NON-Meg. Drill Collar can ensure that hardness, toughness, impact value and corrosion resistance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction:

Nonmagnetic drill collar is made by Nonmagnetic steel, material forging through rigorous analysis of the chemical composition, it can ensure that hardness, toughness, impact value and corrosion resistance can agree API standard. Nonmagnetic drill collar has good low permeability and well machining performance.

2.The size and specification of nonmagnetic drill collar

screw thread no.

| OD | ID内 | Length mm | Shoulder fillet diameter台肩倒角直径 | bending strength ratio 弯曲强度比 | ||

In

| mm | in | mm | ||||

NC23-31 | 79.4 | 31.8 | 9150 | 76.1 | 2.57:1 | ||

NC26-35 | 88. 9 | 38.1 | 9150 | 82.9 | 2.42:1 | ||

NC31-41 | 104.8 | 50.8 | 2 | 9150 or 9450 | 100.4 | 2.43:1 | |

NC35-47 | 120.7 | 50.8 | 2 | 9150 or | 114.7 | 2.58:1 | |

NC38-50 | 127.0 | 5 | 57.2 | 9150 or 9450 | 121.0 | 2.38:1 | |

NC44-60 | 152.4 | 6 | 57.2 | 9150 or 9450 | 144.5 | 2.49:1 | |

NC44-60 | 152.4 | 6 | 71.4 | 2-13/16 | 9150 or 9450 | 144.5 | 2.84:1 |

NC46-62 | 158.8 | 57.2 | 9150 or 9450 | 149.2 | 2.91:1 | ||

NC46-62 | 158.8 | 71.4 | 2-13/16 | 9150 or 9450 | 150.0 | 2.63:1 | |

NC46-56 | 165.1 | 57.2 | 9150 or 9450 | 154.8 | 2.76:1 | ||

NC46-56 | 165.1 | 71.4 | 2-13/16 | 9150 or 9450 | 154.8 | 3.05:1 | |

NC46-47 | 171.4 | 57.2 | 9150 or 9450 | 159.5 | 3.18:1 | ||

NC50-67 | 177.4 | 71.4 | 2-13/16 | 9150 or 9450 | 159.5 | 2.37:1 | |

NC50-70 | 177.8 | 7 | 71.4 | 2-13/16 | 9150 or 9450 | 164.7 | 2.54:1 |

NC50-70 | 177.8 | 7 | 71.4 | 2-13/16 | 9150 or 9450 | 164.7 | 2.73:1 |

NC50-72 | 184.2 | 71.4 | 2-13/16 | 9150 or 9450 | 169.5 | 3.12:1 | |

NC56-77 | 196.8 | 71.4 | 2-13/16 | 9150 or 9450 | 185.3 | 2.70:1 | |

NC56-80 | 203.2 | 8 | 71.4 | 2-13/16 | 9150 or 9450 | 190.1 | 3.02:1 |

209.6 | 71.4 | 2-13/16 | 9150 or 9450 | 195.7 | 2.93:1 | ||

NC61-90 | 228.6 | 9 | 71.4 | 2-13/16 | 9150 or 9450 | 212.7 | 3.17:1 |

241.3 | 76.2 | 3 | 9150 or 9450 | 223.8 | 2.81:1 | ||

NC70-79 | 247.6 | 76.2 | 3 | 9150 or 9450 | 232.6 | 2.57:1 | |

NC70-100 | 254 | 10 | 76.2 | 3 | 9150 or 9450 | 237.3 | 2.81:1 |

279.4 | 11 | 76.2 | 3 | 9150 or 9450 | 266.7 | 2.84:1 | |

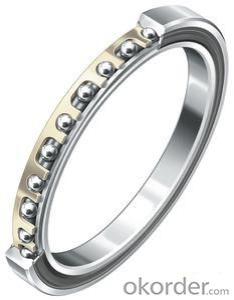

3.Pictures

4.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:Isn't it the middle question or the other question? I'm looking for glfore to do the test. Did anyone do that?

- Possible in the middle. There may be other problems. You can try with them. Excellent

- Q:What's the bearing fillet of the 7003C? Do other bearings have the same fillet?

- In GB/T292-1994 standard, the fillet of 7003C is r0.15 to r0.3; in GB/T292-2007 standard, the fillet of 7003C is r0.10 ~ r0.3.

- Q:CAT can Carter's bearings be replaced by other brands?

- However, you have not heard of the bearing brand, you can consult the SKFFAGNSK agent to check whether there is a product specification

- Q:I need regular manufacturers' agents (with authorized certificates and large scale agents)

- I am Nanjing Yi million strong bearing Co., Ltd. (Jiangyin Office)I am mainly responsible for regional sales in Jiangyin, Zhangjiagang, Jingjiang and so onWe are regular dealers. Here are our certificate of authorization.

- Q:Why are the front fork bearings of the GY6 so difficult to buy, smaller than others?

- if the big nut steering column, in the absence of special sleeve case, can use spanner or hook wrench assembly.

- Q:How can the rod joint bearings be connected with other parts?

- Threaded, rod end joint bearings with internal and external thread points, used in different workpieces. The screw thread is generally used on the fixed shaft, and then the rotating shaft passes through the fish eye bore to form a movable joint part.There is no specific picture, you can refer to the network of rod end joint bearing sample diagram, imagine.

- Q:Machine specific, please describe the specific points

- Many types of bearings. According to the direction of the load it can withstand can be divided into: the radial bearing, also known as radial bearings, bearing radial load. The thrust bearing, and thrust bearing, bear the axial load. The radial thrust bearing, also called centripetal thrust bearing under radial load and axial load at the same time according to the nature of work. The friction bearing can be divided into different sliding friction bearings (the sliding bearing) and rolling friction bearings (the rolling bearing) two categories.Angular contact bearings: ball and raceway nominal contact angle greater than 0 degrees, the rolling bearing and less than 90 degrees. At the same time can bear radial load and axial load. Can work at a higher speed. The larger the contact angle, the axial bearing capacity is higher. The high precision and high speed bearings usually take 15 degrees contact angle in the axial direction. Under the action of force, will increase the contact angle. The axial load of ball bearings can only bear a direction, in radial load, will cause additional axial force. The axial displacement and can limit shaft or shell in one direction. If the duplex mounting, so that a pair of bearing outer ring relatively, i.e. the wide end of the wide end, the narrow end face with narrow end. So to avoid the additional axial force, but also in the two direction of the shaft or shell limit in the axial clearance range.

- Q:I worked in my company bearing the main agent of Harbin SKF FAG NSK NTN the other bearing which have the quality in the first place absolutely genuine fake a lose ten

- Hello, I am here bearing manufacturers, manufacturers direct sales, quality assurance, minimum, reduce the cost of intermediate circulation, welcome inquiry cooperationContact information on personal data

- Q:Must the axle neck fit with the bearings? Is there anything else you can use? Or nothing?

- Not necessarily, depends on the use of configuration, the shaft should generally be equipped with bearings, fixed shaft does not match the bearings..AskIs the rotating shaft, must use bearings? What else can I use in Dingxi?Chasing the answerThe support of the rotating shaft must be the bearing, and the bearing is no more than two kinds of rolling bearings and sliding bearings.

- Q:How are the double seal bearings and other pattern bearings on the specifications and models?

- Angular contact ball bearings - 7;Cylindrical roller bearings - N;Needle roller bearing - NA;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

NON-Meg. Drill Collar can ensure that hardness, toughness, impact value and corrosion resistance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords