Construction Support Heavy Duty Adjustable Steel Prop

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction Heavy Duty Support Steel Props

Specifications of Steel Props:

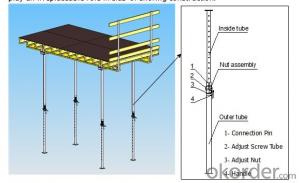

1. Steel Prop consists of internal pipe, external pipe, prop sleeve, nut, pin, top and bottom plate.

2. Steel Prop is widely used as support system in beam, slab, formwork, concrete and floor support.

3. Steel Prop can be surface treatment red oil painting or powder coated or galvanized to further resist rust, cracking and corrosion, has no pollution or harm to the environment and human body, which make sure of its low damage and longer life span.

4. Steel Prop has fewer components, easy and quick assembly.

5. Steel Props has high bearing capacity, as steel pipe material is Q235, thickness can be 1.8mm to 3.0mm, diameter 40-48mm,48-56mm,48-60mm. According to SGS test report, one prop with 2.2mm of thickness, 48-60mm diameter can load 1.8tons, which is heavy duty Steel Props .

6.We can meet all kinds of steel props , Italian tye, Spanish type for South Amercia, Middle East type. aole the requiremnets, such as U head, fork head, rosette head, plate, etc.

Technical parameters

Model Number: adjustable steel prop

Material: Q235 steel tube raw material

Surface Treatment: Galvanized,Dip Painted,Powder coated

Color: silver,dark red,yellow,blue,green and more colore

Application: building construction shoring props for inside concrete wall support

tube thickness: 1.8/2.0/2.2/2.5/3.0mm

adjustable length: 1600-2900/1800-3200/2000-3600/2200-4000mm as your request

base plate size: 120*120*5mm or as your request

Working life: 4-6 years normally

inner tube diameter: 40mm,or 48mm

outer tube diameter: 48mm,or 56/58/60mm

Packaging & Delivery

In bulk or steel pallet. props will be bundle with wooden pallet or bare package in container one 20ft container can load steel props 1800pcs to 2500pcs.

20 to 30 days to main port of China after order confirmation

- Q:Are steel props easy to install and dismantle?

- Yes, steel props are generally easy to install and dismantle. Steel props, also known as adjustable steel props or scaffolding props, are commonly used in construction projects to support temporary structures such as scaffolding, formwork, or shoring systems. The installation process usually involves positioning the props in the desired locations and adjusting their height according to the specific requirements of the project. Most steel props have an adjustable mechanism that allows for easy height adjustment, making it convenient to adapt to different construction needs. Similarly, dismantling steel props is typically a straightforward process. Once the temporary structure is no longer needed, the props can be easily removed by reversing the installation process. This usually involves lowering the props to their lowest height, releasing any locking mechanisms, and then removing them from their positions. Furthermore, steel props are often designed with lightweight materials, such as aluminum or steel alloy, which enhances their portability and ease of handling. This makes it easier for construction workers to install, adjust, and dismantle them as needed, saving time and effort during construction or renovation projects. However, it is important to note that the exact ease of installation and dismantling may vary depending on the specific design and manufacturer of the steel props. Additionally, proper training and adherence to safety guidelines are crucial to ensure the correct installation and dismantling procedures are followed, minimizing any potential risks or accidents.

- Q:What are the different locking mechanisms available for steel props?

- There are several different locking mechanisms available for steel props, depending on the specific needs and requirements of the project. Some of the commonly used locking mechanisms for steel props include: 1. Pin and chain: This is a simple and cost-effective locking mechanism where a pin is inserted through holes on the outer tube of the prop, and a chain is attached to prevent loss of the pin. This mechanism allows for quick and easy adjustment of the prop height. 2. Collar and pin: In this mechanism, a collar is placed around the outer tube of the prop, and a pin is inserted through holes on both the collar and the outer tube to secure the desired height. It provides a more secure locking system compared to pin and chain. 3. Twist-lock: This locking mechanism involves a threaded collar on the outer tube of the prop. By twisting the collar, it engages with the inner tube and locks it in place. This mechanism offers quick and precise height adjustment with a secure locking system. 4. Quick-release: This locking mechanism allows for rapid installation and removal of the prop. It typically involves a lever or a handle that, when engaged, secures the prop in place, and when released, allows for easy removal. Quick-release mechanisms are commonly used in applications where frequent adjustments are required. 5. Prop clamps: These locking mechanisms involve clamps or brackets that secure the prop in place. They are commonly used in heavy-duty applications where a high load-bearing capacity is required. Prop clamps offer a strong and secure locking system that can withstand substantial forces. It is important to consider the specific requirements of the project, such as load capacity, ease of adjustment, and speed of installation, while selecting the appropriate locking mechanism for steel props. Consulting with a structural engineer or a construction professional can help in determining the most suitable locking mechanism for a particular application.

- Q:Can steel props be used to support beams or columns?

- Steel props, otherwise referred to as adjustable steel props or steel shore props, have the capability to support beams or columns. Frequently employed in construction, these props possess the ability to accommodate varying heights, rendering them adaptable and appropriate for a range of purposes, including the support of beams or columns. The primary intention behind the design of steel props is to furnish provisional support throughout the course of construction or renovation undertakings, thereby enabling the secure installation or removal of structural components. Typically composed of superior-quality steel, these props are esteemed for their robustness and dependability, ultimately establishing them as a trustworthy option for sustaining substantial loads such as beams or columns.

- Q:Are steel props suitable for use in offshore wind farm construction?

- Steel props are well-suited for use in the construction of offshore wind farms. They are commonly employed in construction projects, including offshore wind farms, due to their robustness, endurance, and adaptability. The construction of offshore wind farms necessitates sturdy and dependable support structures that can withstand harsh weather conditions and provide stability for wind turbines. Steel props possess exceptional load-bearing capacity and can endure the dynamic forces exerted by wind and waves. Furthermore, steel is resistant to corrosion, a vital characteristic in the offshore environment where exposure to saltwater and moisture is high. Additionally, steel props can be easily modified and tailored to meet specific project requirements, making them highly flexible for various offshore wind farm designs. All in all, steel props are a suitable choice for offshore wind farm construction due to their strength, endurance, resistance to corrosion, and adaptability.

- Q:Can steel props be used for supporting prefabricated structures?

- Yes, steel props can be used for supporting prefabricated structures. Steel props are adjustable and sturdy support systems that can be used to provide temporary or permanent support to various types of structures, including prefabricated ones. These props are typically made of high-quality steel and are designed to be strong enough to bear the weight of the structure they are supporting. They can be easily adjusted and secured in place to provide the necessary support during construction or installation of prefabricated structures. Steel props are commonly used in the construction industry for a wide range of applications, including supporting prefabricated structures.

- Q:Are steel props suitable for supporting temporary art installations or sculptures?

- Yes, steel props are suitable for supporting temporary art installations or sculptures. Steel is known for its strength, durability, and load-bearing capacity, making it an ideal choice for supporting heavy and intricate artworks. Moreover, steel props can be easily customized to meet the specific requirements of the installation or sculpture. They can be designed to provide stability, balance, and secure placement, ensuring that the artwork remains safely supported throughout its display period. Additionally, steel props can be adjusted in height and angle, allowing for flexibility in positioning the artwork for optimal viewing angles. Overall, steel props offer a reliable and versatile solution for supporting temporary art installations or sculptures, ensuring the safety and longevity of the artwork.

- Q:Can steel props be used in both residential and commercial construction?

- Yes, steel props can be used in both residential and commercial construction. Steel props, also known as adjustable steel props or steel acrow props, are versatile and can support heavy loads during construction. They are commonly used to support formwork, ceilings, beams, and walls. In residential construction, steel props can be used to provide temporary support for load-bearing walls during renovations or alterations. They are particularly useful in situations where walls need to be removed or openings need to be enlarged. Steel props can also be used to support temporary structures such as scaffolding or to provide additional support to weak or damaged structures. In commercial construction, steel props are widely used for various applications. They can be used to support beams or slabs during concrete pouring, ensuring the structural integrity of the building. Steel props are also commonly used in shoring systems to support excavation works, enabling safe construction in deep trenches or basements. Overall, steel props offer a reliable and efficient solution for temporary structural support in both residential and commercial construction. They are adjustable, easy to install, and can withstand heavy loads, making them suitable for a wide range of construction projects.

- Q:What are the potential aesthetic considerations when using steel props?

- When incorporating steel props, one must keep in mind various aesthetic factors. Firstly, the overall aesthetic of a space can be influenced by the appearance of the steel props themselves. Contemporary or minimalist designs may find the sleek and industrial look of steel props appealing. However, in traditional or rustic settings, steel props may clash with the desired aesthetic. In such cases, alternative materials or finishes may need to be considered to blend the steel props with the overall design scheme. The visibility of the steel props within the space is another aesthetic consideration. Depending on the design intent, some may prefer the steel props to be prominently displayed as a design feature, while others may prefer them to be discreetly hidden. Careful consideration should be given to the size, shape, and placement of the steel props to ensure they align with the desired aesthetic and do not detract from the overall visual appeal of the space. The surface finish and treatment of the steel props can also impact their aesthetic appeal. Steel props can be left in their raw state, showcasing a natural steel finish that adds an industrial and rugged charm. Alternatively, they can be painted or powder-coated to match the surrounding elements or achieve a specific color scheme. The choice of finish should harmonize with the overall aesthetic goals of the space and enhance its visual appeal. Lastly, the integration of steel props with other materials and elements in the design is an important aesthetic consideration. Steel props can be used alongside materials such as wood, glass, or concrete, and the combination of these materials must be carefully considered to achieve a cohesive aesthetic. The juxtaposition of steel with other materials can create interesting visual contrasts, but it is crucial to strike a balance and ensure that the combination enhances the overall aesthetic rather than creating a discordant visual effect. In conclusion, when using steel props, it is essential to consider their appearance, visibility, surface finish, and integration with other materials. By carefully evaluating these factors, designers can create a harmonious and visually appealing space that aligns with their aesthetic goals.

- Q:What is the typical warranty period for steel props?

- The warranty period for steel props usually fluctuates based on the manufacturer and the specific product. Nevertheless, it is not uncommon to come across warranty periods ranging from 1 to 5 years for steel props. Certain manufacturers may even extend longer warranty periods for their top-notch or superior props. To guarantee that you have knowledge of the precise warranty period, along with any applicable conditions or limitations, it is crucial to examine the warranty information provided by the manufacturer or supplier before purchasing steel props.

- Q:Can steel props be used in the construction of residential buildings?

- Yes, steel props can be used in the construction of residential buildings. Steel props provide temporary support during construction and can be adjusted to suit the specific requirements of the project. They are commonly used for supporting beams, walls, and slabs, ensuring stability and safety during the construction process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Construction Support Heavy Duty Adjustable Steel Prop

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords