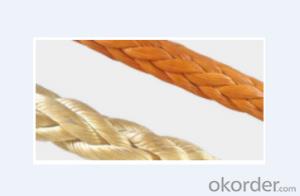

Mooring Rope,material: polypropylene, polyester, nylon, High Molecular Polythylene , aramid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 0 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mooring Rope

Production Scope: The structure of mooring rope can be divided into 3-strand, 6-strand, 8-strand and 12-strand. The raw material includes: polypropylene, polyester, nylon, High Molecular Polythylene (UHMWPE), aramid fibre and synthetic fibre. Diameter scope: Φ6mm ~ Φ140mm are available.

Characteristics of mooring rope: high tensile, low stretch, anti-friction, corrosion resistance, soft and smooth, easyto operate, etc. Mooring ropes are mainly used in shipping equipment, fishing industry, port operation, electric construction, oil exploration, national defense and sports goods, etc.

Textile Sling

Textile sling factory is the largest base for lifting belts in the world with the production capacity over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc.

The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope and traction rope, according to different using environments, different materials would be used, such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene material). We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, aerospace and other fields.

- Q:Where should I pay attention to the formwork?

- When the welded steel bar and the formwork are installed together, the following requirements shall be met:The formwork must be fixed on the joint of the load-bearing welded steel frame;When installing the reinforcing steel formwork assembly, the sling shall be tied up according to the hanging point designed by the template.

- Q:What are the specifications for the rigging?

- Crane users need high quality steel wire rope, it should be long life and high quality stable and reliable wire rope. Fretting fatigue is the main cause of wire rope failure in atmospheric environment

- Q:What does the inspection of rigging involve?

- Phosphating coating of steel wire rope (Chinese patent), wire by Mn and Zn Mn phosphating treatment of steel wire, wear resistance and corrosion resistance of fully, are not easy to wear and corrosion fatigue life of the phosphating coating steel wire rope is the same structure of plain steel wire rope 3 times (laboratory comparable conditions), exceeding imports of steel wire rope, phosphating coating steel wire rope are fully replace all kinds of plain steel wire rope, also be replaced after plating the first pull layer thin zinc galvanized steel wire rope used (through salt spray test the corrosion resistance test), long service life, use lower cost, better quality stability and reliability.

- Q:How do you tie the wire rope?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

- Q:How to choose the right sling?

- Commonly used slings and slings are lifting belts, lifting chains and wire ropes. Slings and slings must be matched with lifting equipment, such as 5 tons or 10 tons. Cranes shall be marked with maximum lifting weight. Lifting belt will not damage the hoisting object but poor wear resistance, easy maintenance but large weight lifting chain, rope buckle range but the broken wire after easily scratch objects and operators, each have advantages and disadvantages, to meet their own needs is the best lifting.Phosphating coating of steel wire rope production technology patent, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just increase the steel wire wear phosphating process, phosphating of steel wire surface after the abrasion resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope (steel wire after phosphating not drawing). The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of plain steel wire rope, wire rope is 2-3 times of imports (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility of. Manganese phosphating is wear resistant phosphating, which can completely solve the wear problem in the use of wire rope.

- Q:Types of slings for slings

- Synthetic fiber slings are mainly made of nylon, polypropylene, polyester, high-strength and high modulus polyethylene fiber for rope and belt slings.

- Q:Ceiling installation does not allow the use of air nails?

- Connection of hanging cup, sling and structural layerOperation method: (1) the main consideration connected with embedded parts and transition piece.In the first layer in embedded iron or wood brick (except water brick). The location shall be accurate and adequate adjustment should be made.The transition in the iron and wooden fittings, so as to adjust the mindware error, and mindware nail, screw, welding, wear.The suspender and the sling are connected with the transition connecting piece.

- Q:What are the precautions for rigging in hoisting works?

- When lifting heavy objects, heavy is prohibited to stand.

- Q:How much is the crane arm of the tower from the residential building recently?

- (1) hook safety device: a sling that prevents the hook from slipping and is automatically slipped from the hook. A spring is arranged at the opening of the hook head to seal the opening; the spring sheet can only be pressed downwards and can not be turned upwards after being put into the sling to prevent the sling from falling off automatically.(2): reel insurance device is effective measure to prevent accidents caused by improper wire rope winding drum out outside. There are different ways to do this. The main reason is that a steel bar is welded outside the drum to restrict the wire rope to move within the reel range.(3) fixed foundation: the depth of digging pit is 600mm, the concrete is poured on the lime soil, the surface is smooth, and the waterproof and earthing protection measures are adopted.

- Q:Does the pressing rope have any influence on the tension value of the wire rope?

- Lifting equipment commonly used wire rope varieties of phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mooring Rope,material: polypropylene, polyester, nylon, High Molecular Polythylene , aramid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 0 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches