Hot-dip Aluzinc Steel Building Roof Walls in Best Price Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Aluzinc Steel Building Roof Walls in Best Price Best Quality

1. Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame, 4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

2.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

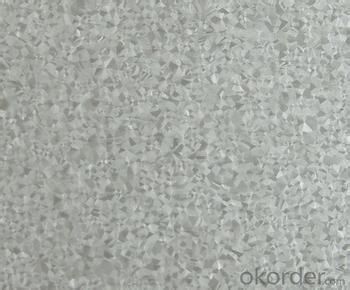

3.Hot-dip Aluzinc Steel Images

4.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION

HOT-DIP ALUZINC STEEL COILS | |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | 30g/ m2-185 g/ m2 |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S220GD+AZ S250GD+AZ S280GD+AZ S320GD+AZ S350GD+AZ S550GD+AZ | SGLC400 SGLC440 SGLC490 SGLC570 |

5.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Rotor Blade: Annual production capacity of 15,000 pieces, No.1 in China, Top3 worldwide

Light Weight Building Materials: Annual capacity of 1.65 billion square meters of gypsum board, No. 1 in the world.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2.What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

- Q:What are the latest advancements in monolithic refractories for the iron and steel industry?

- One of the latest advancements in monolithic refractories for the iron and steel industry is the development of high-performance castables with enhanced properties. These castables are designed to withstand the extreme temperatures and harsh conditions of iron and steel production processes. One major advancement is the use of advanced bonding systems that provide excellent strength and resistance to thermal shock. These bonding systems, such as nano-bonding technology, help improve the overall performance and durability of monolithic refractories. Another significant development is the introduction of low cement castables. These castables contain a reduced amount of cement, resulting in improved high-temperature strength and erosion resistance. This advancement is particularly beneficial for applications in the iron and steel industry where thermal cycling and mechanical stress are common. Additionally, there have been advancements in the composition of monolithic refractories. The use of advanced raw materials, such as high-quality aggregates and additives, has led to improved thermal conductivity, corrosion resistance, and thermal insulation properties. These developments allow for more efficient and sustainable iron and steel production processes. Furthermore, recent advancements have focused on the development of self-flow castables. These castables have excellent flowability, allowing for easy installation and maintenance of refractory linings. This advancement helps reduce installation time and costs while also ensuring improved lining performance. Overall, the latest advancements in monolithic refractories for the iron and steel industry have resulted in improved performance, durability, and efficiency. These advancements enable the industry to enhance its production processes, reduce downtime, and increase overall productivity.

- Q:How do monolithic refractories perform in aluminum holding furnace applications?

- Monolithic refractories perform exceptionally well in aluminum holding furnace applications due to their high thermal conductivity, excellent resistance to thermal shock, and superior mechanical strength. They can withstand the extreme temperatures and harsh chemical environments found in these furnaces, ensuring long-lasting and efficient operations. Additionally, monolithic refractories offer easy installation and maintenance, making them a preferred choice in aluminum holding furnace applications.

- Q:What are the key properties and characteristics of monolithic refractories?

- Monolithic refractories, renowned for their ability to be shaped or installed in a single piece without joints, are a type of refractory material. They find their utility in high-temperature applications where traditional brick or tile refractories may not suffice. One noteworthy attribute of monolithic refractories lies in their superior thermal stability. They can withstand extreme temperatures without significant expansion or contraction, making them an ideal choice for furnaces, kilns, and other heat-intensive environments. This quality ensures the maintenance of their structural integrity and grants long-lasting performance. Another significant characteristic of monolithic refractories is their high resistance to thermal shock. They can endure abrupt temperature changes without cracking or spalling, a crucial aspect when the refractory material is exposed to alternating hot and cold conditions. The resistance to thermal shock ensures the refractory lining's longevity, reducing the need for frequent repairs or replacements. Monolithic refractories also demonstrate commendable mechanical strength, enabling them to withstand the mechanical stresses and loads imposed on them during usage. They possess excellent load-bearing capacity, resisting abrasion, erosion, and impact, making them suitable for applications where the refractory material faces mechanical wear or impact. Moreover, monolithic refractories offer the advantage of easy installation and repair. Unlike traditional refractories that necessitate skilled labor and time-consuming bricklaying techniques, monolithic refractories can be cast, gunned, or sprayed into place. This effortless installation expedites turnaround times and minimizes downtime during repairs or maintenance. Lastly, monolithic refractories exhibit commendable chemical resistance to various corrosive agents, such as acids, alkalis, and molten metals. This property renders them suitable for use in industries where the refractory material encounters aggressive chemical environments, including the steel, petrochemical, and glass industries. In summary, monolithic refractories possess excellent thermal stability, high resistance to thermal shock, good mechanical strength, effortless installation and repair, and commendable chemical resistance. These properties establish them as the preferred choice in high-temperature applications where durability, reliability, and performance are of utmost importance.

- Q:What are the typical applications of monolithic refractories in the iron and steel industry?

- Monolithic refractories are widely used in various applications within the iron and steel industry. These refractories, which are made of a single material, offer several advantages such as ease of installation, resistance to thermal shock, and excellent resistance to chemical attacks. Here are some typical applications of monolithic refractories in the iron and steel industry: 1. Blast Furnace: Monolithic refractories are used in the lining of blast furnaces, where they are subjected to extreme temperatures and chemical reactions. They provide thermal insulation, prevent erosion, and resist the corrosive effects of molten iron and slag. 2. Ladles and Tundishes: Monolithic refractories are used to line ladles and tundishes, which are vessels used for transporting and transferring molten metal. These refractories offer good thermal insulation and resistance to erosion and chemical attack, ensuring the integrity of the vessels. 3. Steelmaking Converters: Monolithic refractories are utilized in converters, which are used in the steelmaking process to convert molten pig iron into steel. These refractories provide protection against the high temperatures and aggressive chemical environments encountered during the process. 4. Electric Arc Furnaces (EAF): Monolithic refractories are used to line the walls and roofs of EAFs, which are used to melt scrap steel for recycling. These refractories offer excellent thermal insulation, resistance to slag erosion, and thermal shock resistance, ensuring the longevity and efficiency of the furnace. 5. Continuous Casting: Monolithic refractories are employed in the continuous casting process, where molten steel is solidified into a continuous slab or billet. These refractories line the walls and floors of the casting molds, providing thermal insulation and resistance to chemical attack from the molten steel. 6. Reheating Furnaces: Monolithic refractories are used in reheating furnaces, which are used to heat steel billets or ingots prior to further processing. These refractories provide insulation, resist high temperatures, and ensure uniform heating of the metal. Overall, monolithic refractories play a crucial role in the iron and steel industry by providing reliable and durable linings in various applications. Their ability to withstand extreme temperatures, chemical attacks, and thermal shocks makes them indispensable for maintaining the integrity and efficiency of the production processes.

- Q:What are the recent developments in monolithic refractories for the iron and steel industry?

- Over the past few years, significant progress has been made in the field of monolithic refractories for the iron and steel industry. These refractories are vital in the production of iron and steel, as they provide insulation and withstand high temperatures in furnaces and other equipment. One major advancement is the development of advanced alumina-based castables. These castables offer exceptional thermal shock resistance, high strength, and excellent corrosion resistance, making them perfect for the iron and steel industry. They can endure extreme temperatures and mechanical stress, resulting in longer service life and less maintenance downtime. Another noteworthy development is the introduction of low-cement and ultra-low cement castables. Compared to traditional castables, these have reduced cement content, leading to improved refractory properties. They have higher hot strength, lower porosity, and increased resistance to slag and metal corrosion. This enhances productivity and efficiency in the iron and steel manufacturing processes. Moreover, insulating refractories have seen advancements in their usage. Insulating castables and bricks are now used to line ladles, tundishes, and other equipment, providing better insulation and energy efficiency. These materials help reduce heat loss and improve thermal efficiency, resulting in cost savings and reduced environmental impact. Additionally, there have been significant improvements in the installation techniques of monolithic refractories. Traditional brick lining methods require skilled labor and a longer installation time. However, the introduction of gunning and shotcreting techniques has made the process faster and more efficient. These techniques involve spraying refractory materials onto the lining surface, ensuring better adherence and reducing the risk of lining failure. Overall, recent developments in monolithic refractories for the iron and steel industry have focused on enhancing thermal shock resistance, corrosion resistance, insulation properties, and installation techniques. These advancements have led to increased efficiency, reduced downtime, and improved productivity in the iron and steel manufacturing processes.

- Q:How do monolithic refractories improve the lining of converters and refining vessels?

- Improving the lining of converters and refining vessels is a crucial role played by monolithic refractories in several ways. To begin with, these refractories offer exceptional thermal insulation properties, which effectively maintain the desired temperature within the converters and refining vessels. This is particularly important as the metallurgical processes require high temperatures to be effective. Furthermore, the high chemical resistance of monolithic refractories is vital in the harsh conditions of converters and refining vessels. These vessels often come into contact with corrosive materials and aggressive slags, but the monolithic refractories prevent any deterioration or erosion of the lining caused by these substances. In addition, the mechanical strength and stability provided by monolithic refractories ensure that the lining remains intact even under high operational stresses. This is especially significant in converters and refining vessels where frequent mechanical movements and thermal expansions occur. Moreover, monolithic refractories offer easy installation and repair compared to traditional bricks, which require complex and time-consuming assembling. Monolithic refractories can be applied as a single mass, minimizing downtime during installation or repair. This results in time and cost savings for maintaining the lining of converters and refining vessels. Overall, the utilization of monolithic refractories significantly enhances the performance and longevity of converters and refining vessels. Their excellent thermal insulation, chemical resistance, mechanical strength, and ease of installation and repair guarantee efficient and reliable operation in metallurgical processes.

- Q:What are the main causes of monolithic refractory failure in the iron and steel industry?

- There are several main causes of monolithic refractory failure in the iron and steel industry. One of the primary causes is thermal cycling. The extreme temperatures experienced in iron and steel manufacturing processes, such as melting, casting, and heat treating, subject the refractory lining to significant thermal stress. This repeated expansion and contraction of the material can lead to cracking, spalling, or even complete disintegration of the refractory. Another common cause of failure is chemical attack. The iron and steel industry involves the use of various chemicals, including molten metal, slag, and gases, which can react with the refractory lining. This chemical interaction can cause erosion, corrosion, or chemical decomposition of the refractory material, leading to its failure over time. Mechanical stress is also a significant factor in monolithic refractory failure. The heavy machinery and equipment used in iron and steel production can generate vibrations, shocks, and impacts that can weaken or damage the refractory lining. Additionally, improper installation or design can result in mechanical stress concentration points, making the refractory more susceptible to failure. Furthermore, improper maintenance and operational practices can contribute to refractory failure. Inadequate cooling or heating procedures, improper drying and curing of the refractory, and insufficient cleaning and inspection can all impact the longevity and performance of the material. Lack of regular maintenance and timely repairs can exacerbate small issues, leading to more significant failures over time. Lastly, the choice of refractory material and its quality can play a significant role in failure. Selecting an inappropriate refractory for the specific application or using low-quality materials can result in premature failure. It is crucial to consider factors such as temperature range, chemical exposure, and mechanical stress when choosing the refractory lining to ensure its suitability and durability in the iron and steel industry. In summary, the main causes of monolithic refractory failure in the iron and steel industry are thermal cycling, chemical attack, mechanical stress, improper maintenance and operational practices, and the choice and quality of refractory material. Addressing these factors through proper installation, regular maintenance, and careful material selection can help mitigate refractory failures and improve the overall efficiency and productivity of iron and steel production processes.

- Q:What are the challenges in recycling and disposing of monolithic refractories?

- One challenge in recycling and disposing of monolithic refractories is the high temperature resistance and durability of these materials, which makes them difficult to break down and recycle. Additionally, the presence of various contaminants, such as metals and other impurities, can further complicate the recycling process. Proper disposal of monolithic refractories also poses challenges due to the potential environmental impact of disposing of these materials, as they may contain hazardous substances. Therefore, finding efficient and environmentally-friendly methods for recycling and disposing of monolithic refractories remains a challenge in the industry.

- Q:How do monolithic refractories withstand the alkali attacks in cement kiln applications?

- Due to their unique composition and structure, monolithic refractories are capable of withstanding alkali attacks in cement kiln applications. Unlike traditional brick refractories, these refractories are made from a single material, resulting in a more uniform and dense structure. When exposed to alkali attacks in cement kilns, monolithic refractories create a barrier against the corrosive alkali substances by forming a protective layer on the surface. This protective layer is formed through reactions between the alkali substances and the refractory material, leading to the development of a stable compound that resists further attacks. Additionally, monolithic refractories possess high chemical resistance, allowing them to endure the aggressive conditions inside cement kilns. Their low porosity design minimizes the infiltration of alkali substances into the refractory material, reducing the risk of alkali attacks and extending the lifespan of the refractory lining. Furthermore, monolithic refractories are frequently manufactured using materials with elevated melting points, such as alumina, silica, and magnesia. These materials exhibit exceptional thermal stability, enabling the refractories to withstand the high temperatures in cement kilns without significant deterioration. This thermal stability is crucial in preventing the formation of cracks and spalling, which could permit alkali penetration and subsequent harm to the refractory lining. In conclusion, monolithic refractories are specifically engineered to resist alkali attacks in cement kiln applications by forming a protective layer, possessing high chemical resistance, and demonstrating excellent thermal stability. These characteristics make them an ideal choice for lining cement kilns, ensuring long-term performance and durability.

- Q:What are the advantages of using insulating castables in the iron and steel industry?

- The advantages of using insulating castables in the iron and steel industry are numerous. Firstly, insulating castables have excellent thermal insulation properties, which help to reduce heat loss during the manufacturing process. This leads to increased energy efficiency and cost savings for the industry. Additionally, insulating castables have a low thermal conductivity, meaning they can withstand high temperatures without transferring excessive heat. This is crucial in the iron and steel industry, where temperatures can reach extremely high levels. By using insulating castables, the industry can ensure the longevity and durability of its equipment and structures. Furthermore, insulating castables have good resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is particularly beneficial in the iron and steel industry, where the heating and cooling processes are frequent and intense. Lastly, insulating castables have a low density, making them lightweight and easier to handle and install. This not only saves time and effort during installation but also reduces the structural load on equipment and structures. Overall, the use of insulating castables in the iron and steel industry offers advantages such as improved energy efficiency, enhanced durability, resistance to thermal shock, and ease of installation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-dip Aluzinc Steel Building Roof Walls in Best Price Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords