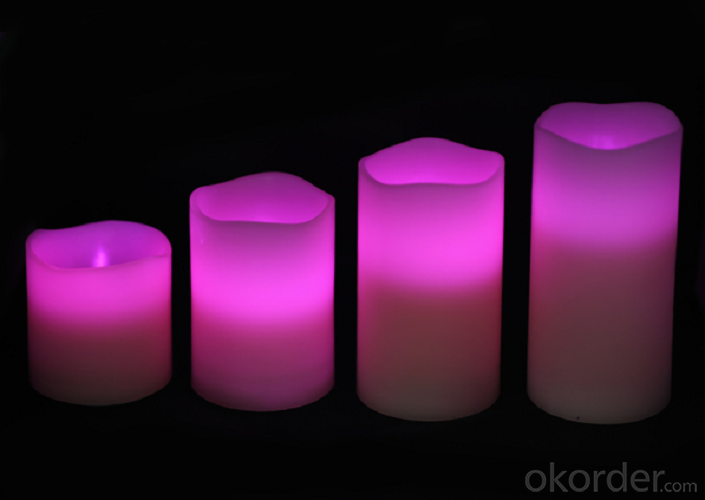

LED Candle LED Decoration light

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Remote Control Flameless Moving Wick Led Candle

1.Real moving flame

2.Natural,non-toxic no smoking and non-polluting,

3.High quality and competitve price

4.Fast delivery time

Directions for use

Candles are 3 inch diameter and use 3 AAA batteries, not included.

All Candles Use the Same Remote

All Sizes Work Together

Remote Has 17 Foot Range

Application

1.Christmas gift ,Valentine gift, Gift presenting, valentine craft

2.Home, party, bar, office decoration,

3.Birthday, valentine, wedding, christmas decoration

4.Business gift

Picture

- Q:Advantages and disadvantages of LED light source

- Long service lifeThe use of LED under normal circumstances, the light can be reduced to 70% of the nominal life is 100 thousand hours, reducing the frequency of replacement and other maintenance work.

- Q:Why does the LEd light source flash in a flash and feel unstable? Where is the problem?

- LED lights are flashing, that is, the circuit board (small bulb and into the luminous plate) there is a problem, the computer went to change, and told him that the display circuit board for Kazakhstan, five hundred or six hundred yuan, not expensive. TV is simply not, and LED light problems, we can imagine that this TV on the human body radiation hazards are serious. Don't understand, ask me again...

- Q:TracePro simulation, how to establish LED light source is accurate

- General manufacturers will have the corresponding LED light source data, import directly on it.

- Q:LED light source: why is the lower the power, the higher the light efficiency?

- LED light source is a semiconductor device. When converting electric energy into light, it also generates heat, increasing the temperature of LED chips. The higher the temperature, the weaker the ability to convert light into light.

- Q:Double Bay light specifications? The light source power is big?

- With the best domestic commercial lighting NVC as an example I give some examples to help youSmall hole size: 105MM*210MM halogen lamp power can replace 25W~50W or LED light source in a head (the brightness of LED a little bit worse, 3~5W power in general a head)Medium size: aperture size 168MM*345MM QR111 aluminum cup light source power is generally 50WMetal halide light source: hole size 157MM*345MM, metal halide light source is the best brightness, power is generally 70W, but the brightness is a few times the halogen light sourceThe size of holes for examples of NVC products in a random,

- Q:What are the main differences between LED electric light source, LED surface light source and LED line light source?

- The literal difference is that the LED point light refers to one of the len light sources emitting light from one of them.

- Q:Why use LED light source for lighting source line array CCD image sensor measuring circuit, pulse frequency to drive by linear CCD line integer times?

- The light source to ensure that at least one line in the pixel readout time is stable, so the driving frequency must be an integer multiple of CCD readout frequency or frequency.

- Q:What's the difference between a LED backlight and a surface light source?

- Source: generally refers to the OLED surface light source or that directly is LED on the back, the front surface of the hood. The structure of fog

- Q:What is the difference between a LED UV light source and a traditional UV lamp?

- The difference between LEDUV light source and traditional UV lamp is: 1. Long life: the service life is more than 10 times of the traditional mercury lamp type curing machine. 2, is a cold light source, no heat radiation, the surface temperature of the product is low, to solve the optical communication and liquid crystal production in the long-term heat damage problems. 3, small calorific value, can solve mercury lamp, inkjet equipment, calorific value, staff difficult to endure. 4, instant light, without preheating, immediately reach 100% power UV output. 5, the service life is not affected by the number of opening and closing. 6, high energy, light output stability, irradiation uniformity, good effect, improve production efficiency. 7, custom irradiation areas can be customized, ranging in length from 7mm to 1000mm. 8, without mercury or ozone, is a safer and more environmentally friendly alternative to conventional light sources. 9, low consumption, power consumption is only 10% of the traditional mercury lamp curing machine

- Q:LED screen backlight, straight down and side entry, what's the difference? The forms of light?

- The side light type LED backlight application in large size LCD, light weight and cost will increase with the increase in size, and the brightness and uniformity is not ideal, and side light type LED backlight LCD TV because of the light guide plate can not realize the regional dynamic LCD TV control, can only achieve a simple one-dimensional dimming, and direct type LED backlight performance is relatively good, it can achieve the dynamic control of LCD tv. Direct type backlight source process is relatively simple, does not need the light guide plate, the light source is (LED chip array) and PCB in the backlight bottom, light emitted from the LED, through the reflection sheet at the bottom, then through the diffusion plate, the surface brightness enhancement film evenly emitting. The thickness of the backlight is mainly determined by the height of the cavity between the reflecting film and the scattering plate. In theory, the greater the height of the cavity, the better the uniformity of light emitted from the scatter plate in the light of the installation requirements and brightness.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LED Candle LED Decoration light

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords