All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

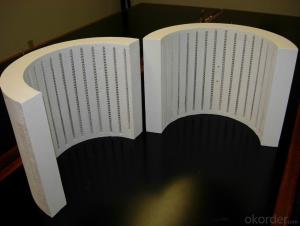

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do additives enhance the performance of refractory materials?

Additives enhance the performance of refractory materials by improving their mechanical strength, thermal shock resistance, and corrosion resistance. These additives can also promote better bonding between particles, increase density, reduce porosity, and enhance the overall stability and durability of the refractory material.

What are the refractory materials used in the ceramic and chemical industries?

Refractory materials commonly used in the ceramic and chemical industries include alumina, silica, zirconia, magnesia, and graphite.

How are refractory cements used in insulation linings?

Refractory cements are used in insulation linings as a high-temperature adhesive and sealing material. They are applied to bond refractory bricks or insulation materials together, creating a strong and durable lining that can withstand extreme heat conditions. Refractory cements also help fill any gaps or cracks, providing a tight and efficient insulation barrier.

How are refractory materials used in the petrochemical industry?

Refractory materials are used in the petrochemical industry to line furnaces, reactors, and other equipment that are exposed to high temperatures and corrosive environments. These materials help to protect the equipment from thermal shock, chemical attack, and wear and tear, ensuring their longevity and efficient operation.

Wholesale Refractory Materials from supplier in Maldives

We look forward to working with you and providing you with top-notch Refractory Materials and excellent customer service. Contact us today to discuss your specific needs and requirements.

Hot Search

- Monolithic Refractories in Lebanon

- Ceramic Fiber Products in Slovenia

- Refractory Bricks in Montenegro

- Raw Materials For Refractory in Bengal

- Monolithic Refractories in Fiji

- Refractory Bricks in Senegal

- Monolithic Refractories in Cambodia

- Refractory Bricks in Spain

- Ceramic Fiber Products in Andorra

- Refractory Bricks in Nauru