Mild Steel Double T Equivalent to I Beam Small and Middle Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Mild Steel Double T Equivalent to I Beam Description:

Mild steel double T equivalent to I beam is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Mild steel double T equivalent to I beam is usually made of structural steel and is used in construction and civil engineering. The mild steel double T equivalent to I beam resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Mild steel double T equivalent to I beam theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam Bar IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel I Beam Bar IPE Images:

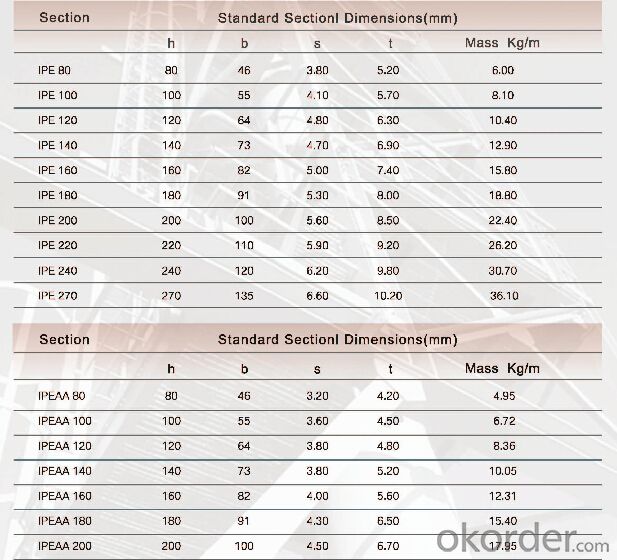

4. Steel I Beam Bar IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:How do steel I-beams perform in high-snow load areas?

- Steel I-beams perform well in high-snow load areas due to their inherent strength and load-bearing capabilities. The I-beam design provides excellent structural support and allows for the distribution of weight across the entire span of the beam. This means that steel I-beams can effectively handle the additional weight and stress caused by heavy snow loads. The high strength-to-weight ratio of steel makes it an ideal material for withstanding snow loads. Steel is much stronger than wood or other building materials, allowing I-beams to maintain their structural integrity under the pressure of heavy snow accumulation. This strength also enables the I-beams to resist bending or buckling, ensuring the stability and safety of the structure. Additionally, steel is a durable material that is highly resistant to corrosion and decay. This is particularly important in high-snow load areas where the snow can melt and create moisture, potentially leading to the deterioration of the structural components. Steel I-beams are not vulnerable to rot or decay, ensuring their long-term performance and reliability in such environments. Furthermore, steel I-beams can be engineered and designed to meet specific snow load requirements. By considering factors such as the anticipated snowfall, snow density, and building design, engineers can calculate the appropriate size and spacing of I-beams to safely support the snow load. This customization ensures that the structure is adequately designed to handle the specific snow load conditions of a given area. In summary, steel I-beams are highly effective in high-snow load areas. Their strength, durability, and ability to distribute weight make them a reliable choice for supporting heavy snow loads. By properly designing and engineering the structure, steel I-beams can provide the necessary stability and safety required in areas prone to significant snow accumulation.

- Q:Can Steel I-Beams be used for retail or shopping centers?

- Steel I-Beams have the capability to be utilized in retail or shopping centers. They are frequently employed in construction projects because of their strength, durability, and versatility. These beams offer exceptional structural support and have the capacity to bear heavy loads, making them appropriate for expansive retail or shopping centers that necessitate open floor plans and high ceilings. Moreover, Steel I-Beams possess high resistance against fire, pests, and corrosion, which is imperative in maintaining the safety and longevity of retail spaces. Furthermore, their capability to span long distances without the need for additional support columns allows for a more flexible and efficient utilization of space, enabling the creation of expansive retail areas. In summary, Steel I-Beams are a favored choice in the construction industry for retail or shopping centers due to their numerous advantages and ability to meet the specific requirements of these types of buildings.

- Q:Can steel I-beams be used in modular construction?

- Yes, steel I-beams can certainly be used in modular construction. Modular construction refers to the process of building structures off-site in a controlled environment, with various components being prefabricated and then assembled on-site. Steel I-beams are commonly used in this type of construction due to their strength, durability, and versatility. Steel I-beams have high load-bearing capabilities, making them ideal for supporting heavy loads in modular construction. They can be used as structural elements for both horizontal and vertical applications, such as floor joists, roof trusses, and support beams. Additionally, their uniform shape and standardized sizing make them easily integrated into modular construction systems. Moreover, steel I-beams offer several advantages in the context of modular construction. They are lightweight compared to other construction materials, which reduces transportation costs and allows for easier assembly on-site. Steel is also highly resistant to various environmental factors, such as fire, corrosion, and pests, ensuring long-term durability and safety of the modular structure. Furthermore, steel I-beams can be designed and manufactured to precise specifications, allowing for efficient and accurate assembly during modular construction. They can be easily interconnected with other modular components, ensuring a strong and stable structure. Additionally, steel I-beams can be customized to accommodate specific architectural and design requirements, making them suitable for a wide range of building types and styles. In conclusion, steel I-beams are commonly used in modular construction due to their strength, durability, versatility, and numerous advantages. Their load-bearing capabilities, lightweight nature, resistance to environmental factors, and ability to be customized make them an excellent choice for integrating into modular construction systems.

- Q:Are steel I-beams cost-effective compared to other materials?

- Yes, steel I-beams are generally considered to be cost-effective compared to other materials in many construction applications. Steel is a highly durable and versatile material that provides excellent structural support and load-bearing capability, making it suitable for a wide range of projects such as bridges, high-rise buildings, and industrial structures. One of the key advantages of steel I-beams is their strength-to-weight ratio. Steel is significantly stronger than materials like wood or concrete, allowing for the design of more efficient and lighter structures. This not only reduces the overall cost of construction but also minimizes the amount of material required, resulting in savings in transportation and labor costs. Additionally, steel is a readily available material with a well-established supply chain, making it more cost-effective compared to other materials that may be less accessible or have limited availability. It also offers flexibility in terms of design, allowing for customization and easy integration with other building components. Moreover, steel I-beams have a long lifespan and require minimal maintenance, which further contributes to their cost-effectiveness. Steel is highly resistant to corrosion, fire, and pests, ensuring durability and longevity. Consequently, the reduced need for repairs or replacements over time translates into long-term cost savings for building owners. However, it is worth noting that the cost-effectiveness of steel I-beams can vary depending on factors such as project requirements, location, and market conditions. While steel is generally affordable, fluctuations in raw material prices and market demand can impact the overall cost. Therefore, it is crucial to evaluate the specific needs of each project and consider the current market dynamics when determining the cost-effectiveness of steel I-beams compared to other materials.

- Q:How do steel I-beams handle vibrations from nearby construction or demolition activities?

- Steel I-beams are specifically designed to handle vibrations caused by nearby construction or demolition activities. Due to their sturdy and rigid structure, I-beams have excellent resistance against vibrations. They are often used in construction projects precisely because of their ability to withstand and dampen vibrations, ensuring the safety and stability of the building or structure.

- Q:How are steel I-beams protected against impact damage?

- Steel I-beams can be protected against impact damage through the use of various methods such as applying protective coatings, installing impact-resistant guards or barriers, using cushioning materials, or employing structural reinforcements. These measures help absorb or redirect the force of impacts, minimizing potential damage to the I-beams.

- Q:Can steel I-beams be used for solar panel supports?

- Yes, steel I-beams can be used for solar panel supports. Steel I-beams are a commonly used structural component in construction due to their high strength and durability. They have the ability to bear heavy loads, making them suitable for supporting solar panels. Additionally, steel I-beams can be easily fabricated and installed, making them a cost-effective choice for solar panel mounting systems. The sturdy nature of steel I-beams ensures the stability and longevity of the solar panel installation, even in harsh weather conditions.

- Q:What are the different grades of steel used in I-beams?

- The different grades of steel used in I-beams can vary depending on the specific application and requirements. However, some commonly used grades include A36, A572, and A992. A36 steel is a low carbon steel that is commonly used in construction and structural applications. It offers good weldability, machinability, and formability, making it suitable for a wide range of projects. A36 steel is often used in I-beams for general structural purposes. A572 steel is a high-strength, low alloy steel that is commonly used in structural applications such as bridges and buildings. It offers excellent strength and toughness, making it suitable for heavy-duty construction projects. A572 steel is available in different grades, with the most commonly used being A572-50, which has a minimum yield strength of 50 ksi. A992 steel is a high-strength, low alloy steel that is commonly used in I-beams for structural applications. It has a minimum yield strength of 50 ksi and a minimum tensile strength of 65 ksi, making it stronger than A36 and A572 steel. A992 steel is often specified for its superior strength and cost-effectiveness in construction projects. Other grades of steel that may be used in I-beams include A500, which is a cold-formed welded and seamless carbon steel structural tubing, and A709, which is a carbon and high-strength low alloy steel structural shape, plate, or bar. It is important to note that the selection of the grade of steel for I-beams depends on factors such as the load-bearing requirements, structural design, and project specifications. Consulting with a structural engineer or steel supplier can help determine the most appropriate grade of steel for a specific application.

- Q:What are the common methods for protecting steel I-beams from corrosion?

- There are multiple approaches to safeguarding steel I-beams from corrosion. These techniques encompass: 1. Application of Coatings: A widely employed method involves coating the steel beams with protective substances. These coatings function as barriers, effectively preventing moisture, oxygen, and other corrosive agents from reaching the steel surface. Common options for coatings include epoxy, polyurethane, and zinc-rich paints. Apart from providing corrosion protection, these coatings also enhance the aesthetic appeal of the beams. 2. Galvanization: Another effective technique entails galvanizing the steel beams. This procedure entails applying a layer of zinc onto the beam surface. The zinc coating acts as a sacrificial layer, corroding instead of the underlying steel when exposed to corrosive elements. Galvanized steel beams are commonly used in outdoor installations or areas with high humidity or exposure to saltwater. 3. Cathodic Protection: This method involves utilizing sacrificial anodes or impressed current to safeguard the steel beams. Sacrificial anodes, typically crafted from zinc or aluminum, are affixed to the beams and corrode in place of the steel when exposed to corrosion. Impressed current systems employ an external power source to generate an electrical current that shields the steel beams from corrosion. 4. Vapor Corrosion Inhibitor (VCI): VCI is an approach that utilizes chemicals or coatings that emit vapors with corrosion-inhibiting properties. These vapors form a protective layer on the steel surface, effectively preventing corrosion. VCI is commonly employed for long-term storage or transportation of steel beams. 5. Regular Maintenance: Consistent inspection and maintenance play a critical role in safeguarding steel I-beams from corrosion. This includes cleaning the beams, eliminating any dirt or debris that may trap moisture, and promptly repairing any damaged coatings or exposed areas. Additionally, implementing a corrosion prevention program, such as routine inspections and maintenance schedules, can aid in identifying and addressing potential corrosion issues before they escalate. It is important to consider various factors, such as the environment, intended use of the steel beams, budget, and desired lifespan when selecting a corrosion protection method. Consulting with corrosion protection experts or engineers can assist in determining the most suitable approach to safeguard steel I-beams in a specific situation.

- Q:Can steel I-beams be used in modular or prefabricated construction?

- Modular or prefabricated construction can indeed incorporate steel I-beams, which are widely utilized owing to their strength, durability, and versatility. These structural components possess exceptional load-bearing capabilities, rendering them suitable for supporting heavy loads in modular or prefabricated buildings. The integration of steel I-beams into the construction process is effortless, enabling the efficient assembly and disassembly of modular components. Furthermore, customization and manufacturing of steel I-beams to specific dimensions ensure the building's structural integrity and stability. On the whole, utilizing steel I-beams in modular or prefabricated construction offers a multitude of advantages, including cost-effectiveness, time-efficiency, and design flexibility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mild Steel Double T Equivalent to I Beam Small and Middle Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords