Mechanical Rebar Straightener and Cutter ,straightening machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

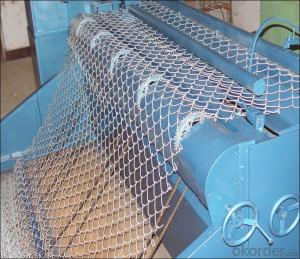

Mechanical Rebar Straightener and Cutter ,straightening machine

Product Feature

1. It has good functions, with high efficiency and less error.

2. Speed can be adjusted. You can cut short material with low speed, and cut long material with high speed.

3. It is suitable for different workers. Unskilled workers could use it with low speed, and skilled workers could use with high speed.

Product Specification/Models

Straightening Scope ø4-ø14mm

Straightening Speed 500 ~ 900m/s

Auto Cutting Length 300-8000mm

Quantity of Cutter 3 sets

Electromotor for Cutting Model Y132M1-6

Rated Power 4.0Kw

Rated Rotational Speed 960r/min

Electromotor for Straightening Rated Rotational Speed 1440r/min

model Y132S-4

Rated power 5.5Kw

Rated Voltage 380V

Rated Frequency 50Hz

External dimensions 9860 * 1010 * 1365mm

Net weight 1070 Kg

Application

The machine is used to straighten and cut t round bar (steel rod).

Payment

T/T L/C

Delivery

Within one week

Origin

China

Minimum Order

1 set

Packaging

Plywood case

Remarks

OEM & ODM, Buyer Label can be provided.

Packing

Plywood Case

Payment

T/T L/C

Delivery

Within one week

Origin

China

Minimum Order

1 set

Packaging

Plywood case

Remarks

OEM & ODM, Buyer Label can be provided.

Company Direction

We are China professional manufacturer and system solutions provider of rebar connection machines,rebar processing machines and small road machines.

Founded in the 1990s. For 20 years, it has been focusing on the research, production and sales of rebar connection machines and rebar processing machines. The company is located in the capital of China - Beijing, has strong technical force, complete processing equipment and testing means. All the products are optimized by microcomputer design to reach the advanced level of industry.

- Q:Can metal straightening machinery be used for straightening pipes or tubes?

- Metal straightening machinery has the capability to straighten pipes or tubes. Its purpose is to rectify any distortions or curves in metal items, including pipes and tubes. Through the application of controlled force and pressure, the machinery is able to progressively align the pipes or tubes, restoring them to their initial form. This proves extremely advantageous in sectors like construction, plumbing, and manufacturing, where the efficiency of operations greatly relies on straight and accurately positioned pipes and tubes. Moreover, metal straightening machinery exhibits versatility as it can accommodate different sizes and types of pipes and tubes, thereby establishing itself as a multifunctional instrument for straightening metal objects.

- Q:Can this machinery be used for straightening metal with internal cracks or fractures?

- Unfortunately, this machinery is not suitable for straightening metal that has internal cracks or fractures. Typically, this equipment is used for bending or shaping metal, rather than repairing or fixing internal cracks or fractures. To resolve such issues, specialized techniques like welding or heat treatment may be necessary.

- Q:Can metal straightening machinery be used for hot or cold straightening?

- Yes, metal straightening machinery can be used for both hot and cold straightening.

- Q:Can metal straightening machinery be used for both industrial and artisanal purposes?

- Yes, metal straightening machinery can be used for both industrial and artisanal purposes. Industrial applications may include mass production and large-scale metal fabrication, while artisanal purposes may involve smaller-scale projects and customization. The versatility of metal straightening machinery allows it to cater to various needs and scales of metalworking.

- Q:Can metal straightening machinery be used for straightening automotive components?

- Yes, metal straightening machinery can be used for straightening automotive components. Metal straightening machinery is designed to straighten various types of metal objects, including automotive components. These machines utilize hydraulic or mechanical force to apply pressure and reshape the metal back to its original form. Automotive components such as frames, panels, and bars can be straightened using these machines, ensuring that the components are in proper alignment and fit for use. Metal straightening machinery provides precision and accuracy in straightening automotive components, helping to restore the integrity and functionality of the parts.

- Q:Can metal straightening machinery straighten bent or twisted metal parts?

- Yes, metal straightening machinery is designed specifically to straighten bent or twisted metal parts. This machinery uses various techniques, such as hydraulic or mechanical force, to apply pressure and reshape the metal back to its original form. The process involves clamping the bent or twisted metal part securely in the machinery and then gradually applying force to straighten it. This machinery is often used in industries like automotive, aerospace, construction, and manufacturing, where precision and accuracy in metal parts are crucial. Metal straightening machinery provides an efficient and effective solution for restoring bent or twisted metal parts, saving time and resources compared to manual methods.

- Q:What are the common safety protocols for handling warped materials with metal straightening machinery?

- When handling warped materials with metal straightening machinery, it is important to follow certain safety protocols to ensure the well-being of individuals and prevent any accidents or injuries. Some common safety protocols for handling warped materials with metal straightening machinery include: 1. Personal Protective Equipment (PPE): All personnel involved in the handling process should wear appropriate PPE, such as safety goggles, gloves, and steel-toed boots, to protect themselves from potential hazards. 2. Inspection and Maintenance: Regular inspections and maintenance of the metal straightening machinery should be conducted to ensure it is in proper working condition. Any faulty or damaged parts should be repaired or replaced immediately to prevent accidents. 3. Training and Education: Operators and personnel responsible for handling warped materials should receive proper training and education on the safe operation of the metal straightening machinery. They should be familiar with the equipment's controls, emergency shutdown procedures, and any specific safety precautions related to handling warped materials. 4. Secure the Work Area: Prior to handling warped materials, the work area should be properly prepared. This includes clearing any clutter or obstacles, ensuring adequate lighting, and marking off any hazardous areas to prevent slips, trips, or falls. 5. Load Capacity: It is crucial to understand the load capacity of the metal straightening machinery and ensure that it is not exceeded. Overloading the machinery can lead to structural failures or uncontrolled movements, posing significant safety risks. 6. Material Handling: Warped materials should be lifted, positioned, and secured properly when using metal straightening machinery. The use of lifting equipment, such as cranes or forklifts, should be considered when dealing with heavy or large pieces. 7. Emergency Stop: Operators should be aware of the location and operation of the emergency stop button or switch on the metal straightening machinery. This allows them to quickly shut down the equipment in case of any emergencies or unsafe conditions. 8. Communication: Clear communication between the operator and other personnel involved in the handling process is vital. Hand signals or radios should be used to ensure everyone is aware of the ongoing operations and any potential dangers. 9. Regular Breaks: Operators should take regular breaks to prevent fatigue, as tiredness can lead to decreased concentration and an increased risk of accidents. 10. First Aid and Emergency Response: Adequate first aid supplies should be readily available, and personnel should be trained in basic first aid and emergency response procedures. In the event of an accident or injury, prompt medical attention should be sought. Always remember to prioritize safety when handling warped materials with metal straightening machinery. By following these common safety protocols, the risk of accidents or injuries can be significantly reduced.

- Q:What is the maximum force that metal straightening machinery can exert?

- The specific type and model of metal straightening machinery determine the maximum force it can exert. Typically, these machines are designed to apply high levels of force to effectively straighten and reshape metal materials. Some machines can exert forces ranging from a few hundred pounds to several thousand pounds or more. The maximum force depends on the machinery's capacity, power, and the type and thickness of the metal being straightened. To determine the maximum force capacity, it is essential to refer to the manufacturer's specifications and guidelines for the specific machinery in question.

- Q:Are there any limitations to using metal straightening machinery?

- Yes, there are several limitations to using metal straightening machinery. Firstly, the size and weight of the metal being straightened can be a limitation. Most metal straightening machinery is designed for specific sizes and weights of metal. If the metal being straightened is too large or heavy, it may not fit or be too difficult to handle with the available machinery. Secondly, the type of metal being straightened can also be a limitation. Different metals have different properties and require specific techniques and machinery for straightening. Some metals may be too brittle or too malleable to be effectively straightened using standard machinery. Another limitation is the complexity of the shape being straightened. Metal straightening machinery is typically designed for straightening simple shapes such as flat sheets or rods. If the metal has complex curves, angles, or intricate designs, it may not be possible to fully straighten it using standard machinery. In addition, the cost of metal straightening machinery can be a limitation. These machines are often large and expensive, requiring a significant investment. Small businesses or individuals may find it financially challenging to acquire or maintain such machinery. Furthermore, metal straightening machinery requires skilled operators. Proper training and expertise are necessary to effectively and safely operate the machinery. Without skilled operators, there is a risk of damaging the metal or causing accidents. Lastly, metal straightening machinery can have limitations in terms of speed and efficiency. Depending on the specific machinery, it may have a limited throughput or take a significant amount of time to straighten each piece of metal. This can be a constraint in industries where high volumes or quick turnaround times are required. Overall, while metal straightening machinery is a valuable tool for many industries, there are limitations in terms of size, type of metal, complexity, cost, required expertise, and speed. It is important to consider these limitations and assess whether alternative methods or specialized machinery are needed for specific metal straightening requirements.

- Q:Can metal straightening machinery be used for straightening metal forgings with varying shapes?

- Yes, metal straightening machinery can be used for straightening metal forgings with varying shapes. Metal straightening machinery is designed to manipulate and reshape metal components, including forgings, to achieve desired straightness and dimensional accuracy. These machines utilize various techniques such as bending, rolling, and pressing to correct any deformations or misalignments in the metal forgings. Whether the metal forgings have irregular shapes or complex geometries, the adjustable features and customizable settings of metal straightening machinery allow operators to effectively straighten them. By applying controlled forces and pressures, the machinery can gradually and precisely correct any deviations, ensuring that the forgings meet the required specifications. Therefore, metal straightening machinery is versatile and capable of straightening metal forgings with varying shapes, making it an essential tool in the metalworking industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mechanical Rebar Straightener and Cutter ,straightening machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords