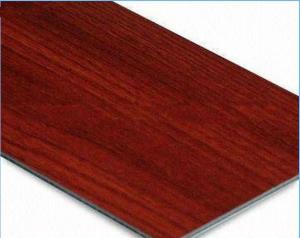

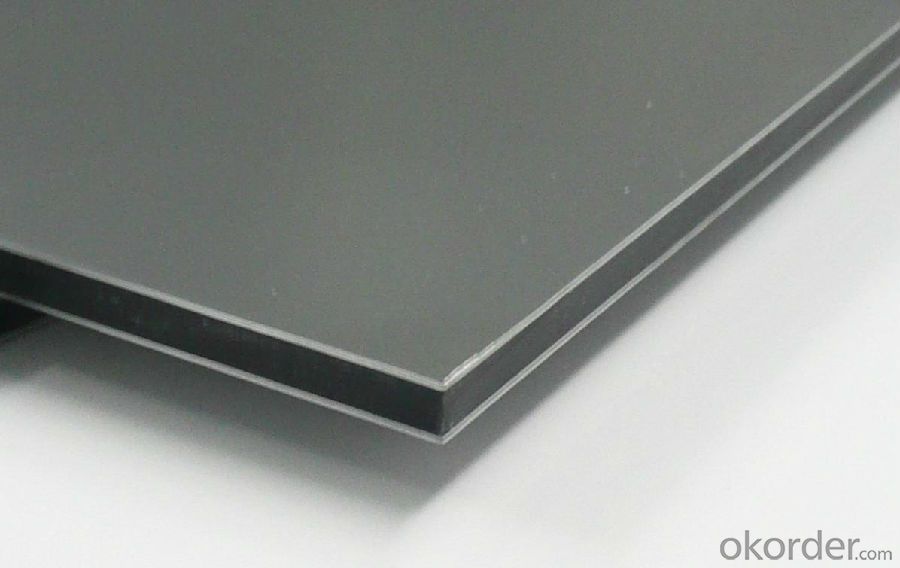

PE PVDF aluminium composite panel exterior cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

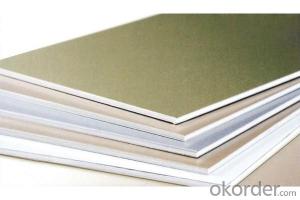

PE PVDF aluminium composite panel exterior cladding

| PRODUCT PARAMETER | |||||

| Product name | Pvdf Aluminum Composite Panel | ||||

| Material | Aluminum sheet and PE | ||||

| Brand name | Kaysdy | ||||

| Standard size | 1220mm x 2440mm x 3mm, 1220mm x 2440mm x 4mm | ||||

| Optional size | panel thickness | 3mm - 5.8mm | |||

| aluminum skin thickness | 0.08mm, 0.10mm, 0.12mm, 0.15mm, 0.18mm, 0.21mm, 0.25mm, 0.30mm, 0.35mm, 0.40mm, 0.45mm, 0.50mm | ||||

| panel width | 0.9m - 1.57m | ||||

| 0.9m - 1.57m | |||||

| panel Length | 5.8m is the best choice for container, or according to customized | ||||

| Core layer | Common PE or fireproof PE | ||||

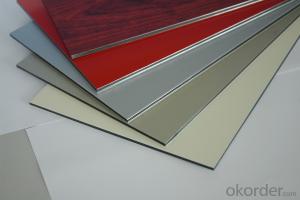

| Surface coating | Polyester(PE) or Fluorocarbon(PVDF) | ||||

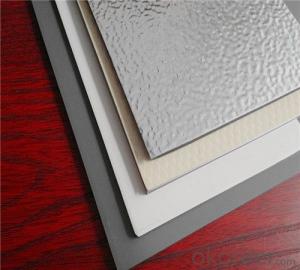

| Special treatment | Brushed, mirror, marble pattern, etc | ||||

| Features | 1. Excellent weather resistance | ||||

| 2. Outstanding characteristics of fireproof | |||||

| 3. High peel strength | |||||

| 4. Multiple colors | |||||

| 5. Easy and rapid installation | |||||

| 6. Environment friendly and Recycle | |||||

| 7. Perfect rigidity | |||||

| 8. Cleanness Maintenance | |||||

Pvdf Aluminum Composite Panel Material

a) Front:Aluminum-alloy sheet coated with fluoro-carbon resin (PVDF) and polyester resin (PE) roasting painting;

b) Core:nontoxic polyethylene;

c) Back:Aluminum-alloy sheet coated with polyester resin painting;

d) Surface finish:Treated with PVDF and PE resin rolling roasting coating;

e) Aluminum alloy sheet thickness: 0.04~0.5mm.

Aluminum Composite Panel Characteristics

Super peeling strength;

Excellent surface flatness and smoothness;

Superior weather, corrosion and pollutant resistance;

Even coating, various colors;

Fireproof, excellent heat and sound insulation;

Superior impact resistance;

Lightweight and easy to process;

Easy to maintain.

- Q:The cost of accessories if the square, then how much money a square ah

- This different manufacturers have different quotes.

- Q:Japan Kobe Steel 5052 aluminum how much money a kilogram?

- Suzhou Hejia constant metal sold in Japan Kobe 5052 aluminum 52 kilograms

- Q:What is a composite function building material?

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials.

- Q:LED lights are normal, why the aluminum plate is also charged. And is 220V of electricity. Really scary.

- Check the line, it may be aluminum-plastic plate cut wire, or nail pierce the wire, resulting in aluminum-plastic board charged.

- Q:Is there a kind of wall called aluminum?

- Outside the aluminum plate it

- Q:What are the differences between fire-resistant aluminum-plastic panels and ordinary aluminum-plastic plates? What are the standards for fire protection on aluminum flooring for business premises?

- For the business of aluminum-plastic panels in the fire on the requirements of at least the flame level or more. Public places are expressly defined as A2.

- Q:Aluminum panels are used in what areas, can not be more detailed.

- Aluminum-plastic composite panel referred to as aluminum-plastic plate, is made by the surface treatment and coated with aluminum paint as the surface, polyethylene plastic plate as the core layer, after a series of process processing complex made of new materials.

- Q:Will the aluminum plate can make a wardrobe?

- Aluminum-plastic plate can be made wardrobe, aluminum-plastic plate easier to clean, you can produce all kinds of patterns.

- Q:What is the difference between stretching aluminum and hot-rolled aluminum? What is the concept of stretching aluminum?

- The production process of aluminum plate is hot rolling, casting rolling, casting, etc., in which the aluminum plate made by hot rolling is superior to the aluminum produced by other processes in the aspects of stretching, oxidation and so on.With the cost of hot plate Production costs are relatively high.

- Q:Hello, how do you contact me? Need green aluminum plate, thank you!

- At present, only the individual manufacturers account for this opportunity because each network needs little, not a lot of manufacturers can not be mass-produced supply.Moreover, many manufacturers now do not have this color, trial capacity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PE PVDF aluminium composite panel exterior cladding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords