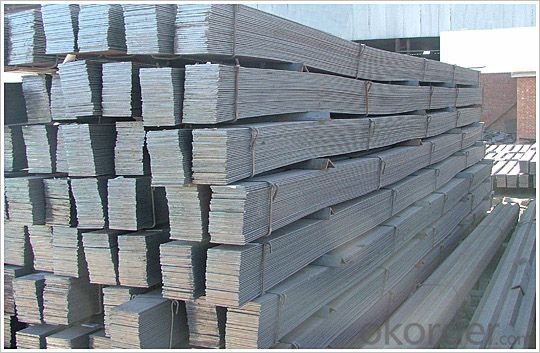

Flat Bar High Quality Steel Flat Bar,Flat Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy export packed |

| Delivery Detail: | 20-25 days |

Specifications

High Quality steel flat bar,flat steel,flat bar

1. Q235,Q345,SS400,ASTM A36,S235JR,S275JR

2. USD 495-516/Ton

3. Free Sample

flat steel,Steel Flat Bar, Galvanized Flat Bar,SS400 flat steel,galvanized flat steel

typical size range: | 10*3 – 300*25mm 6 – 12M Long (special lengths can also be provided) |

Available specifications: | EN 10025 GB/T704-2004 JIS G3101 |

Steel grades: | S235JR, S355JR, Q235B, Q345B, SS400 |

Application of Flat Bar

Flat Bar is used for general fabrication, making structures and frames. Mild Steel Flat Bar can be easily cut and drilled, and is particularly suited to welding. Examples of its use include furniture making, machinery manufacturing, shipbuilding, railway spare parts, iron towers, steel structures, and boilers.

1. What grades and standards of steel are used for your production?

Our grades could meet most of customers demand, such as ASTM, GB, JIS, EN etc…Specific grades include commercial quality, low carbon; high carbon and high strength select low alloys.

2. What type of finishes is your product produced in?

We produce steel product in a wide variety of finishes, including hot-rolled black, hot-rolled pickled & oiled, cold-rolled, aluminized, and hot dipped galvanized. If you have a specific finish that is required, please contact us for additional information.

3. What is your order minimum?

As an experienced steel materials manufacturer, we sell in one full container and combination container. Although the total weight on an order will vary due to the type and size, a typical full container load or less container load order will be approximately 15-25 tons.

4. What could we get if we build up relationship with you company?

Frankly, you get competitive price, good quality materials and considerable payment term. Our experienced team will offer you full service from order confirmation to goods arrival your warehouse. You have nothing to worry about during the process.

- Q:What are the different types of tests performed on steel flat bars?

- The different types of tests performed on steel flat bars include visual inspection, dimensional measurement, tensile testing, hardness testing, impact testing, and chemical analysis.

- Q:The technological process of flat steel

- The production process can be summarized as: pre leveling, finishing, straightening and leveling. Flat /a/b width 12-300mm, thickness 4-60mm, cross section is rectangular and with pure edge of steel. Flat steel can be finished steel, or can be used as the blank of welded pipe and thin slab for laminated sheet rolling. Main application: flat steel is used as a material, used for making iron, tools and machinery parts, and used as frame structures and escalators for buildings. Flat steel is divided into two kinds according to its shape: flat spring, flat steel and single side double slot spring flat steel. Hot rolled spring flat steel is mainly used in the manufacture of automobiles, tractors, railway transportation and other mechanical leaf springs.

- Q:Are steel flat bars available in different surface hardness options?

- Yes, steel flat bars are available in different surface hardness options. The hardness of steel flat bars can be modified through various heat treatment processes to achieve different levels of hardness, such as annealing, quenching, and tempering. This allows for customization based on specific application requirements.

- Q:Can steel flat bars be used as support beams?

- Yes, steel flat bars can be used as support beams as they have high strength and load-bearing capacity. However, it is important to consider the specific requirements and structural calculations to ensure they are suitable for the intended purpose and meet the necessary safety standards.

- Q:Can steel flat bars be used for making hydraulic systems or components?

- No, steel flat bars are not typically used for making hydraulic systems or components. Hydraulic systems require materials that have specific characteristics, such as high strength, flexibility, and resistance to corrosion and abrasion. Steel flat bars are generally not designed to meet these requirements. Instead, hydraulic systems and components are typically made from materials such as stainless steel, aluminum, or certain types of steel that are specifically engineered for hydraulic applications. These materials offer the necessary properties to ensure the efficient and reliable operation of hydraulic systems.

- Q:What are the load-bearing capacities of steel flat bars?

- The load-bearing capacities of steel flat bars vary depending on various factors such as the dimensions of the bar, the type of steel used, and the specific application. Steel flat bars are commonly used in construction, manufacturing, and structural engineering projects due to their strength and durability. To determine the load-bearing capacity of a steel flat bar, engineers and designers typically refer to industry standards and guidelines such as those provided by the American Institute of Steel Construction (AISC) or the European Committee for Standardization (EN). These standards provide design tables and equations that consider the dimensions of the bar, the steel grade, and the desired safety factors. In general, the load-bearing capacity of a steel flat bar is influenced by its width, thickness, and the distance between supports or points of load application. Wider and thicker bars tend to have higher load-bearing capacities. Additionally, the type of steel used can also affect the load-bearing capacity as different steel grades have varying levels of strength and resilience. It is important to note that load-bearing capacities are typically expressed in terms of maximum allowable loads or uniform load distribution. The specific load-bearing capacity of a steel flat bar can only be determined through proper engineering calculations that consider all relevant factors and safety standards. Therefore, it is recommended to consult with a structural engineer or refer to appropriate industry standards when determining the load-bearing capacities of steel flat bars for a specific application.

- Q:Are steel flat bars suitable for electrical conductivity applications?

- No, steel flat bars are not suitable for electrical conductivity applications.

- Q:What are the load capacities of steel flat bars?

- The load capacities of steel flat bars vary depending on their dimensions and the specific grade of steel used. However, steel flat bars are known for their high strength and load-bearing capacity, making them suitable for various applications such as construction, manufacturing, and structural support. It is important to consult engineering specifications and calculations to determine the precise load capacities for a specific steel flat bar.

- Q:What are the different methods of finishing the edges of steel flat bars?

- There are several methods of finishing the edges of steel flat bars, each with their own advantages and applications. 1. Cutting: One of the simplest methods is cutting the edges of the flat bar to the desired length or shape. This can be done using various cutting tools such as shears, saws, or plasma torches, depending on the thickness and hardness of the steel. Cutting provides a clean and precise finish, making it suitable for most applications. 2. Grinding: Grinding the edges of steel flat bars helps achieve a smooth and polished finish. This process involves using a grinding wheel or belt sander to remove any rough edges or burrs, resulting in a clean and professional look. Grinding is commonly used for decorative purposes or when a smooth surface is required. 3. Deburring: Deburring is a process that removes the burrs or sharp edges left after cutting or grinding. This can be done manually using a file or deburring tool, or by employing a vibratory or tumbling machine. Deburring ensures safety and improves the overall appearance of the flat bar. 4. Beveling: Beveling refers to the process of creating angled edges on the flat bar. This is often done to enhance weldability or to create a chamfered edge for aesthetic purposes. Beveling can be achieved using specialized tools like beveling machines or by hand with a grinder. 5. Galvanizing: Galvanizing is a process that involves coating the steel flat bar with a layer of zinc to protect it from corrosion. This method is commonly used in applications where the flat bar will be exposed to harsh environmental conditions or moisture. Galvanizing not only provides a protective coating but also gives the flat bar a shiny and attractive finish. 6. Powder Coating: Powder coating is a technique where a dry powder is applied to the steel flat bar and then cured under heat to form a protective and decorative layer. This method offers a wide range of colors and finishes, making it ideal for applications where aesthetics are important, such as furniture or architectural elements. 7. Anodizing: Anodizing is primarily used for aluminum, but it can also be applied to steel flat bars to provide corrosion resistance and improve the surface finish. This process involves creating an oxide layer on the steel's surface through an electrochemical reaction. Anodized steel flat bars are commonly used in the construction and automotive industries. In conclusion, the different methods of finishing the edges of steel flat bars include cutting, grinding, deburring, beveling, galvanizing, powder coating, and anodizing. Each method offers unique benefits and is chosen based on the desired functionality, appearance, and durability required for the specific application.

- Q:Are steel flat bars suitable for making electrical enclosures or cabinets?

- Yes, steel flat bars are suitable for making electrical enclosures or cabinets. Steel flat bars offer excellent strength and durability, making them ideal for providing adequate protection and support for electrical components. They can also be easily welded or bolted together, allowing for the construction of custom designs and configurations. Additionally, steel flat bars can withstand various environmental conditions, ensuring the longevity and reliability of the electrical enclosures or cabinets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flat Bar High Quality Steel Flat Bar,Flat Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords