Grade AISI1045 Din1.1191 JIS s45c GB45 Hot Rolled Carbon Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Details of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Name | SAE1045 Carbon Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Grades Comparison

GB | ASTM | JIS | DIN | BS | NF |

45# | 1045 | S45C | C45 | IC45 08047 | C45 |

Chemical Composition

C | Si | Mn | Cr | P/S | Cr |

0.42-0.50 | 0.17-0.37 | 0.5-0.8 | ≤0.25 | ≤0.35 | 0.3-0.5 |

Sizes information

Sizes detalis | diameter | 16-320mm |

length | 3-12m(canbe customerized) | |

Sizes tolerance (max) | length | +/-100mm |

diameter | +/-2mm | |

Straightness | 3mm/m |

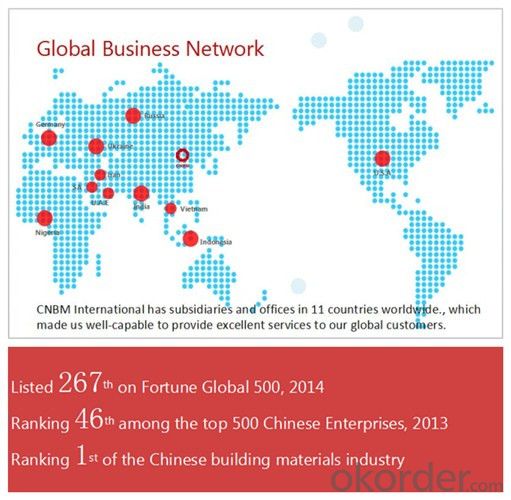

CNBM Introduction of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel contribute to the toughness of products?

- Special steel contributes to the toughness of products through its superior strength, durability, and resistance to wear and corrosion. This high-quality steel is specifically engineered to possess exceptional mechanical properties and enhanced toughness, making it ideal for demanding applications. Its ability to withstand extreme conditions, impacts, and heavy loads ensures that products made from special steel are long-lasting, reliable, and capable of enduring harsh environments.

- Q: How does special steel contribute to the automotive racing industry?

- The automotive racing industry heavily relies on special steel to ensure the high performance and safety of race cars. With its exceptional properties such as strength, durability, and heat resistance, special steel is the ideal choice for various applications in racing vehicles. One of the primary contributions of special steel to the automotive racing industry lies in its utilization in the construction of engine parts. Crankshafts, camshafts, connecting rods, and valves, which face extreme forces and temperatures during racing, benefit greatly from special steel alloys, particularly high-strength steels. These alloys are specifically engineered to withstand such demanding conditions, providing superior performance compared to conventional steel. As a result, race car engines can operate at higher speeds, generate more power, and endure intense racing conditions without compromising reliability. Moreover, special steel is extensively employed in the production of suspension systems and chassis components. Racing cars experience extreme loads and vibrations while cornering and maneuvering at high speeds. By incorporating high-strength steel into these critical components, the structural integrity of the vehicle is enhanced, leading to improved stability, handling, and overall performance. Aside from its performance advantages, special steel also significantly contributes to the safety of race cars. Safety is paramount in the racing industry, and the use of special steel in roll cages and crash structures provides enhanced protection for drivers in the event of accidents. Special steel alloys, such as boron steel, possess exceptional strength and energy absorption capabilities, thereby minimizing the risk of injuries during crashes. Furthermore, the lightweight nature of special steel allows for the reduction of the overall vehicle weight, resulting in improved fuel efficiency and better handling. Through the utilization of advanced steel materials and design techniques, race car manufacturers can strike a balance between strength and weight, optimizing performance while ensuring safety. In conclusion, special steel plays a vital role in the automotive racing industry by contributing to the performance, safety, and reliability of race cars. Its unique properties enable the development of high-performance engine parts, suspension systems, and chassis components, allowing race cars to withstand extreme conditions and achieve superior performance on the track. Additionally, special steel enhances the safety of race cars by providing robust crash protection, while also offering weight reduction benefits for improved fuel efficiency and handling.

- Q: Is special steel suitable for manufacturing cutting tools?

- Yes, special steel is suitable for manufacturing cutting tools. Special steel, also known as tool steel, is specifically designed to have high hardness, wear resistance, and toughness, making it ideal for cutting tool applications. It can retain sharpness for an extended period, withstand high temperatures, and provide excellent cutting performance, making it a preferred choice for manufacturing cutting tools such as drills, saw blades, and milling cutters.

- Q: What are the different types of precipitation-hardening steel?

- There are several different types of precipitation-hardening steel, including 17-4 PH, 15-5 PH, 13-8 PH, and 17-7 PH. These alloys are known for their ability to be strengthened through a precipitation hardening process, which involves a combination of heat treatment and aging. Each type of precipitation-hardening steel has its own unique composition and properties, making them suitable for various applications in industries such as aerospace, automotive, and medical.

- Q: How does special steel contribute to the renewable energy sector?

- Special steel plays a crucial role in the renewable energy sector by enabling the construction of highly efficient and durable renewable energy infrastructure. It is used in the manufacturing of wind turbine components, solar panels, and hydroelectric power systems, among others. Its exceptional strength, corrosion resistance, and ability to withstand extreme conditions make it ideal for withstanding harsh weather and environmental factors. Additionally, special steel helps optimize energy conversion and transmission, ultimately improving the overall efficiency and reliability of renewable energy systems.

- Q: How does special steel contribute to the aerospace material cost reduction?

- Special steel contributes to the aerospace material cost reduction by offering enhanced properties such as high strength, lightweight, and corrosion resistance. These qualities allow for the use of thinner and lighter steel components, reducing the overall weight of the aircraft. This, in turn, leads to lower fuel consumption, maintenance costs, and increased payload capacity. Furthermore, the durability and long lifespan of special steel reduce the need for frequent replacements, resulting in cost savings for the aerospace industry.

- Q: How is special steel used in the marine supply chain?

- Special steel is used extensively in the marine supply chain due to its exceptional strength, corrosion resistance, and durability. It is utilized in the construction of various marine components such as ship hulls, propeller shafts, offshore platforms, and marine equipment. Special steel ensures the structural integrity and longevity of these critical marine structures, enabling safe and efficient operations in harsh and corrosive marine environments.

- Q: What are the different non-destructive testing techniques used for special steel?

- There are several non-destructive testing (NDT) techniques that are commonly used for special steel to ensure its quality and integrity without causing any damage. These techniques are essential in industries where special steel is used, such as aerospace, automotive, and construction, to ensure that the material meets the required specifications and standards. Some of the commonly used NDT techniques for special steel are: 1. Ultrasonic Testing (UT): This technique involves the use of high-frequency sound waves to detect internal flaws, such as cracks, voids, or inclusions, in special steel. UT is highly effective in detecting subsurface defects and is widely used due to its versatility and accuracy. 2. Magnetic Particle Testing (MT): MT is a technique that uses magnetic fields and iron particles to detect surface or near-surface defects in special steel. It is particularly useful in identifying defects like cracks, seams, or laps, as the magnetic particles will accumulate at these locations, making them visible under proper lighting conditions. 3. Liquid Penetrant Testing (PT): PT is a widely-used method for detecting surface defects in special steel. It involves applying a liquid penetrant to the surface of the material, which seeps into any surface cracks or defects. After a specified time, the excess penetrant is removed, and a developer is applied to make the defects visible. 4. Eddy Current Testing (ET): ET utilizes electromagnetic induction to detect surface or near-surface defects in special steel. It is particularly useful in detecting cracks, corrosion, or metal loss in conductive materials. ET is a fast and accurate method, making it suitable for high-speed production environments. 5. Radiographic Testing (RT): RT involves the use of X-rays or gamma rays to examine the internal structure of special steel. It can detect various defects, including porosity, inclusions, and cracks. RT provides detailed images that help identify the location, size, and severity of defects. 6. Visual Testing (VT): VT is a simple yet crucial technique that involves a visual examination of the surface of special steel. It helps identify surface defects like scratches, dents, or corrosion. Although VT is not as sensitive as other NDT techniques, it is often used as a preliminary inspection method. Each of these non-destructive testing techniques has its own advantages and limitations. The selection of the appropriate technique depends on factors such as the type and size of the special steel, the required inspection depth, and the specific defects that need to be detected. By using a combination of these techniques, manufacturers and inspectors can ensure the quality and reliability of special steel products.

- Q: How are magnesium alloys used in lightweight structures?

- Magnesium alloys are used in lightweight structures due to their exceptional strength-to-weight ratio. They offer high tensile strength and stiffness, making them suitable for applications where weight reduction is crucial, such as in the aerospace and automotive industries. These alloys are commonly used in components like aircraft fuselages, engine casings, and lightweight vehicle parts, contributing to improved fuel efficiency and performance. Additionally, magnesium alloys can be easily cast, machined, and welded, allowing for efficient manufacturing processes.

- Q: How does special steel perform in high-wear applications?

- Special steel performs extremely well in high-wear applications. Its unique composition and properties, such as high hardness, toughness, and resistance to abrasion, make it highly durable and capable of withstanding intense wear and tear. This makes special steel an ideal choice for a wide range of demanding applications, including manufacturing tools, machinery parts, and components in industries such as mining, construction, and automotive. Overall, special steel's exceptional performance in high-wear applications ensures longevity, reliability, and cost-effectiveness.

Send your message to us

Grade AISI1045 Din1.1191 JIS s45c GB45 Hot Rolled Carbon Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords