High Temperature Ladle Sliding Gate Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

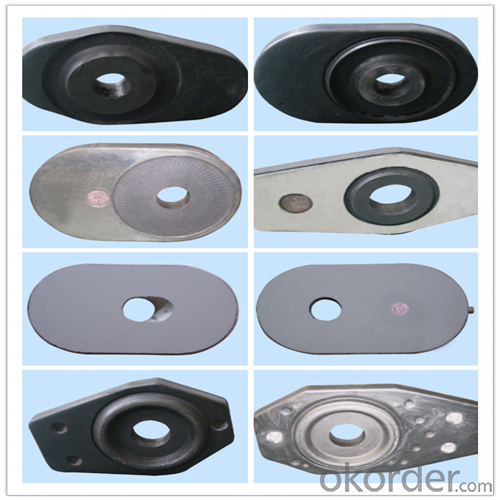

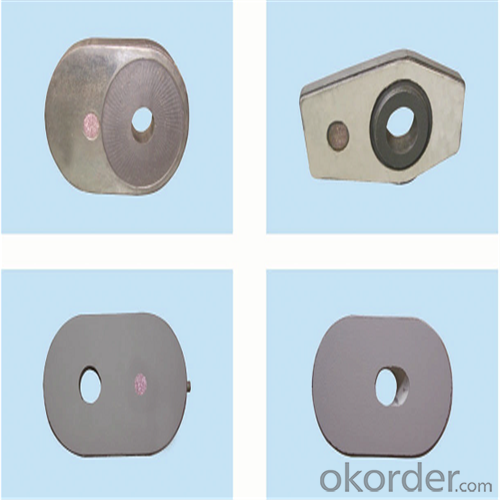

Quick Details for High Performance Refractory Ladle Slide Gate

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

General Chemical Analysis for refractory ladle slide gate :

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

Using the raw materials of tabular alumina, zirconia-corundum, carbon and other high-grade additives, after sintering to obtain characteristics of oxidation resistance, scour strength, erosion resistance, thermal shock resistance, shape stable and long service life, made our products the preferred materials for the large and medium-sized steel ladle, refining ladle, series of alloy steel ladle, and tundish. Our high performance sintering sliding gates include alumina carbon , Al2O3-ZrO2-C, etc, can meet the needs of different steel grade.

Other Products

About us

Sample is on your request.

Welcome to visit our factory~

- Q:What are the latest advancements in monolithic refractories for the iron and steel industry?

- One of the latest advancements in monolithic refractories for the iron and steel industry is the development of high-performance castables with enhanced properties. These castables are designed to withstand the extreme temperatures and harsh conditions of iron and steel production processes. One major advancement is the use of advanced bonding systems that provide excellent strength and resistance to thermal shock. These bonding systems, such as nano-bonding technology, help improve the overall performance and durability of monolithic refractories. Another significant development is the introduction of low cement castables. These castables contain a reduced amount of cement, resulting in improved high-temperature strength and erosion resistance. This advancement is particularly beneficial for applications in the iron and steel industry where thermal cycling and mechanical stress are common. Additionally, there have been advancements in the composition of monolithic refractories. The use of advanced raw materials, such as high-quality aggregates and additives, has led to improved thermal conductivity, corrosion resistance, and thermal insulation properties. These developments allow for more efficient and sustainable iron and steel production processes. Furthermore, recent advancements have focused on the development of self-flow castables. These castables have excellent flowability, allowing for easy installation and maintenance of refractory linings. This advancement helps reduce installation time and costs while also ensuring improved lining performance. Overall, the latest advancements in monolithic refractories for the iron and steel industry have resulted in improved performance, durability, and efficiency. These advancements enable the industry to enhance its production processes, reduce downtime, and increase overall productivity.

- Q:How do monolithic refractories improve the thermal efficiency of iron and steel furnaces?

- Monolithic refractories play a crucial role in improving the thermal efficiency of iron and steel furnaces. These refractories are essentially a single, solid mass that is used to line the furnaces and provide insulation and protection against the extreme temperatures generated during the metal production process. One way in which monolithic refractories enhance thermal efficiency is by reducing heat loss. These materials have low thermal conductivity, meaning they are poor conductors of heat. By lining the furnace with monolithic refractories, the heat generated inside the furnace is effectively contained within the chamber, minimizing heat loss to the surrounding environment. This allows for more efficient use of energy, as less heat is wasted and more of it is utilized for the intended purpose of heating and melting the metal. Additionally, monolithic refractories also contribute to the overall efficiency of the iron and steel furnaces by providing a high level of heat resistance. The extreme temperatures reached inside these furnaces can easily damage or deteriorate conventional refractory materials. However, monolithic refractories are designed to withstand these harsh conditions, maintaining their integrity and performance over extended periods. This durability ensures that the lining remains intact, preventing any potential leakage of heat and ensuring that the furnace operates at maximum efficiency. Furthermore, monolithic refractories offer flexibility in their installation process. They can be easily shaped and molded to fit the intricate designs and contours of the furnace, creating a seamless and continuous lining. This eliminates any gaps or weak points that could allow heat to escape or cold air to enter, further enhancing the thermal efficiency of the furnace. Overall, monolithic refractories significantly contribute to the thermal efficiency of iron and steel furnaces by reducing heat loss, providing high heat resistance, and ensuring a tight and continuous lining. By optimizing heat utilization and minimizing energy wastage, these refractories play a vital role in improving the productivity and sustainability of the iron and steel industry.

- Q:How do monolithic refractories improve the quality and consistency of iron and steel products?

- The use of monolithic refractories is essential for enhancing the quality and consistency of iron and steel products. These refractories, which are not shaped and can be easily molded and installed, offer several advantages over traditional brick refractories. To begin with, monolithic refractories provide superior thermal insulation properties, which effectively manage heat during the production process. By maintaining consistent and controlled temperatures, these refractories prevent thermal shocks and minimize thermal gradients, resulting in reduced cracking and distortion in the final products. As a result, the dimensional stability and overall quality of the products are improved. Additionally, monolithic refractories exhibit excellent resistance to thermal spalling and erosion. They can withstand high temperatures, chemical attacks, and mechanical stress, protecting the lining of furnaces and vessels used in iron and steel production. This resistance enhances the durability and reliability of refractory linings, preventing premature failure and extending the lifespan of the equipment. Another advantage of monolithic refractories is their ability to create a seamless lining. Unlike brick refractories, which have joints and gaps that can cause heat loss and uneven distribution, monolithic refractories form a continuous lining with no weak points. This ensures uniform heat distribution and minimizes the risk of hotspots or cold spots, resulting in consistent and reliable iron and steel products. Moreover, monolithic refractories offer flexibility in design and installation. They can be customized to fit various shapes and sizes, allowing for better furnace design optimization. This flexibility enables efficient use of space, improved heat transfer, and reduced energy consumption, all of which contribute to the overall quality and consistency of the final iron and steel products. In conclusion, monolithic refractories enhance the quality and consistency of iron and steel products by providing superior thermal insulation, resistance to thermal spalling and erosion, seamless linings, and flexibility in design and installation. These refractories improve the efficiency and reliability of the production process, resulting in higher-quality final products that meet the industry's stringent standards.

- Q:How do monolithic refractories withstand high temperatures and thermal shocks?

- Monolithic refractories are able to withstand high temperatures and thermal shocks due to their unique composition and design. These refractories are made from a single piece or structure, hence the term "monolithic". This structural integrity allows them to resist the extreme heat and sudden temperature changes experienced in high-temperature applications. One key factor that enables monolithic refractories to withstand high temperatures is the use of high-quality raw materials. These materials are carefully selected for their ability to withstand heat and thermal stress. Common components include silica, alumina, magnesia, and other refractory minerals with high melting points. Additionally, the manufacturing process plays a crucial role in enhancing the thermal resistance of monolithic refractories. The raw materials are mixed with binders, such as clay or cement, to form a homogenous mixture. This mixture is then shaped and installed in its final position, either by pouring or gunning, depending on the application. The binder ensures that the refractory maintains its shape and integrity during thermal cycling. Furthermore, monolithic refractories possess excellent thermal conductivity and low thermal expansion properties. This means that they can efficiently transfer and dissipate heat, minimizing the risk of thermal stress and cracking. The low thermal expansion also reduces the likelihood of spalling or delamination, which is crucial for withstanding thermal shocks. Another factor contributing to the high-temperature resistance of monolithic refractories is their ability to form a protective layer or slag at the surface. This layer acts as a barrier, preventing the refractory from direct contact with corrosive materials or aggressive atmospheres. It helps to improve the refractory's longevity and resistance to thermal shocks. Overall, the combination of high-quality raw materials, careful manufacturing techniques, and beneficial thermal properties enables monolithic refractories to withstand high temperatures and thermal shocks. These refractories are widely used in various industries, including steel, cement, glass, and petrochemical, where they serve as reliable linings in furnaces, kilns, and other high-temperature equipment.

- Q:How do monolithic refractories withstand the thermal cycling in coke oven applications?

- Monolithic refractories are specifically designed to withstand the harsh conditions of thermal cycling in coke oven applications. Thermal cycling refers to the repetitive heating and cooling cycles that occur in these high-temperature environments. One of the key factors that enables monolithic refractories to withstand thermal cycling is their composition. They are typically made from a combination of different refractory materials, such as high-alumina, silica, and magnesia, which provide excellent thermal shock resistance. These materials have low thermal conductivity and high thermal expansion properties, allowing them to expand and contract without cracking or spalling under extreme temperature changes. Moreover, monolithic refractories have excellent bonding and adhesion properties, allowing them to form a strong and cohesive structure. This ensures that they can withstand the mechanical stresses caused by the thermal cycling process. Additionally, monolithic refractories can be installed in place through various techniques, such as gunning, casting, or ramming, which further enhances their resistance to thermal cycling. Furthermore, the presence of specialized additives and bonding agents in monolithic refractories improves their resistance to thermal cycling. These additives can enhance the refractory's ability to absorb thermal shock and minimize cracking, thus increasing its durability and longevity in coke oven applications. Overall, monolithic refractories' ability to withstand thermal cycling in coke oven applications can be attributed to their carefully formulated composition, strong bonding properties, and the incorporation of specialized additives. These characteristics make them highly reliable and suitable for the extreme temperature fluctuations experienced in coke oven operations.

- Q:How do monolithic refractories contribute to the efficiency of iron and steel production?

- Monolithic refractories play a critical role in improving the efficiency of iron and steel production processes. These refractories are renowned for their superior thermal properties, high resistance to mechanical stress, and outstanding resistance to chemical corrosion. One primary manner in which monolithic refractories enhance the efficiency of iron and steel production is by providing effective insulation. By lining furnaces and other high-temperature equipment, monolithic refractories prevent heat loss and ensure consistent maintenance of desired temperatures. This insulation helps reduce energy consumption by minimizing heat wastage, ultimately resulting in cost savings. Moreover, monolithic refractories offer exceptional resistance to thermal shock. In the iron and steel industry, frequent heating and cooling cycles are common, and conventional refractory materials may crack or fail under these conditions. However, monolithic refractories can endure rapid temperature fluctuations without failure, guaranteeing the longevity and reliability of the refractory lining. This resistance to thermal shock reduces downtime for repairs and maintenance, thereby increasing overall production efficiency. Furthermore, monolithic refractories exhibit significant resistance to chemical corrosion. In iron and steel production, various corrosive substances such as molten metal, slag, and gases are present. By utilizing monolithic refractories as lining materials, the underlying structures are protected from chemical attack, preventing erosion and prolonging the equipment's service life. This corrosion resistance reduces the need for frequent repairs or replacements, leading to cost savings and enhanced productivity. Additionally, monolithic refractories offer easy installation and repair. Unlike traditional refractories, which are often constructed brick by brick, monolithic refractories are applied as a single mass. This allows for faster installation and reduces the potential for weak points or joints that may compromise the overall efficiency of the refractory lining. Furthermore, when repairs or maintenance are necessary, monolithic refractories can be easily patched or replaced, minimizing downtime and ensuring seamless operation. To summarize, the use of monolithic refractories in iron and steel production contributes to increased efficiency in multiple ways. Their outstanding thermal insulation properties reduce energy consumption, while their resistance to thermal shock and chemical corrosion ensures reliable and long-lasting refractory linings. Additionally, their easy installation and repair capabilities further enhance productivity. Overall, monolithic refractories are an indispensable component in improving the efficiency and sustainability of iron and steel production processes.

- Q:What are the considerations for repairing and patching monolithic refractories?

- When it comes to repairing and patching monolithic refractories, there are several important considerations that need to be taken into account. Firstly, it is crucial to carefully assess the extent and severity of the damage or deterioration. This will help determine the appropriate repair method and materials needed. Small cracks or minor damage may only require a simple patching or sealing, while larger or more severe damage might necessitate a complete replacement or a more extensive repair process. Secondly, the type of monolithic refractory material being used is an important factor to consider. Different types of monolithic refractories have varying properties and characteristics, such as thermal conductivity, chemical resistance, and mechanical strength. Therefore, it is crucial to choose a repair material that is compatible with the existing refractory material to ensure proper bonding and performance. Another consideration is the operating conditions and environment in which the monolithic refractory is exposed. Factors such as temperature, pressure, chemical exposure, and abrasion can significantly impact the durability and longevity of the refractory material. Understanding these conditions will help in selecting the appropriate repair materials and techniques that can withstand and perform well under these specific conditions. Additionally, the repair process should be carried out by experienced personnel who are knowledgeable about refractory materials and their installation. Improper repairs can lead to further damage or reduced performance, so it is essential to have skilled professionals who can perform the repair work correctly. Lastly, regular inspection and maintenance of the monolithic refractories are essential to detect any potential damage or deterioration early on. Timely repairs and patching can prevent further deterioration and extend the service life of the refractory material. In summary, considerations for repairing and patching monolithic refractories involve assessing the extent of damage, selecting compatible repair materials, understanding the operating conditions, employing skilled personnel, and conducting regular inspections and maintenance. By taking these factors into account, one can ensure effective repairs and the continued performance of monolithic refractories.

- Q:What are the benefits of using monolithic refractories in the iron and steel industry?

- Monolithic refractories offer numerous benefits in the iron and steel industry. Firstly, they provide excellent thermal insulation, reducing heat loss and improving energy efficiency in furnaces and other equipment. Secondly, monolithic refractories have superior resistance to high temperatures, ensuring prolonged service life even under extreme conditions. Additionally, their flexibility allows for easy installation and repair, reducing downtime and maintenance costs. Moreover, monolithic refractories have enhanced chemical resistance, protecting against corrosive and reactive substances commonly found in iron and steel production. Overall, the use of monolithic refractories enhances productivity, extends equipment lifespan, and reduces operational costs in the iron and steel industry.

- Q:How do monolithic refractories improve the efficiency of ladle and tundish preheaters?

- Monolithic refractories play a crucial role in improving the efficiency of ladle and tundish preheaters through several key mechanisms. Firstly, monolithic refractories provide excellent thermal insulation properties. They have low thermal conductivity, which means they are effective in preventing heat loss from the preheaters. By minimizing heat loss, monolithic refractories ensure that the majority of the heat generated by the preheater is utilized for preheating the ladle or tundish. This results in reduced energy consumption and improved efficiency of the preheating process. Secondly, monolithic refractories offer high thermal shock resistance. Ladle and tundish preheaters are subjected to rapid and extreme temperature changes during operation. The ability of monolithic refractories to withstand these thermal shocks ensures their long-lasting performance, minimizing the need for frequent repairs or replacements. This not only enhances the efficiency of the preheaters but also reduces downtime and maintenance costs. Furthermore, monolithic refractories exhibit excellent mechanical strength and abrasion resistance. The ladle and tundish preheaters experience constant wear and tear due to the movement of ladles or tundishes, and the abrasive nature of the materials being processed. The use of monolithic refractories prevents erosion and damage to the preheaters, ensuring their longevity and optimal functioning. This, in turn, improves the overall efficiency of ladle and tundish preheaters by reducing downtime and maintenance requirements. Lastly, monolithic refractories offer design flexibility. They can be customized and shaped according to the specific requirements of the ladle or tundish preheaters. This allows for better fitting and insulation, maximizing heat transfer efficiency. The ability to tailor the refractory lining to the preheater's design also ensures uniform heating, minimizing temperature variations and improving overall operational efficiency. In summary, the use of monolithic refractories in ladle and tundish preheaters improves efficiency by providing superior thermal insulation, thermal shock resistance, mechanical strength, abrasion resistance, and design flexibility. These properties result in reduced heat loss, minimized downtime, enhanced durability, and optimized heat transfer, ultimately leading to improved efficiency of the preheating process.

- Q:What are the common failure mechanisms of monolithic refractories?

- Some common failure mechanisms of monolithic refractories include thermal shock, spalling, erosion, chemical attack, and mechanical stress. These factors can weaken the refractory material, causing it to crack, break, or deteriorate over time.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Temperature Ladle Sliding Gate Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords