Insulating Refractory Bricks High-Alumina Brick for Furnace Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

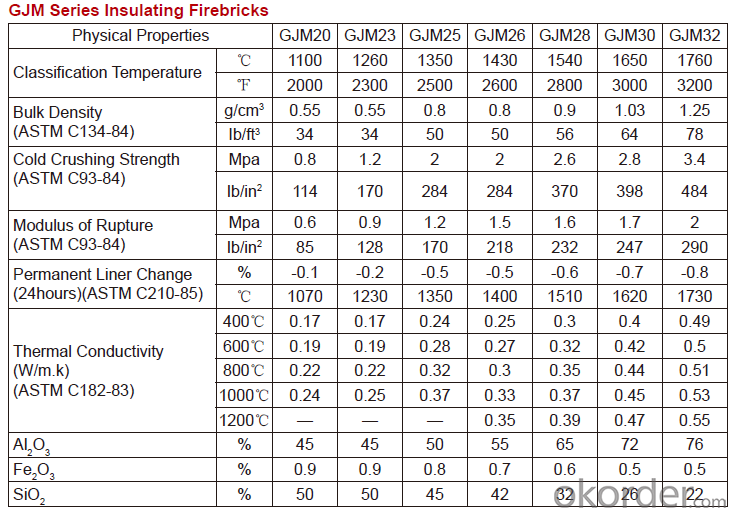

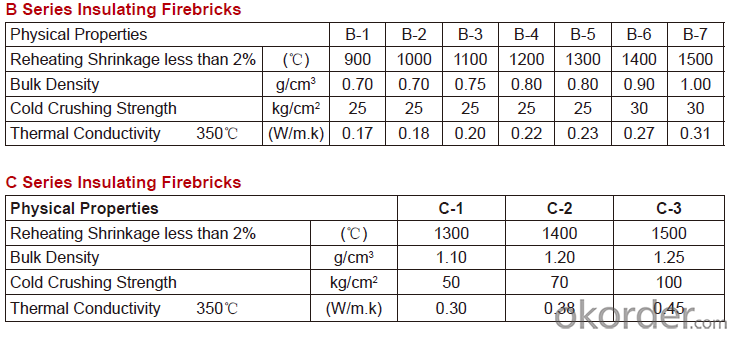

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:Can insulating fire bricks be used in the construction of lime recovery kilns?

- Yes, insulating fire bricks can be used in the construction of lime recovery kilns. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for such applications. They help to conserve energy and maintain the desired temperature within the kiln, enhancing the efficiency of the lime recovery process.

- Q:What is the water absorption of insulating fire bricks?

- The water absorption of insulating fire bricks is typically low, ranging from 5% to 10%.

- Q:Insulation brick should pay attention to external walls?

- Before the tile is adhered, the water spraying device is applied to spray the wet water on the adhered base layer so as not to flow better.

- Q:Are insulating fire bricks resistant to weathering or aging?

- Yes, insulating fire bricks are highly resistant to weathering and aging. These bricks are specifically designed to withstand extreme temperatures and harsh environmental conditions. They are made from high-quality refractory materials, such as alumina, silica, and other additives, which provide excellent thermal insulation properties and high resistance to corrosion and erosion. The manufacturing process of insulating fire bricks involves carefully selected raw materials and precise control of firing temperatures, resulting in a dense and uniform structure. This structure prevents the penetration of moisture and other weathering agents, ensuring prolonged durability and resistance to aging. Furthermore, insulating fire bricks are also resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or crumbling. This characteristic further enhances their ability to endure adverse weather conditions. Overall, insulating fire bricks have proven to be highly reliable in various applications where exposure to weathering elements is a concern. They are widely used in industries such as steel, ceramic, glass, and cement manufacturing, as well as in high-temperature applications like kilns, furnaces, and chimneys.

- Q:Are insulating fire bricks easy to clean?

- Insulating fire bricks are relatively easy to clean compared to other types of bricks. Due to their porous nature, they do not accumulate as much dirt or debris as regular bricks. Cleaning insulating fire bricks typically involves using a soft brush or a vacuum cleaner to remove loose dust or soot. For more stubborn stains or residues, a mild detergent solution can be applied, followed by a gentle scrubbing and rinsing. However, it is essential to avoid using harsh chemicals or abrasive materials that could damage the surface of the bricks. Overall, with proper care and maintenance, insulating fire bricks can be cleaned relatively easily.

- Q:Can insulating fire bricks be used in combination with other insulation materials?

- Yes, insulating fire bricks can be used in combination with other insulation materials. They can be used as a primary insulation layer or in conjunction with other materials such as ceramic fiber insulation or refractory coatings to enhance insulation efficiency and achieve higher temperature resistance. This combination of insulation materials can provide better thermal insulation properties and increased energy efficiency in various applications such as furnaces, kilns, and high-temperature industrial processes.

- Q:Are insulating fire bricks resistant to acids?

- Yes, insulating fire bricks are generally resistant to acids. They are made from materials that can withstand high temperatures and are chemically stable, making them suitable for applications where acid resistance is required.

- Q:Can insulating fire bricks be used in the construction of hot blast stoves?

- Indeed, it is possible to utilize insulating fire bricks in the fabrication of hot blast stoves. These bricks are specifically engineered to possess a low thermal conductivity, rendering them highly efficient in diminishing heat dissipation. In order to ensure optimal functionality, hot blast stoves necessitate the maintenance of elevated temperatures, a goal that can be accomplished through the utilization of insulating fire bricks, which effectively restrict heat transfer to the stove's external surface. Furthermore, these bricks exhibit commendable insulation properties, enabling energy conservation and enhancing the overall efficiency of the stove. Moreover, it is worth noting that insulating fire bricks are resistant to thermal shock, a crucial attribute in hot blast stove applications where frequent temperature fluctuations are common.

- Q:Are insulating fire bricks suitable for use in glass furnaces?

- Indeed, glass furnaces can benefit from the use of insulating fire bricks. The purpose of these bricks is to possess a low thermal conductivity, thereby effectively insulating the soaring temperatures within the furnace. By minimizing heat loss, these bricks ensure a steady temperature is maintained inside the furnace, a vital factor in the glass-making process. Moreover, insulating fire bricks are capable of enduring the intense temperatures and thermal shocks typically experienced in glass furnaces. Additionally, their lightweight nature facilitates simple installation and maintenance procedures. In conclusion, insulating fire bricks prove to be a dependable and pragmatic option for utilization in glass furnaces.

- Q:Do insulating fire bricks expand and contract with temperature changes?

- Insulating fire bricks do indeed undergo expansion and contraction in response to temperature variations. Similar to all other materials, exposure to heat causes these bricks to expand, whereas cooling leads to their contraction. This expansion and contraction phenomenon arises from the material's thermal expansion coefficient, which dictates the degree of expansion or contraction in relation to temperature changes. It is crucial to acknowledge this characteristic when utilizing insulating fire bricks in situations that involve anticipated temperature fluctuations. Neglecting to account for the expansion and contraction may result in structural harm or the formation of cracks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulating Refractory Bricks High-Alumina Brick for Furnace Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords