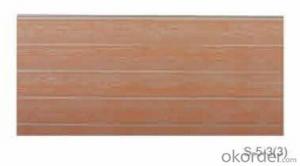

Fiber Cement board for villas,high building-013

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q:What is the kind of plate?

- Light weight: the use of the United States rock cement board for the wall, the weight of only the same thickness of the brick wall 1/15, block the wall of the 1/10, is conducive to structural seismic, and can effectively reduce the basic and structural cost.

- Q:more upscale. is this true? is there a big difference in the look? how do they differ in appearance? whats so great about it?

- vinyl siding is a 90% maintenance free product that is on the lower end of the spectrum in regards to cost, durability, and appearance. Fiber cement is costly, heavy but very durable, needs to be painted, but will last virtually forever.

- Q:I'm installing a new bathtub, can I attach the tub to the cement board?

- Yes, they did this on Blue Peter last year from velcro, a washing-up liquid bottle, and some sticky-backed plastic - remember when you're using the scissors to ask an adult to help!

- Q:nothing to add...

- Sure. It may react a little differently because of the moisture absorbing properties of the cement board. Try some tests and experiment with moistening the cement board before applying the texture.

- Q:I have a 5x20 room off my basement which sits under my front porch. All four walls of the room are cement block all the way up to the ceiling which is the cement slab from the porch above. There is a wood ceiling in the room that has gotten wet from leaks above. Is it safe to remove the wood joists and plywood in that room, fix the leaks and replace it? This doesn't support any weight from the slab above, does it? I assume that it was probably used as the bottom of the form when the slab was poured. Also, when I replace the ceiling, can I attach the ledger board using concrete sleeve anchors? Can these be fastened into the block wall? I'm not sure if they are hollow or have been filled with gravel or concrete. I plan on using the ledger board to fasten joist hanger to and frame back up my ceiling for insulation and wiring. The current ledger is attached with masonry nails. Any thoughts?

- Your ceiling may very well be no more than the bottom forms for the slab, but you really need to make sure. Attempting to seal the concrete slab from the underside isn't advisable. Concrete draws moisture, so you will always have a seepage problem after you're finished. I'd suggest sealing the slab on the surface and make sure it quit weeping before proceeding with the remainder of your project. Not all concrete blocks are filled. To secure your ledger board I'd suggest using a lag bolt with a lead spread type toggle. Drill into the block and insert to lead, which will hold the lag bolt. Hope this has been some help. Good Luck

- Q:I have an existing hardwood floor that I want to tile over (it's not in good condition). Can I put cement board then tile directly onto the hardwoods or do I need plywood on the hardwoods then cement board then tile? I don't want the floors to be 2 thick in addition to the hardwoods.

- Can you explain better? What do you mean when you say the hardwood is not in good condition? Uneven?Decaying?Quick answer if the hardwood is either, youre better off taking it out and starting with a good base.

- Q:What is the process of using a cement pressure plate to dry the tile? What do I need to know about the specifications of the light steel keel, how thick the board

- Process: the traditional, inconvenient practice is to use the steel wire hanging and then wiping the cement leveling, and then use the wet paste tiles. My advice is to use tile adhesive paste directly tile, fast efficiency, and after the process of ditch groove beautiful, unlike the cement paste the black seam.

- Q:How to fix the cracks in the ceiling

- The floor part of the ride will be 15cm wide leveling layer chisel, in the structure of the board surface along the cracks into the mouth about 2cm wide V-shaped section of the incision, the parts clean, after the use of epoxy resin to fill the plate flat , Ride sticky sticky 10cm wide paste carbon fiber, and then re-leveling layer will be poured, surface layer of light.

- Q:I need to know if hardibacker board is as good as other cement boards for use behind a tiled shower wall.?

- Yup! Hardibacker is what you want for a shower but do NOT use mastic as a tile adhesive. Go for thinset - it's lasts longer and doesn't have the history of cracking like most old shower walls do. They're virtually identical in application and handling but not longevity.

- Q:I just completely gutted my bathroom down to the wall studs and original plywood sub-floor. Which do I install first -- the new bathtub or the cement backer board on the floor? The original tile floor was over an inch thick. The new tub will be fiberglass, and I plan to put ceramic tile around the tub area as well as the main floor.

- If you got the standard enamelled metal tub you will see that the top edge may have screw holes already in it. I don't think fiberglass was much different- maybe no holes and you have to drill them yourself as the tub is in place This is screwed to the studs. Can't see studs behind cement board.(Don't care if you have better than 20:20 vision) CB is just a board for tiling onto. Before that was Greenboard basically gypsum board with a waterproof coating. Before that it was just gypsum board. The Tile& grout is the waterproof layer. Many houses were done on gypsum board. Mine has been done that way because neither Greenboard or Cementboard were not invented yet. Mine has been up for 35 years not a problem at all.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement board for villas,high building-013

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords