embedded scraper transporter link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

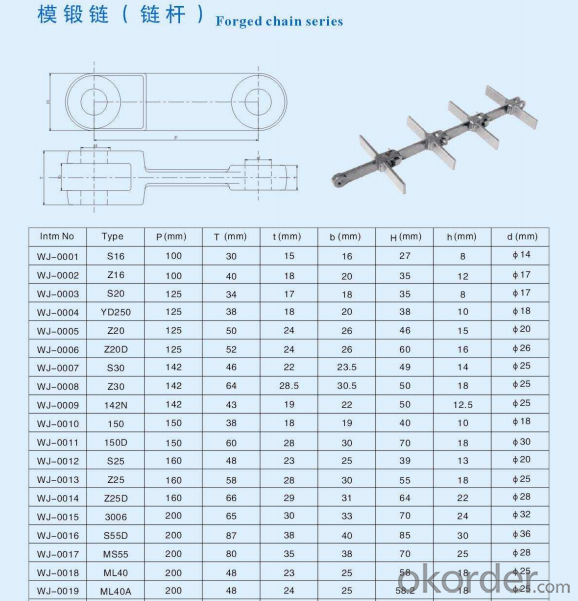

I beam overhead conveyor drop forged scraper chain link

I beam drop forged scraper chain link for overhead conveyor

1.Fine drop forging

2.With or without Zinc plated

F10190 ISO standard 150.0 pitch high tensile drop conveyor forging scraper chain

1.link 15.0mm

2.pitch 120.0mm

- Q:Why is the material advanced air cold and water cooling in the design of the device

- Hello, it is usually first to cool the medium to 100 degrees below and then to the water cooling. Mainly out of consideration the following factors: 1, air cooling is suitable for lower temperature, but the final temperature of the environmental impact is too big, can't accurate temperature will be reduced to a point, but water can be done.

- Q:How is the information flow of the material handling system implemented?

- Your topic is very large. High-end information-based software, such as the MES plus near-field recognition system (such as a credit card);

- Q:How is it based on the characteristics of various handling systems

- How are you The various elements of the moving material should be considered in the choice of handling equipment including the moving and method used

- Q:Ask for material handling robot design report

- Now on the college students of the experiment, you block him, at the gate of the laboratory to borrowed his experiment teaching material, were asked about the content of this course, as long as it is accurate, detailed, they not answer, he was dazed, asked the teacher is also a gaping; If he were to make the lab equipment, it would be eight, dead and dead. Now the school teaching equipment is procured from the society, the original manuscript of the experimental handout is provided by the teaching instrument supplier, the other can be imagined. To graduate, is the original abroad under the guidance of scientific literature and database import software systems, hardware platform, market procurement module and application-specific integrated circuit and components of the system integration, fast food science and technology, modern technology large platter

- Q:The parameters of the powder materials transport vehicle

- (12295 Kg) top speed: 12295 (km/h) emission standards: GB3847-2005, GB17691-2005 countries Ⅲ vehicle description: transportation item description: powder coal, density: 0.78 t/m3, the effective volume of tank: 24.88 cubic meters, the shape of tank size (length/diameter) of tank (mm) : 7200/2320, including tanks straight segment length is 6600 mm; When the chassis is 1560mm, the corresponding car is 1440mm, and the rear suspension of the chassis is 1325mm and the corresponding car is 1675mm. Protective materials: Q235 carbon steel, connection mode: left and right side and bottom protection are connected by welding, the back of the protective section size (mm) : 100 * 50 * 5, the back of the protective ground height (mm) : 540.

- Q:There is no quarterly material transfer label. How do you analyze it in 5

- The horizontal distance from the outside edge of the elevator platform and the unloading platform should not be greater than that

- Q:What is the difference between the requirements check function and the anti-check material list

- Visible, as long as good management independent requirements (sales product requirements), all the rest of the material requirements planning can be according to the product structure or material list according to the MRP operation logic. Bom is the indispensable important information management system of manufacturing management files, if the lack of MRP software support, it's difficult to build complex product bom. This means that advanced management ideas and methods require the support of information technology. ?? Material requirement management of the three main treatment process according to the thought of supply chain management, demand management is a kind of system management, sum up three process, namely: understanding requirements, access requirements, assurance requirements. The first two processes are primarily processing "independent requirements"; The latter process mainly deals with "related requirements". The three processes are intrinsically linked, and both require the support of the information technology.

- Q:What needs to be paid for forklift? How to determine the pros and cons of a forklift?

- ?domestic forklift have nearly 50 years of production history is today's quality level and so on have never heard of the brand, must study its strength and background, to make a decision. In the long run, don't focus on the immediate benefits. Now it may be saving some, and it may cost more in the future. 10, if you are still hesitating, please make the manufacturing process (especially the processing level of the details) as the final choice. 11, for no agency shop or individual to be very careful to recommend the brand, because they are usually in accordance with the principle of benefit maximization as well as the relationship with forklift agents to choose, and not recommend to you the price the best brands items

- Q:What are the components of an automated three-dimensional warehouse?

- The third stage is the automation of the warehousing technology phase, and the automation technology plays an important role in facilitating warehousing technology and development. In the late 1950s and 60s, automatic pilot car (AVG), automatic shelf, automatic access robot, automatic identification and automatic sorting system were adopted. In the 70 s and 80 s, rotate style shelves, mobile racking, roadway type stacker and other handling equipment joined automatic control, but at this moment is only partial automation of all equipments and application independently, known as the "islands automation". Along with the development of computer technology, the focus turned to material control and management, real-time, coordination and integration, computer, data between patch, mechanical equipment controller and communication between host computer and they can timely summary, warehouse computer record orders in a timely manner and the delivery time, according to inventory, supply planners can easily make a decision, they know what is the production and book what goods, what time to send what goods, management personnel to understand the supply and demand. The application of information technology has become an important pillar of warehouse technology.

- Q:The stability of material lift machine mainly depends on which parts of the material hoist

- It mainly depends on the transmission system and hydraulic braking system or mechanical braking system

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

embedded scraper transporter link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords