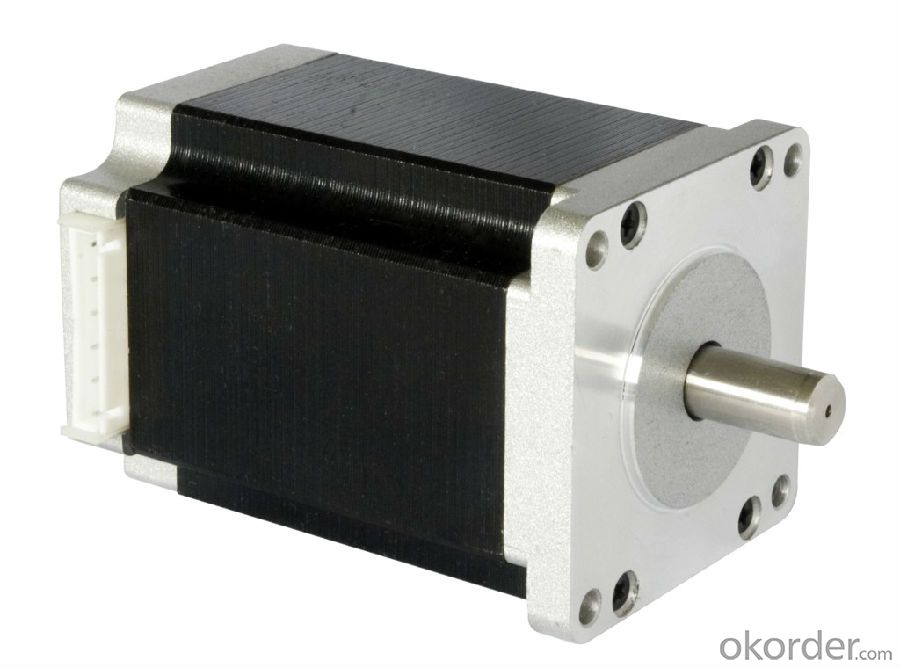

Hybrid Stepper Servo Motor Hs421 (42mm, 2Phase)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 2500 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Hybrid Stepper Servo Motor Hs421 (42mm, 2Phase)

Product Details

Basic Info.

Model NO.:HS421(1.8degree )42mm-2 Phase

Excitation Mode:HB-Hybrid

Type:Magnetic-Electric

Size:42mm

Speed:0-3000rpm

Resistance:100min 500VDC

Tem.:0-55

Export Markets:Global

Additional Info.

Trademark:I. CH

Standard:CE, RoHS, nqa

Origin:Nanjing China

Production Capacity:50, 000PCS/Year

Product Description

I.CH Motion Hybrid Stepper Servo Motor HS421

General Specifications

Speed:0-3000RPM

Insulation Resistance:100MIN,500VDC

Ambient Temperature:(0-55ºC

Encoder lines:2500/1000

| Electrical Specification | ||||||||

| Series Model | Rated Voltage (V) | L (mm) | Phase Current (A) | Phase Resistance (Ω) | Phase Inductance(mH) | Holding Torque (N.cm) | Moment of Inertia (g.cm2) | Motor Weight ( g) |

| HS421-05013A | 4.16 | 51 | 1.3 | 3.2 | 5.5 | 50 | 77 | 530 |

| HS421-05023A | 2.3 | 51 | 2.3 | 1.0 | 1.9 | 50 | 77 | 530 |

| HS421-05613A | 4.94 | 67 | 1.3 | 3.8 | 8.5 | 56 | 115 | 670 |

| HS421-07023A | 3.22 | 67 | 2.3 | 1.4 | 3.1 | 70 | 115 | 670 |

- Q:Is the torque characteristic characteristic of the step motor? Does the servo motor have a moment characteristic curve?

- The word "moment frequency" is not very accurate, so it's better to turn the torque, which means the torque changes as the speed changes Usually under rated speed servo motor, can output the continuous rated torque (note can be, how much actual output associated with working state), above the rated speed, can according to the constant power output (can be, the actual output power associated with state, such as your load bearing is small, the natural power is small)

- Q:12V step motor is driven by ULN2003. How does the voltage of 12V work?

- For the 12V voltage that drives the power supply, it is generally direct current, and the 12V dc power box can be selected. Power doesn't have to be too big!

- Q:What is the difference between a servo motor and a step motor?

- AC servo motors can be fully utilized when used in the organization shown in the left. The system is run after the X axis is run, and then run the Y-axis. In this case, it is very convenient because it can output the END of the X axis. If the X axis has an abnormal stop, it may affect other organizations. But it is very convenient because it sends a warning signal to the abnormal condition. High speed, high torque The characteristic of stepping motor is to be able to output great torque in low speed domain, but the torque will gradually decrease in high speed. AC servo motor can achieve stable high torque even in high speed. Therefore, it is suitable to use AC servo motor according to the long stroke.

- Q:What is the control of the frequency converter

- Stepper motor control points several commonly: small power stepping motor generally + power tube directly by single chip microcomputer control, but this does not control the whole step control, does not carry on the current closed loop control, control is simple, but the machine effect is poorer, generally in the home appliances or request is not high application occasions; If required by the step running effect of small probability is higher, can use special chip to control the general current closed-loop control is realized by using hybrid attenuation method, but the working voltage and working current is lower, the main drive, 42 small motor etc; For stepper motor general over 57 special drive control method was adopted to realize closed loop control of motor current, control methods including hysteresis comparison, attenuation, current analog hybrid PI, full digital control method. The best control method is to use DSP control all-digital stepper drive, can have inhibition of the stepper motor vibration and noise, and fever, improved the performance of the step

- Q:What is the connection between PLC and motor, including ordinary motors and stepper motors. What is their power supply?

- Most motors are not powered by a PLC. The PLC is only a function of operation judgment. It is generally necessary to control the contact device that is powered by the motor.

- Q:Why can't the stepping motor speed go up?

- Increase motor speed: drive current in the step motor drive. Precise positioning control: calculate the number of steps in the top machine or PLC.

- Q:What is step motor drive breakdown

- To understand the segmentation, it is important to understand the concept of a step Angle: it means that the control system each sends a pulse signal, which is the Angle of rotation. Motor factory is given a step away from the Angle of value, such as FY86EL402A type motor is given a value of 0.9 ° / 1.8 ° (half step work step 0.9 °, the whole work of 1.8 °), the interval Angle may call it the 'inherent interval Angle motor, it is not necessarily the real step away from the Angle of motor when the actual work. In short, a fine score is the actual step Angle at the run time of an electric motor. As can be seen from the table above, stepping motor drive to work in the state of 10 subdivision, the interval Angle for 'step motor inherent from the Angle of one over ten, that is to say: when a drive to work in step don't segment of the whole state, each hair a step pulse control system, 1.8 ° motor rotation; With subdivision driver work breakdown in 10 state, motor rotation only 0.18 °, which is the basic concept of subdivision. The more accurate description of the driver subdivision feature is the number of pulses that are run, and the number of pulses that are required to move each time a step into the motor run. FY86EL402A motor has 50 teeth, and if the run number is set to 160, then the step forward motor will need 50 times 160 = 8000 steps. Corresponding interval Angle is 360 ° present 8000 = 0.045 °. Note that if the running number is set to 30, the above table corresponds to a fine score of 7.5, not an integer.

- Q:How many kilograms does it take to get into the motor

- The dynamical parameters of the motor are generally torque, and the step of 57 is usually about two to three meters, and the weight of the drive depends on the structure and the way of the driver.

- Q:The difference between the servo motor and the step motor, and the usage

- The servo is generally used in high-power high-precision situation, the step power is small, the accuracy is poor, the cheap

- Q:The principle of permanent magnet step motor

- Just checked, the machine of the miniature printer USES 25 series of electric motor is permanent magnet, step in Angle 15 degrees. Apart, it's very rough. I used to focus on application and control, but I didn't notice. The 35 series that we use seem to be permanent magnet, too. The 42 series and the 58 series are mixed, and the two have been split several times. It seems that you want to design step motors. If I had to go that far, I wouldn't have figured it out. I'm just doing the application, and I'll show you a little bit more about how to control step motors. For your question, I suggest you look at the electrical engineering book, the electronic industry press. You're talking about eight magnetic claws in four phases, at least one pair per phase. The number of small teeth of a magnetic claw has to do with the step Angle. It seems that there is (at least some books in some books). Four phase eight beats is one way to run. This eight beats do not affect the design of the motor. In addition, based on my knowledge of the printer, most of the printer USES a hybrid step motor. The 42 series of motors that I use on this side are hybrid. It is as if permanent magnet motor, the step Angle is larger, not suitable for controlling the more delicate machine. I hope I can help you.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hybrid Stepper Servo Motor Hs421 (42mm, 2Phase)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 2500 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches