New-Type Intelligent Large-Scale Grab Dredger,Dredger

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

- Option:

- Visual simulation system Technical Data

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Profile

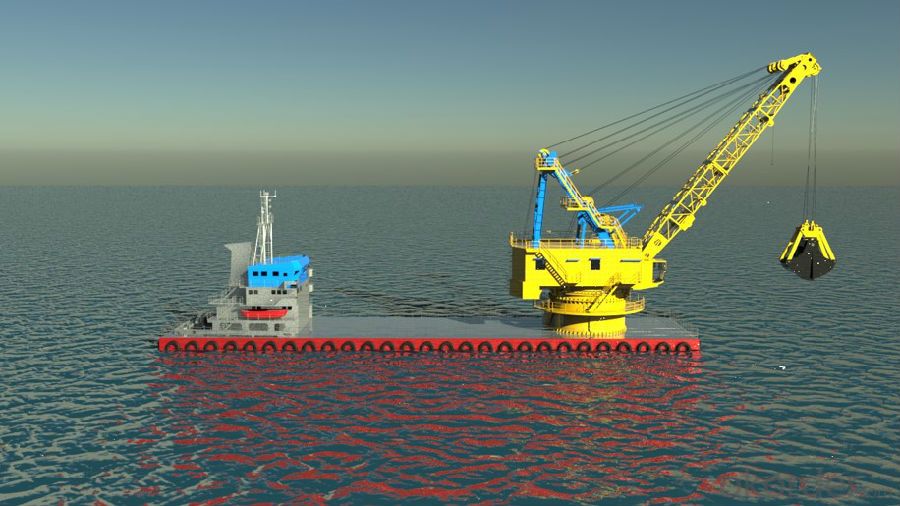

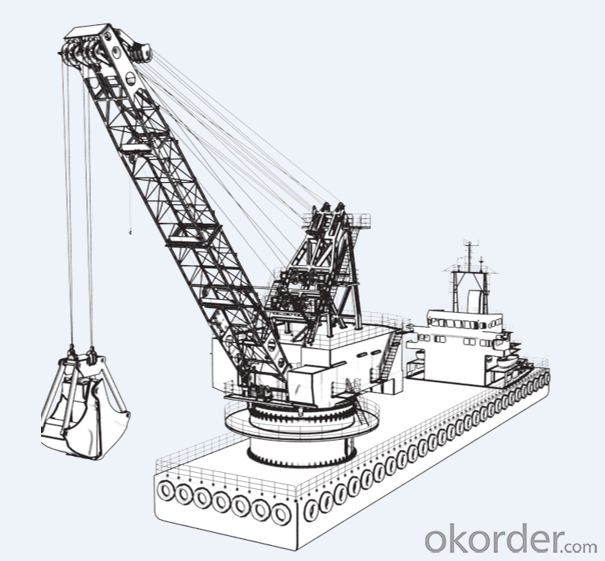

As a kind of working ship, the grapple dredge is mounted on the intelligent grab dredger. The intelligent grab dredger has following dual function, such as dredging operation and lifting the material by hook. The intelligent grab dredger is mainly used in channel dredging, harbor construction, salvage and rescue and other underwater operation. Also, it can be used in handling the material among the ships and bridge construction installing engineering of cross beam over water. By dint of changing the length of the steel cable, it can satisfy the requirement of various digging depth. The max digging depth can reach 70 meter. The intelligent grab dredger can be equipped with crampon and gravel heavy punch. Also the intelligent grab dredger can be considered as crane ship or boat rock cutter for preprocessed, which is thought as multipurpose working ship.

Characteristic

High performance cost ratio

The intelligent grab dredger breaks the monopoly and technical patent barriers of large dredging equipment market, which is monopolized by janpanese SKK, AI and other companies for a long period. The developed new type intelligent dredging equipment that adopts diesel engine-AC variable frequency drive can effectively reduce the purchasing cost and maintaining and using cost for latter period with domestic manufactured parts and auxiliary equipment.

The ship body of the dredger is imported and it is manufactured by domestic manufacturer. And, the dredge is manufactured by foreign countries. The body of the ship needs to be transported foreign country. Then, the dredge can be mounted on the body of the ship. Finally, it can be dragged into domestic to use. The overall new type intelligent dredger is manufactured in domestic, which can quite reduce the cost of the transportation and installation.

Intelligent control

The core of the intelligent grab dredger adopts Siemens S7-300PLC. The ProfiBus-DP system and frequency converter adopts communication junction, which can realize the protection of controlling and fault detect. By means of the predesign and intelligent control model, it can realize the fix dig deep, flat dredging by automatic controlling underwater. The accuracy of the flat dredging is 625px, which is more accurate than imported production(accuracy of flat dredging is 1250px).

Performance parameter

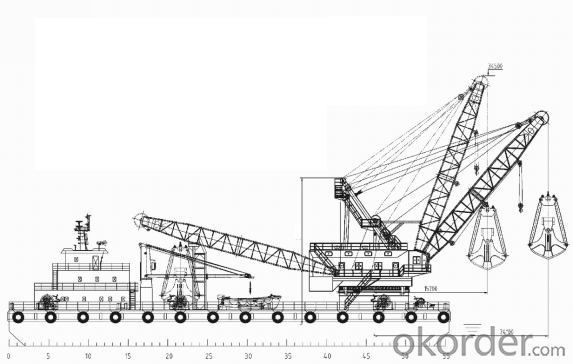

Ø Rated tension force of drum:70t

Ø Length of lazy arm:30m

Ø Working radius:15~23.5m

Ø Operation angle of lazy arm:71°~51°

Ø Applied grab:18m³×45t(dead weight)

Ø Hoisting speed of grab:0~60m/min

Ø Applied area:sheltered waters

Ø Steel cable grab:44ZAB-6×36WS+IWR-1770

Ø Rotating speed:1.2r/min

Ø Time of amplitude of variable of lazy arm:60s

Ø Steel cable of amplitude of variable of lazy arm:34-ZAB6×36WS+IWR-1770

Ø Max.lift:10m(above the water)

Ø The max.depth of dredge:50m(Vertical distance under the water)

Ø Applied temperature:-10~40°

Visualized simulation system

The electrical control system and construction positioning system contains sensing elements, which can realize the collecting data and input the collected data in the visualized simulation system. Together with the data communication technology, computer graphics, computer programming and sensor technology, it can realize visualization of grab underwater.

Convenient operation

It adopts PLC controlling, which has a high control accuracy. It is simple to realize the function that can reduce the numbers of the handling rods and pedal plates and the labor strength of the operator. The flat dredging and fix dig deep has two operation models, such as manual operation and automatic controlling. It has a accurate controlling(accuracy is 625px), which can avoid over dredging phenomenon. It adopts two hand shank and one pedal plate controlling with simple operation and high degree of automation.

Simple and direct maintenance

The overall intelligent grab dredger adopts AC variable frequency common DC bus multi-motor-drive controlling system with simple system and reliability.

The controlling system adopts ProfiBus-DP bus system. The fault of control loop is easy to check, which is convenient to maintain and examine and repair. All of the lifting mechanism and variable frequency mechanism adopt mature and reliable winch system. The rotating system adopts planetary gear system driven by electric motor with mature technology, reliability and convenient maintenance.

Low operation cost and low energy consumption

It adopts diesel generating set to provide power, which is to realize dynamic response. It makes the work of the diesel engine near the optimum efficiency curve, which can provide the fuel economy. It adopts twelve pulse rectification plan that can relieve the interference of the two harmonics and provide force and skill factor and transmission efficiency. It adopts generator sets+motor drive plan. And the overall efficiency can reach 75% which is 5% more than the same kind of equipment of Japan.

High-efficiency

Independent researched and developed intelligent controlling system can realize fix dig deep, flat dredging by automatic controlling, which gives full play to the ability of digging and reduces the time consuming caused by waiting operation and enhances productivity and reduces the manipulation strength. The intelligent grab dredging adopts mature high-power AC variable frequency drive and control technology. The performance of the AC variable frequency is reliable, which can avoid the stop caused by equipment fault and then influence the construction progress. Dual inverter are connected in parallel. And, it is inputted in one electrical machinery. It can make full use of overload capacity. It can realize triple digging overload capacity.

- Q:What is the difference between a cutter suction dredger and a trailing suction dredger?

- TSHD is installed through the chain of dredge bucket will be dug out of the bottom mud, stored on a ship or barge dredger edges.

- Q:How much dredging can the 4000 side /h suction dredge dredge in one day? Soft silt

- The pump in the cabin and the underwater pump are full load. The length of the pipeline is within 3 kilometers, and the depth is about -16 meters. According to the rate of 18 hours per day, the production rate is 61200 according to 3400.The actual amount should be between 45000 and 55000.

- Q:3800m3 cutter suction dredger

- 3800m3 bucket wheel dredger is at the end of the last century according to the Ministry of transportation "based on domestic design and construction, the introduction of equipment key technology policy, the Yangtze River Waterway Bureau presided over the development of construction, Shanghai 708 Institute of design, Wuchang shipyard built China's first inland new dredger. The ship's key power equipment, dredging equipment, hydraulic systems were provided by German SKL company, United States Ellicotte (Aili, Kurt) company, the United States Dennison hydraulic company. This ship has been officially delivered to the Yichang Waterway Engineering Bureau of the Yangtze River. The name of vessel is No. 1.Bucket wheel cutting device in the river near the mouth of the soil suction, and by rotating the bucket wheel by cutting soil and water into high concentration mud, directly transported to the suction suction head of the top tube, rely on the suction centrifugal pump, the suction pipe has certain vacuum. The mud suction head, suction tube at the top end of the suction pipe, through the mud pump pressure after the mud through the mud discharging pipe into the mud barge or transported to the mud field. Through positioning piles, positioning piles, landing gear and traversing winch, the positioning of dredger, longitudinal forward movement and lateral swing of ship are achieved, and the purpose of continuous excavation of river bed soil is achieved.

- Q:Does dredging dredger need relevant qualification?

- But if the local government regulations must be legitimate formal dredging project, estimated to need to apply for a ship's certificate, it is equivalent to a person's identity card! If you need Qingzhou Wynn mine, you can go through the whole process, the relevant costs to consult manufacturers.

- Q:Who knows what's the name of the biggest dredger in China?

- Tianjin Waterway Bureau of the pumping strength slightly stronger its name to "day" at the beginning of the word, is the largest dredger and Tianqi Tianlin, nominal production in my impression is 4200m /h fand the two sister ship, is currently the largest dredger.

- Q:Advantages and disadvantages of trailing suction dredger for trailing suction dredger

- Therefore, the utility model is very suitable for the construction of canals and canals in ports or navigable ships. The disadvantage of a trailing suction dredger is that the bottom of the dredger is hard to dig

- Q:What is the working principle of a cutter suction dredger?

- Construction principle of cutter suction dredger:The dredger is in place, the steel pile excavation construction method, horizontal positioning dredging and filling, it is with a fall in the channel center line of the main hull positioning pile as the center of the rotation, the role of the reamer for traversing on lateral swing in the channel width, the construction method of excavation section of soil layer cutting cutter.

- Q:Who has the construction plan of dredger dredger after dredger dredging and dredging with dredger barge?

- Is it a filling scheme for dredger? How about a suction dredger on the side of Qingzhou? Customer feedback is also OK, you can come and have a lookSpecific contact, see user name, basic data

- Q:Classification of trailing suction dredgers for trailing suction dredger

- Suction dredger is flexible, high efficiency, strong wind waves, suitable for coastal ports, the wide river and ship anchorage operation in large waves and without the cover of coastal and estuarine areas, should choose the self-propelled trailing suction dredger. Soil works suitable for loosening and less than clay hardness.

- Q:The famous type of cutter suction dredger

- MAN provides engines for the world's largest suction hopper dredger.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

New-Type Intelligent Large-Scale Grab Dredger,Dredger

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

- Option:

- Visual simulation system Technical Data

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords