factory price!!! Galvanized/PVC Coated Welded Wire Mesh Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Factory price!!! galvanized/pvc coated Welded Wire Mesh Panel

1. Welded Wire Mesh Description:

Welded wire mesh is made from stainless steel wire or galvanized wire,which shows good corrosion-resistance and oxidation-resistance,widely used for poultry houses,egg baskets,runway enclosures,draining racks,porch guards,rat-proofing, safety guards on machines, animal and plant pens and shelves, etc.

2.Main Features of the Welded Wire Mesh:

smooth mesh surface ,well-proportioned meshes ,strong welded points and bright luster .The mesh doesn’t come loose even if cut in parts or being exerted force on parts .Compared with general iron wire ,the products are better in respects of anti-corrosive and anti-rust.

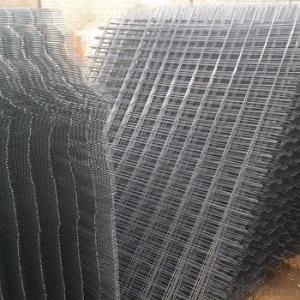

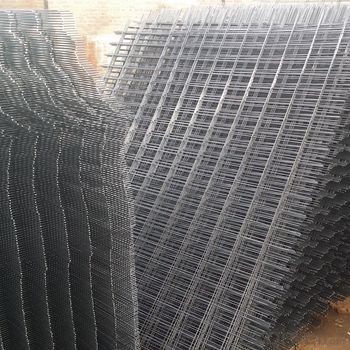

3.Welded Wire Mesh Images

4.Welded Wire Mesh Specification

Specification List of Galvanized Welded Wire Mesh: | ||

Opening | Wire Diameter | |

In inch | In metric unit(mm) | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22,23,24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19,20,21,22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16,17,18,19,20,21,22,23 |

5/8" x 5/8" | 16mm x 16mm | 18,19,20,21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16,17,18,19,20,21 |

1" x 1/2" | 25.4mm x 12.7mm | 16,17,18,19,20,21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14,15,16,17,18,19 |

1" x 2" | 25.4mm x 50.8mm | 14,15,16 |

2" x 2" | 50.8mm x 50.8mm | 12,13,14,15,16 |

Technical Note: 1.Standard roll length: 30m;width: 0.5m to 1.8m 2.Special sizes available at request | ||

Special sizes are also available.

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Australia.

(2)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:How is steel used in the production of HVAC systems?

- Steel is commonly used in the production of HVAC systems due to its strength, durability, and heat-resistant properties. It is used for manufacturing the framework, ductwork, and various components of the system, ensuring stability, longevity, and efficient functioning.

- Q:What are the properties of weather-resistant steel?

- Weather-resistant steel, also known as corten steel, possesses unique properties that make it highly resistant to corrosion from the effects of weather and atmospheric conditions. These properties include a high tensile strength, which allows the steel to withstand extreme weather conditions without losing its structural integrity. Additionally, weather-resistant steel forms a protective oxide layer on its surface when exposed to the atmosphere, preventing further corrosion and reducing the need for maintenance. Its durability, resistance to atmospheric corrosion, and aesthetic appeal make weather-resistant steel a popular choice for outdoor structures such as bridges, buildings, and sculptures.

- Q:How can steel products be protected from corrosion?

- Steel products can be protected from corrosion through various methods such as applying protective coatings like paint or zinc, using galvanization or electroplating techniques, implementing cathodic protection, or utilizing corrosion inhibitors.

- Q:How is steel pipe coated for corrosion resistance?

- Steel pipe can be coated for corrosion resistance through various methods such as galvanization, epoxy coating, or fusion-bonded epoxy coating. Galvanization involves applying a layer of zinc to the steel surface, forming a protective barrier against corrosion. Epoxy coating involves applying a layer of epoxy resin to the pipe surface, providing a durable barrier against corrosion. Fusion-bonded epoxy coating involves applying a powder coating to the heated pipe surface, which then melts and fuses to form a corrosion-resistant layer. These coating methods help protect steel pipes from the damaging effects of corrosion, extending their lifespan and maintaining their structural integrity.

- Q:How are steel tubes used in plumbing and HVAC systems?

- Steel tubes are commonly used in plumbing and HVAC systems due to their strength, durability, and resistance to corrosion. In plumbing, they are used to transport water, gas, and other fluids from one point to another. In HVAC systems, steel tubes are utilized for the distribution of air, refrigerants, and other gases. Their ability to withstand high pressure and temperature makes them a reliable choice for these applications. Additionally, steel tubes are often preferred for their ease of installation and maintenance, ensuring efficient functioning of plumbing and HVAC systems.

- Q:How is steel wire used in the production of springs for automobiles?

- Steel wire is commonly used in the production of springs for automobiles due to its high strength and flexibility. The wire is shaped and coiled to create various types of springs, such as suspension springs or coil springs, which provide stability, support, and absorb shock in a vehicle's suspension system. The durability and resilience of steel wire make it ideal for withstanding the constant compression and expansion required in automotive springs, ensuring a smooth and comfortable ride.

- Q:How are steel products used in the construction of shopping malls and retail centers?

- Steel products are extensively used in the construction of shopping malls and retail centers due to their strength, durability, and versatility. They are commonly used in the structural framework of the buildings, including beams, columns, and trusses, providing support and stability. Steel is also utilized in roofing systems, wall panels, and facades, ensuring the safety and aesthetic appeal of these structures. Additionally, steel is employed in the fabrication of escalators, stairs, and elevators, enhancing the functionality and accessibility of these commercial spaces. Overall, steel products play a crucial role in the construction of shopping malls and retail centers, contributing to their structural integrity and visual appeal.

- Q:What are the different types of steel fasteners and their uses in machinery?

- There are several types of steel fasteners commonly used in machinery. These include bolts, screws, nuts, washers, and rivets. Bolts are threaded fasteners used to join two or more parts together and provide a strong and secure connection. Screws are similar to bolts but have a different head shape and are often used to hold components in place or to create threaded holes. Nuts are used in conjunction with bolts to secure them in place. Washers are flat, thin discs placed between the nut and the surface of the material being fastened to distribute the load and prevent damage. Rivets are used to permanently join two or more materials together by deforming the ends of the rivet to create a secure connection. Each of these steel fasteners plays a vital role in machinery, ensuring structural integrity, enabling disassembly and reassembly, and providing efficient and reliable operation.

- Q:What are the different types of steel products used in the manufacturing of tools and machinery?

- Some of the different types of steel products used in the manufacturing of tools and machinery include carbon steel, alloy steel, stainless steel, and tool steel. Carbon steel is commonly used for general-purpose tools due to its durability and affordability. Alloy steel is a blend of carbon steel and other elements, providing enhanced strength, hardness, and resistance to wear and tear. Stainless steel is known for its corrosion resistance, making it suitable for tools and machinery exposed to moisture or chemicals. Tool steel is specifically designed for the production of cutting tools, molds, and dies, offering high hardness, heat resistance, and wear resistance.

- Q:What are the different types of steel profiles used in machinery frames?

- There are several types of steel profiles commonly used in machinery frames. Some of the most common ones include I-beams, H-beams, and C-channels. These profiles are chosen based on their strength, rigidity, and ability to support heavy loads. Each profile has its own unique properties and is selected based on the specific requirements of the machinery frame.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

factory price!!! Galvanized/PVC Coated Welded Wire Mesh Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords