All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

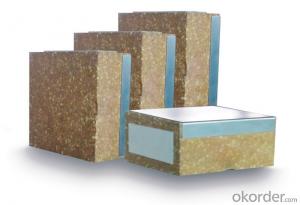

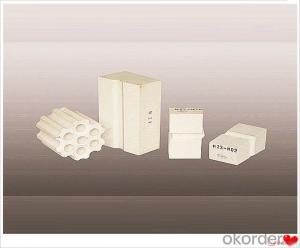

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do refractory bricks contribute to reducing maintenance costs in industrial processes?

Refractory bricks contribute to reducing maintenance costs in industrial processes by providing excellent resistance to high temperatures, corrosion, and mechanical abrasion. Their ability to withstand extreme conditions prolongs the lifespan of equipment and prevents frequent replacements or repairs. Additionally, refractory bricks have low thermal conductivity, which helps to conserve energy and reduce heat loss, resulting in lower operational costs.

How do refractory bricks resist slag erosion?

Refractory bricks resist slag erosion primarily due to their high melting point and chemical composition, which enables them to withstand the corrosive effects of molten slag. Additionally, their dense structure and low porosity limit the penetration of slag into the brick, thereby minimizing erosion.

How are damaged refractory bricks replaced?

Damaged refractory bricks are typically replaced by carefully removing the damaged bricks from the lining, ensuring no further damage is done to the surrounding bricks. New refractory bricks are then installed, using appropriate refractory mortar, to ensure a secure and tight fit within the lining. The process requires skilled workers who are knowledgeable in refractory brick installation techniques.

What are the different shapes and sizes of refractory bricks?

Refractory bricks come in various shapes and sizes depending on the specific application. Common shapes include straight, wedge, arch, and special shapes such as key bricks. Sizes can range from standard dimensions to customized sizes tailored to fit specific requirements.

Are refractory bricks resistant to acids?

Yes, refractory bricks are generally resistant to acids. They are made from materials that have a high melting point and are chemically inert, which makes them highly resistant to corrosion and damage caused by acids.

Wholesale Refractory Bricks from supplier in Botswana

Whether you require Refractory Bricks for industrial furnaces, kilns, or any other high-temperature applications, we can cater to your specific requirements. Our team of experts is well-versed in the technical specifications and performance characteristics of different types of Refractory Bricks, ensuring that we can provide you with the most suitable product for your project.

In addition to supplying Refractory Bricks, we also offer comprehensive sales and technical support services. Our dedicated sales team is available to assist you with product selection, provide competitive quotations, and ensure efficient delivery to your location in Botswana. We understand the importance of timely delivery and strive to meet your project deadlines.

Furthermore, our technical support services are designed to assist you throughout the entire project lifecycle. From initial consultation and design to installation and maintenance, our team of experienced professionals is ready to provide expert advice and guidance. We can help you optimize your refractory system, enhance performance, and ensure the longevity of your equipment.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This allows us to offer competitive pricing and reliable procurement services for Refractory Bricks in Botswana. You can trust in our commitment to quality and our ability to meet your project needs.

Contact us today to discuss your requirements and discover how we can assist you with your Refractory Bricks needs in Botswana. We look forward to partnering with you and contributing to the success of your project.

In addition to supplying Refractory Bricks, we also offer comprehensive sales and technical support services. Our dedicated sales team is available to assist you with product selection, provide competitive quotations, and ensure efficient delivery to your location in Botswana. We understand the importance of timely delivery and strive to meet your project deadlines.

Furthermore, our technical support services are designed to assist you throughout the entire project lifecycle. From initial consultation and design to installation and maintenance, our team of experienced professionals is ready to provide expert advice and guidance. We can help you optimize your refractory system, enhance performance, and ensure the longevity of your equipment.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This allows us to offer competitive pricing and reliable procurement services for Refractory Bricks in Botswana. You can trust in our commitment to quality and our ability to meet your project needs.

Contact us today to discuss your requirements and discover how we can assist you with your Refractory Bricks needs in Botswana. We look forward to partnering with you and contributing to the success of your project.

Hot Search

- Monolithic Refractories in Eritrea

- Ceramic Fiber Products in Lesotho

- Refractory Bricks in Albania

- Raw Materials For Refractory in Ecuador

- Refractory Bricks in Bulgaria

- Raw Materials For Refractory in Chad

- Refractory Bricks in Syria

- Monolithic Refractories in Denmark

- Raw Materials For Refractory in Samoa

- Raw Materials For Refractory in Poland