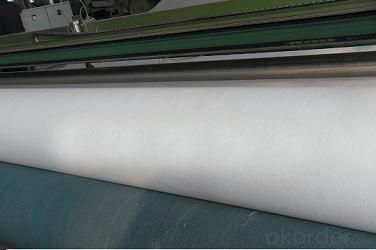

Woven Geotextile Fabric Suppliers for Polyester Geotextile in Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Geotextile Description

Polyester non woven geotextile is made from polyester short fiber by non woven needle punched manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and maintenance function.

2. Polyester Nonwoven Geotextile Specification:

No | Project | Index | ||||||

1 | Breakage Strength KN/m≥(MD) | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

2 | Breakage Strength KN/m≥(CD) | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

3 | Elongation Rate (MD,CD) ≤ | 28 | ||||||

4 | Trapezoidal Tearing Strength | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

5 | Burst Strength KN≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

6 | Vertical Permeability Coefficient cm/s | 10-1~10-3 | ||||||

7 | Sieve size(O95) mm | 0.08~0.5 | ||||||

8 | Unit weight g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

9 | Thickness mm | 0.40 | 0.48 | 0.60 | 0.70 | 0.80 | 1.00 | 1.25 |

10 | Variation % | ±10 | ||||||

3. FAQ:

We have organized several common questions for our clients, may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2:Can you send samples to us ?

A2:Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

Q3:What’s your Payment term ?

A3:T/T , L/C , Western Union,Paypal ...

Q4:What’s your manufacture process time ?

A4:Usually within 20 days

- Q: How do geotextiles help with sediment control in construction sites?

- Geotextiles are used in construction sites to help with sediment control by acting as a barrier that traps sediment and prevents it from being washed away by water runoff. These permeable fabrics allow water to pass through while retaining the sediment, reducing erosion and preventing pollution of nearby water bodies.

- Q: How do geotextiles help with soil reinforcement in retaining walls?

- Geotextiles help with soil reinforcement in retaining walls by acting as a barrier between the soil and the backfill material. They prevent soil erosion and provide stability by distributing the pressure evenly across the wall. Additionally, geotextiles enhance the overall strength and longevity of the retaining wall system.

- Q: In ANSYS, geotextile what unit to simulate it?

- I am now doing geotextile simulation, before someone with shell63, I now use, but the shell and the physical contact I did a long time. The

- Q: Can geotextiles be used in waste containment systems?

- Yes, geotextiles can be used in waste containment systems. They are commonly employed as a barrier or liner material to prevent the escape or migration of waste materials, such as leachate, from landfills or other waste disposal sites. Geotextiles provide reinforcement, filtration, and separation properties, helping to stabilize the waste and protect the environment by reducing the risk of contamination.

- Q: Are geotextiles resistant to freeze-thaw cycles?

- Yes, geotextiles are generally resistant to freeze-thaw cycles. They are designed to withstand various environmental conditions, including freezing temperatures and the repetitive expansion and contraction caused by freeze-thaw cycles.

- Q: What are the advantages of using geotextiles in green roof design?

- Geotextiles offer several advantages in green roof design. Firstly, they provide an effective separation layer between the growing media and the roof membrane, preventing soil erosion and protecting the waterproofing layer. Secondly, geotextiles enhance drainage by allowing excess water to pass through the growing media and into the drainage layer, preventing waterlogging and maintaining a healthy environment for plant growth. Additionally, geotextiles can act as a filtration layer, preventing fine particles from clogging the drainage system and maintaining its functionality. Overall, the use of geotextiles in green roof design improves the longevity and performance of the roof system, while also aiding in stormwater management and plant health.

- Q: What are the key factors affecting the clogging behavior of geotextiles?

- The key factors affecting the clogging behavior of geotextiles include the size and type of particles in the surrounding soil, the hydraulic gradient, the flow rate and duration of water passing through the geotextile, and the quality and depth of the geotextile itself.

- Q: Waterproof geotextile how much money per square meter

- This depends on the specifications and quality, the detailed explanation can see my user name

Send your message to us

Woven Geotextile Fabric Suppliers for Polyester Geotextile in Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords