Melt Extract Stainless Steel Fiber 430

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

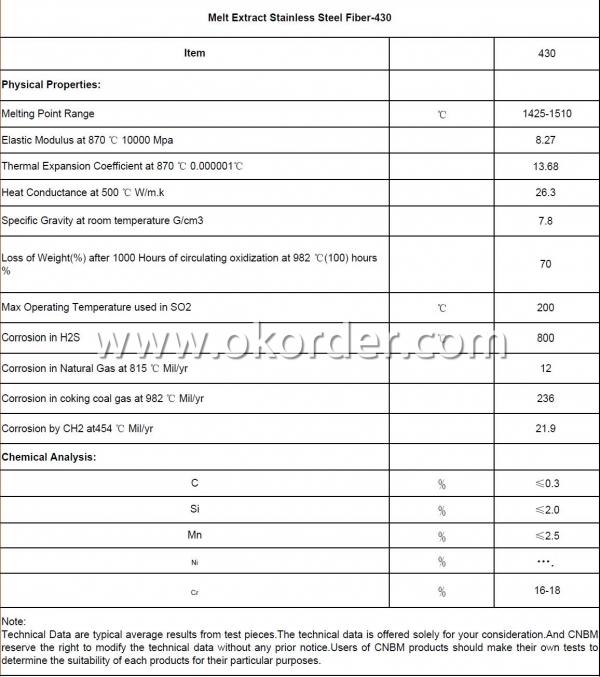

General Information of Melt Extract Stainless Steel Fiber 430

CMAX melt extract stainless steel fibers not only allow for more user-friendly than the stiff cut fibers ,but also have better flow features.Melt extract stainless steel fiber is produced by melting elements in a crucible. A flywheel is then introduced to the crucible and droplets of molten metal are spun into the open air and hardened.The speed of the wheel determines the fiber length. CMAX melt extract stainless steel fiber can increase the lifetime of refractory materials and industrial furnaces by several times, decreasing cost. It has outstanding performances in thermal shock resistance.

Feature of CMAX Melt Extract Stainless Steel Fiber 430

Improve refractories’performance

Improve refractories’longevity

Improve refractories’durability

Significantly reducing downtime and maintance cost

Application of CMAX Melt Extract Stainless Steel Fiber 430

Refractory products

Precast

Castable project

Industrial furnaces

Other refractories project

Our company has success in its melt extract stainless steel fibe rproducts due to their cost-effectiveness and excellent insulating properties. We also have experience in melt extract stainless steel fiber application and would like to assist you in product selection, system design, and installation techniques. Our products of melt extract stainless steel fiber are in good quality and in best price. We can serve many products in your satisfaction.

- Q:What is the long-term performance of melt extract stainless steel fiber in concrete structures?

- The performance of melt extract stainless steel fiber in concrete structures over a long period of time is generally positive. Melt extract stainless steel fiber is renowned for its high tensile strength, resistance to corrosion, and durability, which makes it an outstanding material for reinforcing concrete. Concrete structures can be exposed to different environmental and mechanical strains as time goes on, such as freeze-thaw cycles, chemical contact, and heavy loads. Melt extract stainless steel fiber helps alleviate these problems by enhancing the overall strength and toughness of the concrete. The stainless steel fibers are evenly dispersed throughout the concrete mixture, creating a three-dimensional reinforcement network. This network acts as a secondary reinforcement system, effectively reducing the formation and spread of cracks. As a result, the concrete structure becomes more resistant to cracking, shrinkage, and deformation. In addition, the corrosion resistance of melt extract stainless steel fiber guarantees that the concrete remains safeguarded even in aggressive environments, such as coastal areas or industrial settings. Unlike traditional reinforcement methods like steel rebar, stainless steel fibers do not rust or corrode, thereby preserving the structural integrity of the concrete in the long run. In terms of performance, melt extract stainless steel fiber has undergone extensive testing and has been proven to enhance the flexural and impact strength of concrete structures. It improves resistance to fatigue, abrasion, and impact loads, making it particularly suitable for applications such as industrial floors, pavements, bridge decks, and precast elements. Overall, the long-term performance of melt extract stainless steel fiber in concrete structures is highly dependable. Its ability to reinforce and protect concrete against various strains and environmental factors makes it an excellent choice for construction projects that require durability and longevity.

- Q:Can melt extract stainless steel fiber be used in seismic-resistant concrete structures?

- Yes, melt extract stainless steel fiber can be used in seismic-resistant concrete structures. The fibers enhance the tensile strength and ductility of the concrete, making it more resistant to cracking and improving its ability to withstand seismic forces.

- Q:How does melt extract stainless steel fiber contribute to the crack control of concrete?

- The crack control of concrete is greatly enhanced by the incorporation of melt extract stainless steel fiber. These fibers are included in the concrete mix to reinforce and enhance the overall strength and durability of the structure. When concrete experiences shrinkage due to drying or temperature changes, it has a tendency to crack. However, the inclusion of melt extract stainless steel fibers helps to minimize the width and spread of these cracks. The distinctive properties of stainless steel fibers, such as their high tensile strength, corrosion resistance, and excellent bonding with concrete, contribute to crack control. By forming a three-dimensional network within the concrete matrix, these fibers effectively bridge the cracks and restrict their growth. Furthermore, melt extract stainless steel fibers also enhance the ductility and toughness of concrete as a whole. This means that even if cracks do occur, they are less likely to propagate and cause significant damage to the structure. By acting as reinforcement, these fibers enhance the concrete's ability to withstand the forces that cause cracking. In addition to crack control, the inclusion of melt extract stainless steel fibers also improves the overall performance of concrete by providing better resistance against impact, fatigue, and abrasion. This makes them particularly advantageous in high-stress applications such as industrial flooring, tunnel linings, and precast concrete elements. In summary, the addition of melt extract stainless steel fibers to concrete significantly contributes to crack control by reducing crack width, preventing crack propagation, and enhancing the overall strength and durability of the structure.

- Q:Can melt extract stainless steel fiber be used in dam construction?

- Yes, melt extract stainless steel fiber can be used in dam construction. Stainless steel fiber is known for its high tensile strength, corrosion resistance, and durability, making it suitable for various construction applications, including dams. When added to concrete or other construction materials, stainless steel fibers can enhance the overall strength and longevity of the structure. In dam construction, where the materials need to withstand the pressure of water, the addition of stainless steel fibers can significantly improve the structural integrity of the dam. Additionally, stainless steel fibers can help reduce cracking and enhance the resistance to fatigue and impact, making them an ideal choice for dam construction, where the materials need to withstand various stress factors.

- Q:What is the effect of melt extract stainless steel fiber on the crack resistance of concrete?

- The use of melt extract stainless steel fiber in concrete has a significant effect on the crack resistance of the material. Stainless steel fibers are added to concrete mixes to enhance its overall mechanical properties, including crack resistance. One of the main benefits of using melt extract stainless steel fiber is its ability to improve the tensile strength and ductility of concrete. The fibers act as reinforcement within the concrete matrix, effectively bridging cracks that may occur due to shrinkage or external loads. This bridging effect helps to prevent crack propagation and increase the overall crack resistance of the concrete. The addition of stainless steel fibers also improves the overall durability of concrete. Due to their corrosion resistance properties, these fibers can withstand harsh environments, including exposure to chemicals, moisture, and temperature variations. This durability helps to preserve the integrity of the concrete and reduce the likelihood of cracks forming over time. Moreover, melt extract stainless steel fibers also contribute to the overall energy absorption capacity of the concrete. The fibers absorb energy during loading and distribute it throughout the structure, reducing the concentration of stress in specific areas and minimizing the formation and propagation of cracks. In summary, the inclusion of melt extract stainless steel fiber in concrete significantly enhances its crack resistance. These fibers improve the tensile strength, ductility, and durability of the material, effectively bridging cracks and preventing their propagation. By improving the crack resistance, stainless steel fibers contribute to the overall longevity and performance of concrete structures.

- Q:Can melt extract stainless steel fiber be used in bridge abutments?

- Yes, melt extract stainless steel fiber can be used in bridge abutments. Stainless steel fibers have high tensile strength and excellent corrosion resistance, making them suitable for reinforcing concrete structures. In bridge abutments, which are critical components for supporting the bridge deck and transferring loads to the foundation, the use of stainless steel fibers can enhance the durability and overall performance of the structure. These fibers can effectively improve the crack resistance and flexural strength of the concrete, reducing the potential for cracking and improving the load-bearing capacity of the abutments. Additionally, the corrosion resistance of stainless steel fibers ensures long-term durability in harsh environmental conditions, such as exposure to moisture and deicing salts. Therefore, incorporating melt extract stainless steel fiber in bridge abutments can provide numerous benefits, including increased structural integrity, reduced maintenance needs, and extended service life.

- Q:Can melt extract stainless steel fiber be used in precast bridge column elements?

- Yes, melt extract stainless steel fiber can be used in precast bridge column elements. Melt extract stainless steel fiber is a type of reinforcing material that is commonly used in concrete construction to enhance the overall strength and durability of the structure. It is particularly suitable for precast elements such as bridge columns due to its high tensile strength and corrosion resistance properties. The addition of melt extract stainless steel fiber to the concrete mixture helps to improve the structural integrity and resistance to cracking of the precast bridge column elements, thereby increasing their lifespan and reducing maintenance requirements.

- Q:What is the effect of melt extract stainless steel fiber on the modulus of deformation of concrete?

- Adding melt extract stainless steel fiber to concrete can positively impact the modulus of deformation. Stainless steel fibers are well-known for their high tensile strength and ductility, enabling them to enhance the overall strength and flexibility of concrete structures. When incorporated into concrete, these fibers establish a three-dimensional reinforcement network that evenly distributes stresses throughout the material. This aids in reducing cracks and enhancing the concrete's overall durability. The presence of stainless steel fibers also improves the concrete's modulus of deformation, which measures how much a material deforms when subjected to stress. By reinforcing the concrete, stainless steel fibers prevent excessive deformation and enhance its ability to withstand external loads. Moreover, stainless steel fibers can enhance the post-cracking behavior of concrete. This means that even after the concrete cracks, it can still maintain its structural integrity and load-bearing capacity. In conclusion, the inclusion of melt extract stainless steel fiber in concrete elevates its modulus of deformation, thereby increasing its strength, flexibility, and resistance to cracking. This ultimately leads to improved performance and longevity of concrete structures.

- Q:Can melt extract stainless steel fiber be used in self-compacting concrete?

- Certainly! Melt extract stainless steel fibers prove to be applicable in self-compacting concrete. Self-compacting concrete, known as SCC, possesses a unique fluidity that enables it to effortlessly fill intricate forms without requiring any vibration. This type of concrete is typically employed in circumstances where conventional pouring methods are impractical. The incorporation of stainless steel fibers into SCC offers numerous advantages, such as heightened tensile and flexural strength, improved resistance to cracking, and enhanced durability. Additionally, utilizing stainless steel fibers aids in regulating shrinkage and reducing the occurrence of plastic shrinkage cracking. Melt extract stainless steel fibers are specifically engineered for concrete applications. These fibers are created by melting stainless steel and promptly cooling and solidifying it, resulting in thin, elongated fibers. Ordinarily, these fibers are added to the concrete mixture during the mixing process. By introducing melt extract stainless steel fibers, the overall performance and structural integrity of self-compacting concrete can be significantly enhanced, rendering it an appropriate choice for a wide range of construction projects. Nonetheless, it is crucial to seek advice from a structural engineer or concrete specialist to determine the appropriate fiber dosage and ensure compatibility with the specific SCC mix design.

- Q:Can melt extract stainless steel fiber replace traditional steel reinforcement in concrete?

- Certain applications can see the substitution of traditional steel reinforcement in concrete with melt extract stainless steel fiber. Melt extract stainless steel fiber presents various advantages over traditional steel reinforcement, including increased durability, enhanced crack resistance, and improved corrosion resistance. These fibers, made from stainless steel, are typically incorporated into the concrete mixture during the mixing process. They contribute additional strength and support to the concrete, reducing the reliance on traditional steel reinforcement like rebar or mesh. One of the primary benefits of melt extract stainless steel fiber is its ability to enhance the durability of concrete structures. By evenly distributing stress throughout the concrete, the fibers decrease the likelihood of cracks and improve the overall strength of the structure. This aspect proves especially valuable in applications where the concrete will experience heavy loads or extreme conditions. Another advantage is the improved crack resistance offered by melt extract stainless steel fiber. Acting as reinforcement within the concrete, the fibers inhibit the propagation of cracks and minimize their size. Consequently, this leads to more durable and long-lasting concrete structures. Moreover, melt extract stainless steel fiber provides better resistance to corrosion when compared to traditional steel reinforcement. Stainless steel is renowned for its high level of resistance to corrosion, making it a dependable choice for applications involving exposure to harsh environments or chemicals. Nevertheless, it is crucial to note that melt extract stainless steel fiber may not be suitable for all concrete applications. The decision to replace traditional steel reinforcement with stainless steel fiber should be made based on factors such as specific project requirements, structural design, and the expected loads and conditions the concrete will endure. Consulting with a structural engineer or concrete expert is advised to determine the appropriateness of employing melt extract stainless steel fiber in a particular project.

1. Manufacturer Overview |

|

|---|---|

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 200 Million |

| Main Markets | North America;Asia;Western Europe;Africa;Russia;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Installation guide, OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Melt Extract Stainless Steel Fiber 430

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords