GHI D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

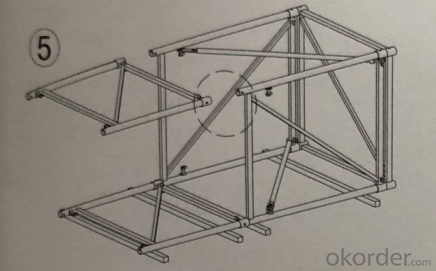

Fast & user-friendly, high load bearing towers for all shoring heights

High Load Bearing Towers for All Shoring Heights

• Using only 6 basic components any shoring height can be reached

• Each tower can take loads of up to 200kN making it an ideal shoring solution for all standard applications

• High load-bearing tower with minimum footprint of only 1m x 1m for increased workspace

• Efficient & Safe assembly following only a few basic steps

• Tower arrangements can be optimized by using the high load bearing capacities

Newly Introduced Rosettes for Increased Adaptability

• The Integrated Rosette Ring offers a wide range of possibilities for any job site

• With 8 new connection slots, the D-15 Tower now has 360 degrees of flexibility

• D-15 Towers can now be combined & connected with Modular scaffolding solution to achieve complex geometries in any structure

An Excellent investment for any Contractor

• All-rounded hot dip galvanisation guarantees a service life of over 10 years with minimum care and maintenance

• Few components decreases the chances of loss of material on a job site reducing part replacement costs

• The D-15 shoring can be utilized in various types of structures such as high-rises, water towers, silos etc. where high load concentration is required

• Efficient stacking of the towers reduces the amount of stocking area to store the system

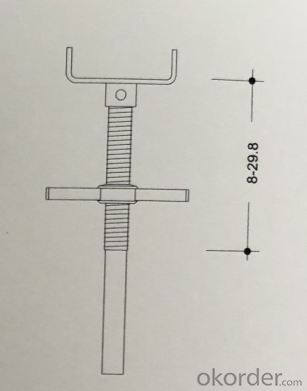

Head Jack 38/52

For bearing timber or steel beams. Slope of up to 6% can be compensated by the head plate.

Height adjustment: from 8 cm to 29.8 cm.

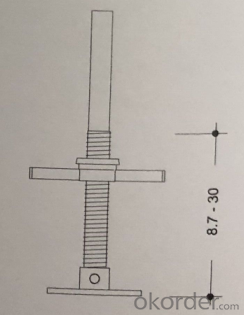

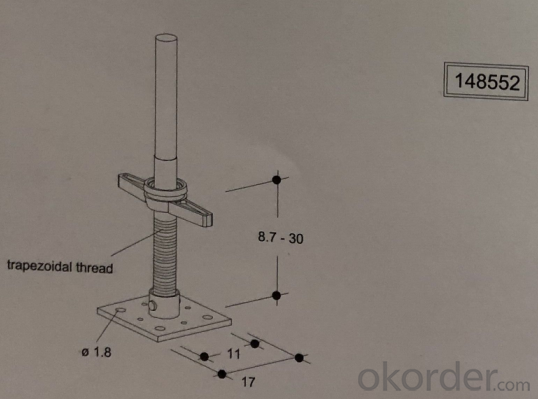

Base Jack 38/52

For setting-up the frame support. Slope of up to 6 % can be compensated by the head plate.

Height adjustment: from 8.7 cm to 30.0 cm

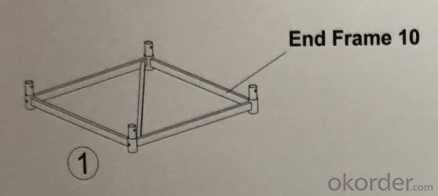

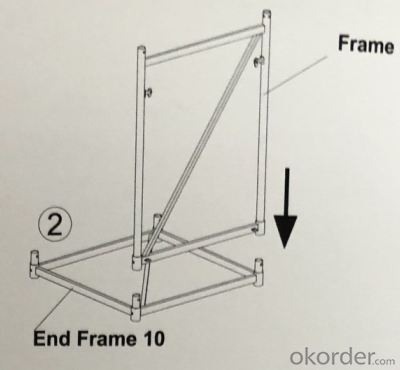

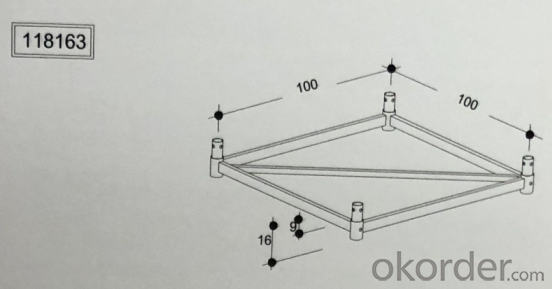

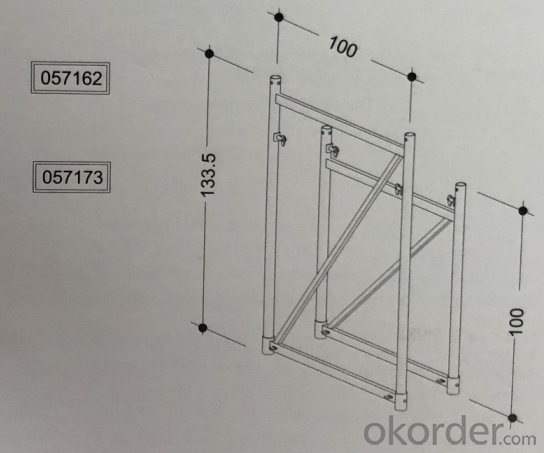

End Frame 10

To be assembled as sectional bracing of the frame support to ensure the square shape.

Always installed at the top and at the base.

Installation height at the top: 225px

installation height at the base: 400px

Frame 100

The frame are tension-resistantly connction with the tightly built-in wedges (quick- action connectors.)

Pins with gravity flips are provided for attaching the diagonals.

Design height of frame: 100 cm or 133.5 cm.

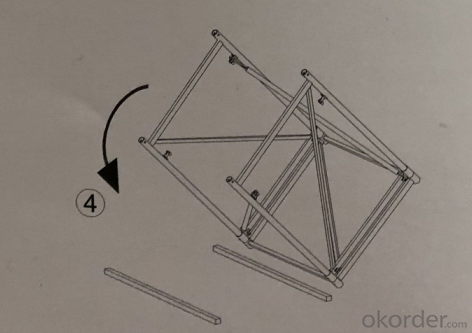

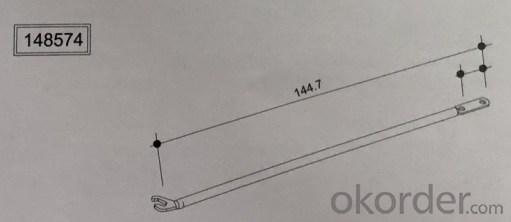

Diagonal

Used for bracing both types of frame within the tower at right angles to frame plane.

The lower end with its claws is fixed to the horizonal bottom bar of one frame, the upper end fixed to the hinged pin of the opposite frame.

- Q:What are the advantages of using steel props over traditional wooden supports?

- There are several advantages of using steel props over traditional wooden supports. Firstly, steel props offer greater strength and durability compared to wooden supports, making them more reliable and long-lasting. Secondly, steel props are adjustable, allowing for easy customization and adaptability to different heights and load-bearing requirements. Additionally, steel props are non-combustible, providing enhanced safety in situations where fire hazards are a concern. Lastly, steel props are lightweight and easy to handle, simplifying the transportation and installation process.

- Q:Can steel props be used in the construction of parking garages?

- Certainly, the utilization of steel props is possible in parking garage construction. Referred to as adjustable steel props or steel shores, these props are frequently employed as temporary supports in construction endeavors. Primarily crafted from top-notch steel, they possess the capacity to be modified to furnish the necessary support and stability essential throughout the construction phase. Temporary supports are often necessary in parking garage construction to guarantee the structure's safety and stability. Steel props are capable of providing support for beams, slabs, and other structural components during the construction period. Their application aids in the distribution of the structure's weight, preventing potential collapses or instabilities. Renowned for their robustness, durability, and adaptability, steel props prove suitable for a multitude of construction purposes, including parking garages. They exhibit the ability to endure substantial loads and supply the indispensable support requisite for preserving the parking garage's structural integrity during the construction process. Moreover, steel props possess adjustability, allowing for effortless installation and customization to meet specific project requirements. Their extendability and retractability enable accommodation of varying heights and support various structural features within the parking garage. To summarize, the integration of steel props is indeed feasible in parking garage construction. They furnish temporary support, stability, and strength to ensure the construction process maintains the safety and integrity of the structure.

- Q:What are the different load-bearing capacities of steel props?

- The load-bearing capacities of steel props can vary depending on several factors. These factors include the type and size of the steel prop, the material it is supporting, and the design specifications of the structure in which it is being used. Steel props are commonly used in construction to support temporary structures such as scaffolding, formwork, or shoring systems. They are designed to bear the load of the structure and ensure its stability and safety. The load-bearing capacity of a steel prop is typically measured in terms of its maximum vertical load or axial load. This refers to the maximum weight or force that the prop can support in a vertical direction without failure or deformation. Load-bearing capacities of steel props can range from a few hundred kilograms to several tonnes. The specific load-bearing capacity of a steel prop should be clearly indicated by the manufacturer and should comply with relevant safety standards and regulations. It is important to note that the load-bearing capacity of a steel prop can be affected by various factors such as the length of the prop, the angle at which it is positioned, and the condition of the ground or foundation on which it is placed. Therefore, it is crucial to carefully consider these factors and consult with structural engineers or experts when determining the appropriate load-bearing capacity of steel props for a specific application. In conclusion, the load-bearing capacities of steel props can vary depending on various factors. It is essential to consider the specific requirements of the application and consult with professionals to ensure the proper selection and use of steel props to ensure the safety and stability of the structure.

- Q:How do you ensure proper bracing of steel props in high wind conditions?

- To guarantee the adequate bracing of steel props during high wind conditions, it is essential to undertake several crucial steps. First and foremost, conducting a thorough assessment and analysis of the site is imperative in order to determine the wind load and pressure that the steel props will encounter. This assessment should take into account various factors such as prop height and size, location and surrounding environment, and any specific local wind codes or regulations. Once the wind load has been determined, the next step involves designing and implementing a suitable bracing system. This system should be specifically engineered to withstand the anticipated wind forces and prevent any structural failure or collapse. A commonly used method for bracing steel props in high wind conditions is the utilization of diagonal bracing. This entails connecting the props to the surrounding structure or foundation using diagonally positioned steel beams or cables. These diagonal braces aid in evenly distributing the wind forces and provide additional stability and rigidity to the props. Additionally, it is crucial to ensure that the bracing system is securely fastened and properly tightened. Loose or insufficient connections can undermine the effectiveness of the bracing and elevate the risk of failure. Regular inspections and maintenance should be carried out to promptly identify any loose or damaged bracing components and address them. Moreover, adherence to industry best practices and guidelines is vital when it comes to bracing steel props in high wind conditions. This involves consulting with structural engineers, following the manufacturer's recommendations, and complying with relevant building codes and standards. Lastly, closely monitoring weather conditions and being prepared to take necessary precautions in the event of severe weather or extreme wind conditions is of utmost importance. This includes having an emergency plan in place and implementing additional measures, such as temporary windbreaks or additional bracing, if required. In conclusion, ensuring the proper bracing of steel props during high wind conditions necessitates a comprehensive approach that includes site analysis, design of an appropriate bracing system, secure fastening, adherence to industry best practices, and monitoring of weather conditions. By following these steps, the risk of structural failure or collapse can be significantly minimized, ensuring the safety and stability of the steel props.

- Q:Are steel props safe to use in construction?

- Yes, steel props are generally considered safe to use in construction. They are designed to support and stabilize temporary structures, such as scaffolding, formwork, or falsework, providing reliable load-bearing capacity. However, it is important to ensure that the steel props are correctly installed, regularly inspected for damage or wear, and used within their specified load limits to maintain their safety.

- Q:Can steel props be used in the construction of historical monuments?

- Historical monuments can benefit from the utilization of steel props in their construction. These props are commonly employed in renovation or restoration projects to temporarily support structures. Their height can be adjusted as needed, and they are renowned for their strength and stability, making them ideal for reinforcing historical monuments. Preserving the original structure of historical monuments is of utmost importance. By strategically placing steel props, weak or damaged areas can receive the necessary support during repairs or restoration work. This helps distribute weight and enhances the stability of the structure, minimizing potential risks. Moreover, steel props offer versatility in terms of size and adjustability. This allows them to be easily customized to meet the specific requirements of each historical monument. Whether it's reinforcing fragile sections, temporarily supporting walls or ceilings, or aiding delicate architectural features during construction or restoration, steel props are up to the task. Nevertheless, it is crucial to ensure that the use of steel props does not compromise the authenticity and historical integrity of the monument. Proper planning and consultation with historical preservation experts are vital to ensure that the use of steel props respects and preserves the monument's original design and materials. In conclusion, steel props can be effectively employed in the construction of historical monuments to provide temporary support during renovation or restoration work. Their strength, adjustability, and versatility make them an ideal choice for reinforcing weak or damaged areas while preserving the historical integrity of the monument.

- Q:Can steel props be used in the installation of temporary lighting or sound equipment?

- Yes, steel props can be used in the installation of temporary lighting or sound equipment. Steel props, also known as adjustable steel props or steel shoring props, are commonly used in construction to support temporary structures or loads. They are designed to provide stability and strength, making them suitable for a wide range of applications including the installation of temporary lighting or sound equipment. Steel props are adjustable in height, allowing for precise positioning and alignment of equipment. They can be easily extended or retracted to accommodate different heights or uneven surfaces. Additionally, their robust construction ensures they can withstand the weight and pressure of lighting or sound equipment, providing a secure and stable support. Moreover, steel props are easy to install and dismantle, making them ideal for temporary setups where equipment needs to be quickly set up or removed. They are often used in events such as concerts, festivals, or theater productions where lighting and sound equipment are frequently required to be installed and removed within a short period of time. In summary, steel props are a reliable and versatile solution for the installation of temporary lighting or sound equipment. Their adjustable height, strength, stability, and ease of use make them well-suited for such applications.

- Q:Can steel props be used in shopping mall construction?

- Yes, steel props can be used in shopping mall construction. Steel props are commonly used in construction projects to provide temporary support for structures, including shopping malls. They are adjustable and versatile, making them suitable for various construction needs, such as formwork support, load-bearing support, and temporary shoring. Steel props offer stability and strength, making them a reliable choice for supporting large structures like shopping malls during the construction process.

- Q:Can steel props be used for temporary support during renovations?

- Certainly, temporary support during renovations can be achieved by using steel props. These props, also known as adjustable steel props or acrow props, are widely utilized in construction and renovation endeavors to offer temporary support to structures. Their adjustable height feature makes them adaptable and appropriate for various applications. When conducting renovations that involve the removal or modification of walls or other supporting structures, steel props can be employed to provide temporary support until the necessary work is finished. Typically, these props are positioned beneath beams, ceilings, or floors to prevent any potential collapse or structural damage. Steel props are renowned for their strength, stability, and capacity to bear heavy loads. They are engineered to withstand substantial weights and provide dependable support, ensuring the safety of workers and the structure itself during renovations. The adjustable nature of these props enables precise height adjustments, guaranteeing a proper fit and support for diverse construction and renovation requirements. In addition to their strength and adjustability, steel props are also effortless to install and remove. This convenience makes them an ideal choice for temporary support during renovations, as they can be swiftly set up and dismantled as required. Overall, steel props are a trustworthy and frequently employed solution for temporary support during renovations. They offer stability, load-bearing capacity, and versatility, making them suitable for a broad range of construction and renovation projects.

- Q:What are the common methods of testing steel props for structural integrity?

- The common methods of testing steel props for structural integrity include visual inspection, ultrasonic testing, magnetic particle inspection, and load testing. Visual inspection involves examining the props for any visible defects such as corrosion, cracks, or deformation. Ultrasonic testing uses high-frequency sound waves to detect internal flaws or discontinuities in the material. Magnetic particle inspection uses magnetic fields and iron particles to identify surface defects or cracks. Load testing involves applying a predetermined load to the prop to assess its capacity and behavior under stress. These methods help ensure the reliability and safety of steel props in structural applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GHI D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords