Low Smoke Halogen Free Flame Retardant Polyolefin Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LSZH compound:

1. competitive price

2. 30 years of experience

3. stable quality

4. customized product

LSZH compound:

1. Applications and cable specifications of LSZH compound:

Common jacket for flame retardant wires and cables which operation temperature is at 90 degree C.

2. Description of LSZH compound:

Thermoplastic, low-smoke, halogen-free and flame retardant POE jacket compound, based on POE resin, is produced and pelletized by special technology with adding special modifier, flame retardant, anti-oxidant and other special additives.

3. Processing of LSZH compound:

The compound can be processed with conventional extruders, and the screw with a minimum 20:1 L/D and a compression ratio of 1.2 is recommended.

The following temperature(°C) profile of extruder is recommended:

| Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

| temperature degree C | 140 | 145 | 150 | 150 | 145 | 145 |

Note:Compound should be dried at 70-80 degree C before use, which has been stored more than two months.

4. Storage and transport of LSZH compound:

Packing: 25kg/bag, PE membrane inside bag and craft outside bag.

Avoiding in direct sunlight and weathering.

Storage place should be clean, cool, dry and ventilated.

5. Properties of LSZH compound:

| Item | Unit | DW9021 | DW9023 | DW9023B | DW9023C | ||||

| Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

| Density | g/cm3 | -- | 1.46 | -- | 1.48 | -- | 1.5 | -- | 1.5 |

| Hardness | Shore A | -- | 95 | -- | 95 | -- | 95 | -- | 96 |

| Tensile Strength | ≥MPa | 9 | 12.5 | 9 | 12.5 | 9 | 12 | 9 | 10.5 |

| Elongation at Break | ≥ % | 125 | 200 | 125 | 190 | 125 | 230 | 125 | 150 |

| Thermal Aging | degree C * h | 110×240 | 110×240 | 110×240 | 110×240 | ||||

| TS/EB Retention | ≥ % | 75/75 | 105/86 | 75/75 | 110/82 | 75/75 | 104/91 | 75/75 | 115/85 |

| Hot Deformation 80 degree C 4(6)h | ≤ % | 50 | 22 | 50 | 21 | 50 | 24 | 50 | 16 |

| Impact Brittleness Temperature | ≤degree C | -20 | pass | -20 | pass | -20 | pass | -20 | pass |

| Volume Resistivity, at 20 degree C | ≥Ω*m | 1.0×1011 | 1.1×1012 | 1.0×1011 | 2.3×1012 | 1.0×1011 | 1.8×1012 | 1.0×1011 | 2.9×1012 |

| Oxygen Index | ≥ | 33 | 33 | 35 | 36 | 37 | 38 | 38 | 40 |

| Smoke Density Flaming | ≤ | 100 | 66 | 100 | 62 | 100 | 51 | 100 | 54 |

| Non flaming | ≤ | 200 | 135 | 200 | 132 | 200 | 143 | 200 | 125 |

| Acidity of gases evolved (pH) | ≥ | 4.3 | 5.3 | 4.3 | 5.7 | 4.3 | 6.1 | 4.3 | 6.1 |

| Conductivity of gases evolved | ≤μs/mm | 10 | 1 | 10 | 1 | 10 | 1 | 10 | 1 |

| Content of halogen acids | ≤ mg/g | 5 | 1 | 5 | 1 | 5 | 0.9 | 5 | 0.8 |

| Toxicity Index | ≤ | 2.5 | 1.2 | 2.5 | 1.1 | 2.5 | 1.7 | 2.5 | 1 |

| Thermal Impact Test Condition 150 degree C*1h | No cracking | Pass | No cracking | Pass | No cracking | Pass | No cracking | Pass | |

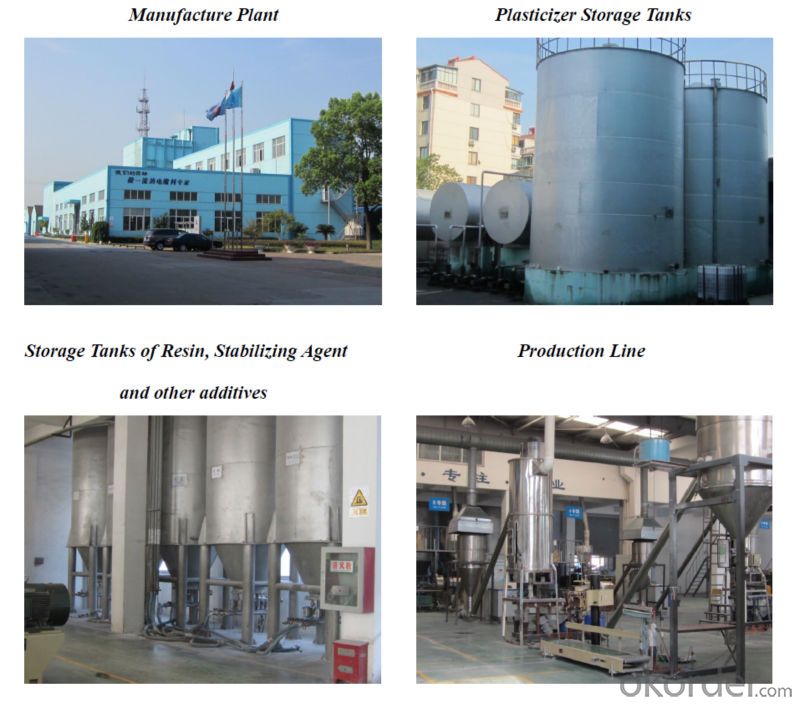

6. Company

- Q:How many kinds of raw materials are there for blowing plastic bottles?

- Plastic bottles are made of polyethylene or polypropylene and added a variety of organic solvents. Plastic bottles are widely used in polyester (PET), polyethylene (PE), polypropylene (PP) as raw material, add the corresponding organic solvent after high-temperature heating, the plastic mold by blow molding, extrusion blow or injection molding of plastic containers.

- Q:Application of CPE in plastics industry

- Resin type CPE in the product is also known as "A" material, elastic rubber type CPE has become B type material!Application: in the late 1990s, the domestic demand for high-performance flame-retardant rubber is increasing, especially the development of wire and cable industry and auto parts manufacturing industry, which has led to the consumption demand of rubber based CPE. Rubber based CPE is a kind of special synthetic rubber with good comprehensive properties, heat resistance, ozone aging and good flame retardancy.Mainly used in wire and cable (coal mine cable, UL and VDE standards such as the provisions of the wire), hydraulic hose, hose, adhesive tape, rubber sheet, PVC profiles, pipe modification, magnetic materials, ABS modification, and so on.

- Q:What plastic material has great impact resistance?

- Plastic raw materials Linai the maximum impact strength is MC nylon, the impact strength was > 500 kg. L cm / cm, nylon 11 cm / cm - 380 kg. The impact strength of polycarbonate, poly (phenol oxide), F-46, poly phenol, Yaan, low pressure polyethylene, polypropylene and nylon 1010 unreinforced is continuous".

- Q:What are the criteria for the classification of plastic materials at injection molding and extrusion?

- The new plastic materials, manufacturers have set by type of good applicability, according to the model can be used, but not to say that the plastic extrusion grade no injection molding, injection molding grade plastic extrusion processing can not, some engineers to use the material properties, will use the technological method for solving extrusion or injection molding grade between the influence.

- Q:Pollution in the production of plastic raw materials from petroleum production

- Manufacturing process of resin is the number of small molecular materials (high molecular compound monomer, alkane, olefin, could also have liquid such as gasoline and diesel decomposed) by polymerization together into a polymer compound. The polymerization can be divided into polymerization and polycondensation according to the composition of monomer and the change of result.The reaction of monomer addition and polymerization is called polymerization. Condensation polymerization is the process of reaction, in addition to forming high polymer, but also produce water, alcohol, ammonia and other low molecular by-products. The composition of the polymer is different from that of the raw monomer. After polymerization, the polymers with large molecular weight can be obtained. Synthetic resins are polymers of high molecular weight. Resins can be divided into two categories according to their properties after heating: one is called thermoplastic resin, and the other is thermosetting resin. Thermoplastic resin after heating can soften, flow, repeatedly plasticization and molding, such as polyethylene, polypropylene, polystyrene, polyvinyl chloride, polyamide; thermosetting resin is soluble and fusible before processing, but in the heating, pressurizing and curing agent under the action can become insoluble and infusible, cannot be heated again softening products to curing, phenolic resin, urea formaldehyde resin, epoxy resin, unsaturated resin belongs to this kind of resin.

- Q:What are the raw materials for plastic products? Resin or oil?

- There is no definite classification of plastics at present. The general classification is as follows: 1.. According to the physical and chemical properties of plastics, thermoplastics can be repeatedly heated, softened and cooled to harden in a certain temperature range. Such as polyethylene plastic, PVC plastic.Thermosetting plastics: Plastics cured by heat or other conditions without melting into insoluble material. Such as phenolic plastics, epoxy plastics and so on

- Q:How to identify the proportion of nozzle material in plastic?

- This result has two conclusions: 1, with large ratio of feed back. 2, the molding process causes the plastic cracking phenomenon to be more serious. The following is a screenshot of the performance of the material. It is important to note that the same plastic has different data downstream of different test conditions, so it is necessary to refer to the test conditions on the physical chart.

- Q:Plastic raw materials, electroplating grade round face, electroplating grade, what is the concept?

- The so-called plastic raw material electroplating grade means that the particle of the plastic material is high in purity and high in polarity, and is easy to be evenly adhered to the metal particles before the plating.

- Q:What can recycled plastics do?

- Can replace some wooden products; can be used to make all kinds of plastic bags, barrels, pots, toys and other plastic products, living utensils. Recycled plastic granulator, plastic prospects, turn products (plastic particles) a wide, plastic enterprises demand, a medium-sized agricultural film factory, in need of more than 1000 tons of polyethylene particles, a medium-sized shoe factory in need of more than 2000 tons of PVC particles, smaller private enterprises, with particles in years more than 500 tons, so the plastic particles in a large gap, can not meet the demand, so the plastic manufacturers, sales of excellent, excellent benefits.

- Q:How to make plastic raw materials?

- oil refiningPetroleum crackingCracking is the process of breaking down hydrocarbons with relatively large molecular weight and high boiling point under certain conditions, which are relatively small molecular weight and low boiling point hydrocarbons.Cracking under catalysis, also known as catalytic cracking.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low Smoke Halogen Free Flame Retardant Polyolefin Jacket Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords