Mill Finish Aluminum Coil in Rolls 1000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Mill Finish Aluminum Coil in Rolls 1000 Serie

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

2. Application of Mill Finish Aluminum Coil in Rolls 1000 Serie

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Coil in Rolls 1000 Serie

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

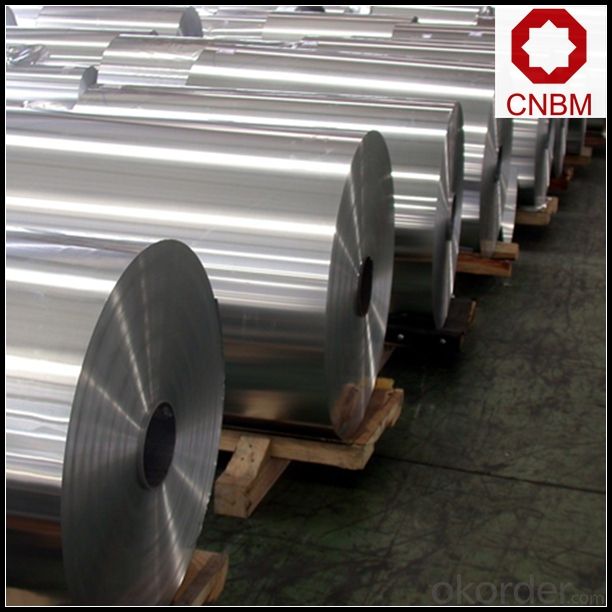

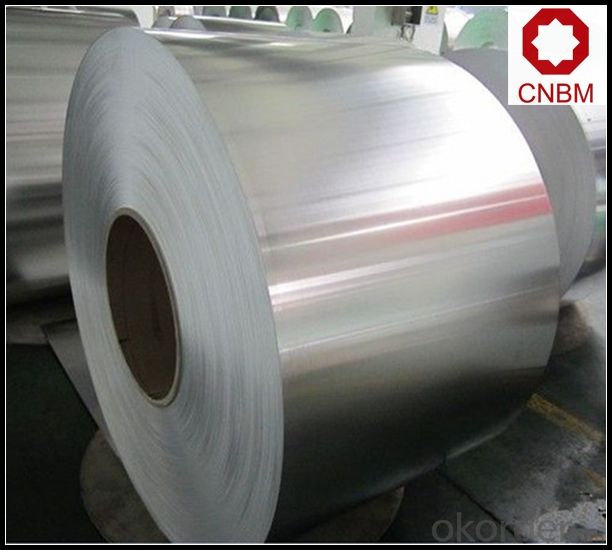

5. Image of Mill Finish Aluminum Coil in Rolls 1000 Serie

6. Package and shipping of Mill Finish Aluminum Coil in Rolls 1000 Serie

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum coils be used for HVAC condenser coils?

- Yes, aluminum coils can be used for HVAC condenser coils. Aluminum is a popular choice for condenser coils due to its excellent heat transfer properties, durability, and resistance to corrosion. Additionally, aluminum coils are lightweight, making them easier to install and transport.

- Q:This is for handling aluminum

- Aluminum as a solid is very safe; although non-nutritious (your body does not require it), its accumulation in tissues is apparently not directly harmful. Individuals who work years of their lives in handling aluminum have no higher incidence of Alzheimer's disease than those that do not. As a powder- particularly very fine powders- aluminum is extremely hazardous with respect to its combustibility, and is used in fireworks (sparklers, for example). When it burns, it is extremely hot, and extinguishing it should not be attempted without training and the correct tools- usually salt or Purple K extinguishing agent. However, it burns so quickly that it will usually be out before attempts can be made.

- Q:How do aluminum coils contribute to the corrosion resistance of marine applications?

- Aluminum coils contribute to the corrosion resistance of marine applications through their inherent properties. Aluminum naturally forms a thin layer of oxide on its surface, which acts as a protective barrier against corrosion. This oxide layer prevents the metal from reacting with water or air, making it highly resistant to rust and corrosion. Additionally, aluminum coils are often coated with protective finishes or treatments that further enhance their resistance to harsh marine environments, ensuring their durability and longevity.

- Q:How do aluminum coils contribute to the thermal conductivity of products?

- Aluminum coils play a significant role in enhancing the thermal conductivity of various products. Due to the exceptional thermal properties of aluminum, coils made from this material are highly efficient at transferring heat. The thermal conductivity of aluminum is much higher compared to other common metals, such as steel or copper. This means that when aluminum coils are used in products, they can quickly and effectively transfer heat from one area to another. For instance, in HVAC systems, aluminum coils are often utilized in air conditioning units. When the refrigerant flows through the coils, the aluminum material rapidly absorbs the heat from the surrounding air. This allows for efficient cooling, as the heat is quickly transferred away from the air and expelled, resulting in a more comfortable indoor environment. Similarly, in heat exchangers, aluminum coils facilitate the transfer of heat between two fluids or gases. The high thermal conductivity of the aluminum allows for efficient heat exchange, ensuring that the desired temperature is achieved in a timely manner. Moreover, aluminum coils are lightweight, which makes them more convenient to handle and install in various products. This characteristic is particularly advantageous in industries such as automotive, aerospace, and electronics, where weight reduction is crucial. In summary, aluminum coils significantly contribute to the thermal conductivity of products by efficiently transferring heat due to their high thermal conductivity properties. Their lightweight nature further enhances their versatility and practicality in multiple industries.

- Q:Can aluminum coils be used for automotive applications?

- Indeed, automotive applications can utilize aluminum coils. Aluminum, being a lightweight and resilient substance, presents numerous benefits within the automotive sector. Its resistance to corrosion proves advantageous for vehicles that face diverse weather conditions. Furthermore, aluminum coils possess commendable thermal conductivity, enabling them to efficiently disperse heat. This attribute proves crucial for automotive utilities like radiators and heat exchangers. Additionally, the ease with which aluminum coils can be molded and shaped renders them suitable for manufacturing a wide array of automotive components. Ultimately, incorporating aluminum coils into automotive applications can lead to reduced weight, heightened fuel efficiency, and improved performance.

- Q:Can aluminum coils be used in the production of window frames?

- Indeed, window frames can be produced by utilizing aluminum coils. Aluminum, as a lightweight and robust substance, finds frequent application within the construction sector owing to its resistance to corrosion and impressive strength. Aluminum coils can be effortlessly molded into numerous configurations, including those suitable for window frames, thereby rendering them an optimal selection for the fabrication of windows. Furthermore, aluminum qualifies as a sustainable material that can be effortlessly recycled, thus establishing it as an eco-friendly alternative for window frame manufacturing.

- Q:Cost of aluminium coil coating fluorocarbon paint?

- Spraying area is the same as above. The warranty period is 7-8 years. This answer is not satisfactory, we can also call Run Hao fluorocarbon Materials Co., Ltd., we will give you a detailed answer.

- Q:How do aluminum coils contribute to fire safety?

- Aluminum coils contribute to fire safety by being non-combustible and having a high melting point. This means that in the event of a fire, aluminum coils will not burn or contribute to the spread of flames. Additionally, they are often used in fire-resistant building materials and electrical wiring due to their ability to dissipate heat efficiently, reducing the risk of fire hazards.

- Q:How do aluminum coils contribute to the aesthetics of a building?

- The versatility, durability, and aesthetic appeal of aluminum coils significantly enhance the aesthetics of a building. Firstly, aluminum coils offer flexibility in achieving the desired aesthetic by easily shaping and forming them into various architectural designs. Whether it's a sleek modern look or a more traditional design, aluminum coils can be customized to meet specific aesthetic requirements. Additionally, architects and designers have a diverse palette of colors and finishes to choose from when using aluminum coils. This wide range of options allows for endless possibilities in creating visually appealing facades and exteriors that match the overall theme or style of the building. Moreover, aluminum's durability and resistance to corrosion make it an ideal material for architectural applications. By using aluminum coils, the exterior surfaces of a building can maintain their aesthetic appeal for an extended period with minimal maintenance required. This long-lasting beauty makes aluminum coils a cost-effective choice for maintaining the aesthetics of a building. Furthermore, aluminum coils contribute to the energy efficiency of a building. They have excellent thermal conductivity, which effectively dissipates heat and reduces energy consumption for temperature control. This energy-saving feature not only enhances the sustainability of a building but also adds to its overall aesthetic appeal by incorporating environmentally conscious design elements. In conclusion, the use of aluminum coils in a building contributes to its aesthetics through design flexibility, a wide range of color and finish options, durability, and energy efficiency. These qualities allow architects and designers to create visually appealing structures that align with the desired aesthetic vision while ensuring long-lasting beauty and sustainability.

- Q:Can aluminum coils be used in the manufacturing of electronic devices?

- Yes, aluminum coils can be used in the manufacturing of electronic devices. Aluminum has excellent electrical conductivity and thermal properties, making it suitable for various applications in electronics, such as in transformers, inductors, and heat sinks. Its lightweight nature and corrosion resistance also make it a popular choice for electronic components.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finish Aluminum Coil in Rolls 1000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords