What is the specific material for plastic pallets?

- Plastic pallets vary greatly in price, and cheap plastic pallets are made of recycled plastic waste after processing;There is to see the pallet bearing, and see if it is necessary to strengthen the steel bar, if the reinforcement of the bearing, certainly no problem, the price will be relatively high;Plastic tray overall is good, easy to clean, light weight; purchase well, choose a few suggestions tray manufacturers, so that they were bidding competition, so the price can also press down some

- Q:PP plastic stool surface with those raw materials, what is the ratio?

- PP has good stress cracking resistance and has a high bending fatigue life, commonly known as "fold gum"".The comprehensive performance of PP is better than that of PE.

- Q:Can PE material be used as food grade plastic?

- Plastic film PE the main consumption areas, because of its more and more used in consumption and transportation, the development of the relationship between demand and the overall economic situation is bigger, basically maintain a slightly higher than the national GDP growth, the growth momentum of stable existence of rigid demand. From the flexible packaging film production statistics, since 2006, the average increase rate of 13%, but also confirms the steady growth of plastic film. Another important consumption area of polyethylene is plastic pipe, and its output increases with the pace of urbanization in China, and the increase of municipal pipeline construction projects is increasing. In the next few years, the municipal water supply and drainage, gas pipelines, and urban underground power, communication, sheathing and pipelines will continue to be the focus of development in recent years.

- Q:PVC what is the difference between raw and recycled raw materials?

- Generally recycled material will contain a lot of impurities, so some characteristics of raw materials are weakened, such as poor color, impure yellow easily; ash produced after combustion.

- Q:Aluminum Alloy door corner with what plastic raw materials do?

- Nylon two times, generally eight thousand and one hundred tons of good, I do the mold, and my customers are using this material

- Q:What raw material produces the plastic to the human body not to harm, to the environment does not have the pollution?

- Starch plastics containing starch in more than 90%, add other components also can be completely degraded, there are Japan Sumitomo Business Corporation, American Wamer-Lamber company, Italy Ferrizz company claims of success starchier in 90% to 100% of full starch plastics, in (January ~ 1) completely biodegradable without leaving any trace, no pollution, can be used in the manufacture of various containers, bottles, films and garbage bags etc. all starch plastics production principle is that the starch molecular allostent anddisorderly change formed with thermoplastic starch resin, also known as the thermoplastic starch plastics. The molding process can be used in traditional plastic processing equipment. With starch as the potential advantages of development of bio degradable plastics raw materials: starch has biodegradability completely in various environments; plastic in the degradation of starch molecules or after ashing, the formation of two oxygen Carbon gas, without soil or air poison; take appropriate technology to make starch thermoplastic after mechanical properties can reach for manufacturing plastic material; starch is a renewable resource, inexhaustible, pioneering starch utilization is conducive to rural economic development. That is, starch plastics production in China of vast the majority of starch filled plastics, is added in a certain proportion of polymer materials in non biodegradable starch, resulting in the collapse of material physical property through biodegradation of starch, prompted a large number of end groups that exposed to oxidative degradation, but the rest of the "collapse" after the PE, PVC and so on are not always possible degradation the residue in soil, of course, days and months multiplying will cause pollution, so the foreign ownership for such products will be eliminated.

- Q:What are the POE plastic raw materials?

- Poe plastic raw materials are polymers of ethylene and butene, polymers of ethylene and isobutene.

- Q:I do PA, PC, PP and other plastic raw materials can be used in the eye frame and lens it

- In general, the lenses of PC need to be covered with scratch resistant protective films, which will be sufficient for better aging, and most lenses for children.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Black Masterbatch Color & Additive Master Batch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords