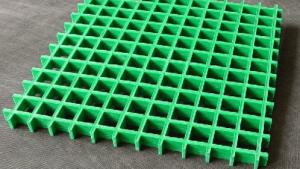

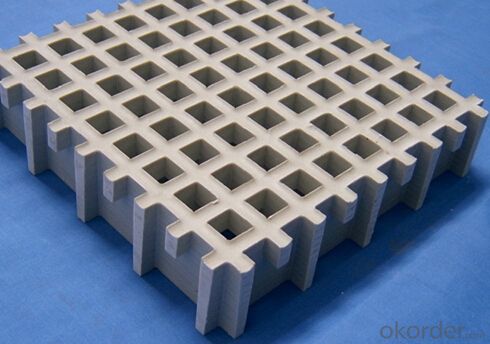

FRP Molded Grating For All Kinds Of Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description of FRP Grating

FRP Grating, Molded FRP Grating, Fiberglass Grating, GRP Grating,GRP Molded Grating,FRP Pultrusion Grating, FRP Mini Mesh Grating,Trench Grating, Drain Grating,Grating Walkway, Platform Grating...

Comparing with other floor materials, FRP molded grating provides a series of benefits, unmatched impact resistance,

while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install.

Specification of FRP Grating

Item | Thickness mm | Mesh Size mm*mm | Panel Size mm*mm | Weight kg/Square Meter |

01 | 15 | 38*38 | 1223*3660 | 7 |

02 | 15 | 50*50 | 1223*3660 | 6.5 |

03 | 25 | 25*100 | 1010*3010 | 12.4 |

04 | 25 | 19*19 | 1223*3660 | 12.5 |

05 | 30 | 19*19 | 1223*3660 | 21.5 |

06 | 30 | 38*38 | 1223*4040 | 15.1 |

07 | 38 | 19*19 | 1223*3660 | 22.8 |

08 | 38 | 38*38 | 1000*4040 | 19.5 |

09 | 38 | 38*38 | 1223*3660 | 19.5 |

10 | 40 | 40*40 | 1250*3690 | 19.3 |

11 | 50 | 50*50 | 1223*3660 | 21.5 |

Images

Features

1.Corrosion and Chemical resistant

2.Slip-resistant

3.High strength-to-weight ratio

4.Ergonomic

5.Low maintenance

6.Fire retardant

7.Easily fabricated and installed

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

- Q:Are FRP pultrusion profiles resistant to fire?

- FRP pultrusion profiles are known for their fire resistance. They are composed of a resin matrix and reinforcing fibers, such as fiberglass or carbon fiber, which contribute to their excellent fire resistance properties. The resin matrix used in FRP has a high flame resistance rating, while the reinforcing fibers are not easily combustible. Consequently, FRP pultrusion profiles have a high ignition temperature and are naturally self-extinguishing, meaning they stop burning once the flame source is removed. Moreover, FRP pultrusion profiles do not emit toxic fumes or smoke when exposed to fire, making them a safer choice compared to traditional materials like wood or steel. Nevertheless, it is important to acknowledge that the fire resistance of FRP pultrusion profiles may vary depending on the specific resin formulation and reinforcement material utilized.

- Q:Can FRP pultrusion profiles be used in the production of electrical busbars?

- Yes, FRP pultrusion profiles can be used in the production of electrical busbars. FRP (Fiber Reinforced Plastic) pultrusion profiles offer several advantages such as high strength, excellent electrical insulation properties, and resistance to corrosion, making them suitable for use in electrical applications like busbars. They provide a lightweight and durable alternative to traditional materials like copper or aluminum, and their non-conductive nature ensures safety in electrical systems.

- Q:Are FRP pultrusion profiles resistant to alkalis?

- FRP pultrusion profiles are generally able to resist alkalis. This is because FRP composites are materials made of a polymer matrix reinforced with fibers like glass or carbon. The polymer matrix in FRP pultrusion profiles has excellent resistance to alkalis, making them suitable for use in places where alkalis are present, such as chemical processing plants, wastewater treatment facilities, or marine structures. However, the resistance of FRP pultrusion profiles to alkalis may vary depending on factors like the type of polymer resin used and the concentration and temperature of the alkali solution. Therefore, it is important to refer to the manufacturer's specifications or perform specific tests to ensure that FRP pultrusion profiles are compatible with the intended alkali environment.

- Q:Are FRP pultrusion profiles resistant to UV degradation?

- Yes, FRP pultrusion profiles are generally resistant to UV degradation. Pultrusion profiles made from fiberglass reinforced plastic (FRP) are manufactured using a combination of resin and glass fibers. The resin used in the manufacturing process is typically formulated to provide resistance to UV radiation. This UV resistance helps to protect the FRP pultrusion profiles from the harmful effects of prolonged exposure to sunlight. FRP pultrusion profiles have been extensively tested and have demonstrated excellent resistance to UV degradation. They are commonly used in outdoor applications where they are exposed to sunlight, such as in construction, infrastructure, and marine industries. UV resistance ensures that the FRP pultrusion profiles maintain their structural integrity, color, and aesthetic appearance over an extended period of time. However, it is important to note that the level of UV resistance may vary depending on the specific formulation of the resin used in the manufacturing process. Different manufacturers may use different resins with varying levels of UV stabilizers. It is recommended to consult with the manufacturer or supplier to ensure that the specific FRP pultrusion profiles being used are designed to withstand the UV conditions of the intended application. Regular maintenance and periodic inspection of the FRP pultrusion profiles are also important to ensure their long-term UV resistance. This may include cleaning, applying protective coatings, or using UV-blocking additives if necessary. By taking these precautions, the UV resistance of FRP pultrusion profiles can be further enhanced, ensuring their durability and longevity in outdoor environments.

- Q:Can FRP pultrusion profiles be used in the construction of wind turbine blades?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the construction of wind turbine blades. These profiles offer high strength-to-weight ratio, excellent corrosion resistance, and can be custom-designed to meet the specific requirements of wind turbine blade construction. Additionally, FRP pultrusion profiles provide flexibility in design and can withstand the demanding conditions of wind turbine operation, making them a suitable choice for blade construction.

- Q:Are FRP pultrusion profiles resistant to high winds or hurricanes?

- FRP pultrusion profiles offer exceptional resistance against high winds and hurricanes. Combining the robustness of fiberglass with the longevity of polymers, FRP is a lightweight yet remarkably sturdy material that can endure severe weather conditions. Extensive testing has proven that FRP pultrusion profiles exhibit outstanding wind resistance properties. They possess a remarkable stiffness-to-weight ratio, enabling them to withstand the powerful forces generated by high winds without deformation or breakage. Additionally, the inherent flexibility of FRP permits it to absorb and distribute wind forces, minimizing the risk of damage. In the face of hurricanes, FRP pultrusion profiles have demonstrated their capability to withstand the intense winds and airborne debris associated with such extreme weather events. They have been successfully employed in various applications, including building facades, bridges, and utility poles, in areas prone to hurricanes. Moreover, FRP pultrusion profiles possess corrosion resistance, providing an extra advantage in withstanding high winds and hurricanes. Unlike traditional materials like steel or wood, FRP profiles do not rust or decay when exposed to moisture, making them even more suitable for these demanding weather conditions. Overall, with their exceptional strength, durability, flexibility, and corrosion resistance, FRP pultrusion profiles are an excellent choice for applications requiring resistance against high winds or hurricanes.

- Q:Can FRP pultrusion profiles be used in oil and gas applications?

- FRP pultrusion profiles are applicable for oil and gas purposes. These profiles possess exceptional resistance against corrosion, a high strength-to-weight ratio, and durability, making them suitable for a range of industries, including oil and gas. In oil and gas applications, FRP pultrusion profiles can serve multiple functions. They find use in constructing pipelines, offshore platforms, and subsea structures. They can also be utilized for fabricating tanks, vessels, and other equipment that are exposed to corrosive environments. A key advantage of FRP pultrusion profiles in oil and gas applications is their resistance to corrosion. Unlike traditional materials like steel, FRP does not rust or corrode when exposed to moisture, chemicals, or saltwater. This resistance extends the lifespan of the profiles and reduces maintenance costs. Furthermore, FRP pultrusion profiles offer high strength and stiffness. They can withstand high pressures, extreme temperatures, and harsh operating conditions commonly encountered in oil and gas environments. Their lightweight nature also facilitates easier handling and installation, especially when compared to heavier materials such as steel. Another benefit of FRP profiles is their non-conductive property. This characteristic makes them suitable for applications where electrical conductivity should be minimized, such as offshore platforms or areas with potential electrical hazards. In conclusion, FRP pultrusion profiles are a reliable and cost-effective solution for oil and gas applications. Their corrosion resistance, high strength, and lightweight properties make them ideal for various components and structures within the industry.

- Q:What are the characteristics of FRP products?

- Good electrical performanceIt is a good insulating material used for making insulators. High dielectric protection can be maintained at high frequencies. Microwave permeability is good, and has been widely used in radome.

- Q:What is the compression strength of FRP pultrusion profiles?

- The compression strength of FRP pultrusion profiles can vary depending on the specific design and manufacturing process. However, on average, FRP pultrusion profiles typically exhibit compression strengths ranging from 20,000 to 40,000 pounds per square inch (psi).

- Q:Can FRP pultrusion profiles be used in chemical storage tanks?

- Indeed, it is possible to utilize FRP pultrusion profiles in the construction of chemical storage tanks. These profiles are recognized for their exceptional resistance to corrosion, rendering them suitable for the storage of a wide array of chemicals. Moreover, their lightweight nature, strength, and impressive strength-to-weight ratio make them an optimal choice for the creation of robust and long-lasting chemical storage tanks. Furthermore, FRP pultrusion profiles can be tailor-made to fulfill specific design requirements, enabling flexibility in tank design and construction. In summary, due to their corrosion resistance, strength, and customization capabilities, FRP pultrusion profiles emerge as a dependable and cost-efficient alternative for chemical storage tanks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Molded Grating For All Kinds Of Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords