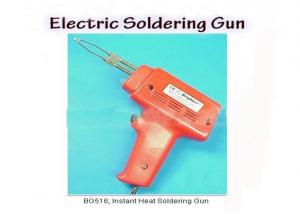

Electric Soldering Gun SG106

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Electric Soldering Gun, SG106

> Voltage: 110V or 220V

> Power: 100W,

> Cord: GB or A plug

> Packed in printed box

> Durable, Dependable

We are a direct manufacturer of electrical tools with experience of more than 25+ years. With our well experience and the stricted quality control, our company has become famous in many markets over the world.

Agents or distributors wanted. OEM is welcome!!

Our annual production quantity is two millions pieces for assorted models.

- Q:What about the power line of the electric iron being burned to a little?

- General electric iron is a dual core or three core cable if Tanghuai no exposed metal core wire inside so you can continue to use, if hot or deep so the exposed core wire with insulating tape and then wrapped the parting line. Or you can change the power cord directly

- Q:How the LED lamp patch welded to the PCB plug-in board (except the ordinary electric iron is too slow and I mass) with what method or welding tool

- Solder patch components, ready to solder paste, buy a box of solder paste. Then buy a 5 ml syringe and add the solder paste. Change into a 0.8-1.2MM needle. Now, point the solder joints on the solder paste. After the point is good, place the patch element on the solder joint. It doesn't need to be neatly placed. When welding, it will be automatically aligned because of the tension of the solder. All right, with off, up to 255 degrees, each blow welding components. Don't think too fast, include a baking time! Practice first and learn quickly

- Q:Is there any way to solder a copper block to a small wire with an electric iron, and each soldering does not stick?,

- Glue it first and then solder it

- Q:It's going to buy an electric iron for wires and some small parts on the electric board in Taobao. Being a beginner, it is purely amateur. I do not know how many tiles to buy, but it is best to dissolve tin hot fast. Internal heat and external heat, pointed flat mouth. Which is more suitable for welding small objects (such as sockets, loose welding, stable points, etc.)? How many watts can both dissolve quickly and not hurt small pieces?

- Hardware stores have sold, 50W, just fine, more than 20 yuan will be able to buy good.

- Q:What's the number of electric irons? See 30W, 40W, 60 watts, I usually get small appliances

- With the straight pointed 35W just right

- Q:I want to get a shelf for fixing the electric iron, that is, fix the iron to the top so that the components are quick

- It is recommended to try the plug type seat. The ceramic is resistant to temperature and the screw hole is well inserted. The iron head can be chosen according to the size of the iron head. It is estimated that more than 15A can be done.

- Q:Mp3 interface is broken, so that the master electric soldering iron melted a lot of tin welding, found that Mp3 can only be detected after connecting the computer, and then will be lost. Previously there is a U disk is also, the former plug in the computer will be lost, and then plug no problem, because the voltage caused by low. So I suspect this is caused by an increase in the resistance of the interface.The tin that melts can be washed off in heating, how to avoid burning the electric circuit when welding?Master pointing

- It is impossible to increase the resistance at the ohm levelWelding must be guaranteed below 270 degreesAnd do not solder short circuits

- Q:How much is the temperature of the electric iron? How much watts is good?I use 25W pointed electric soldering iron solder on the graphics capacitor, half a day can not solder down, but also for a long time, the video card to burnIs that tin impure or is my soldering temperature too hot?Tin will melt soon. I wonder why a capacitor doesn't weld

- Circuit board, integrated circuit this is best to use DC iron belt, reliable grounding.25W is still pointed, and the 60W is too small. I use 500W constant temperature DC soldering iron.The iron temperature is not enough temperature to 380-410 degrees, because the iron head is small, the heat transfer is slow, that is to say in unit time passes in the heat of melting solder is not a long time, the local temperature will rise so high power short iron.If it were me, I would use 1.25mm's iron head 450 degrees, solder a small amount of soldering iron, and then go to the capacitor solder joints; a small amount of solder to increase the contact area with solder joints to speed up heat transfer.

- Q:Can the electric iron of the school solder aluminium products?

- The welding of aluminium alloys with iron can be made in the case that the aluminum matrix must be very fine, or that aluminum is very thin film. But as long as there is a general aluminum structure and size of certain words, suggestion is to use liquefied petroleum gas porous WE53 special welding gun, and then with a low temperature aluminum welding.That is if you want to weld aluminum is aluminum foil, thin aluminum and other small and thin pieces, can be used for welding or soldering iron, hot air gun, but low wire materials need to use M51 with M51-F flux.Process for soldering electric iron1, the electric iron inserted into the electric heating.2. Adjust the pin of the capacitor and insert it into the printed circuit board3. Apply a small amount of solder paste on the contact between the capacitor pin and the circuit board.4. The iron head of the preheated electric iron is pressed at the contact point between the pin and the circuit board for a moment, so that the local temperature is increased to the melting point of tin wire. The solder wire to the pin contact with the iron head, when the appropriate amount of solder, solder wire removed along the pin element, remove the iron, solder joint into a round.5, diagonal pliers to cut unnecessary stitches, complete the soldering operation. Tip: right between the residence time and the operation steps of soldering a great influence on the welding quality, need to gradually learn in practice.

- Q:How do I remove the whole part from the circuit board? How about the electric iron?

- A small amount of stitch (below 3 pins) is available with a soldering ironA large number of words, the electric stove top plate, pay attention to temperature, insulation, circuit board pads placed side down on the plate, such as melting solder tweezers to remove components, circuit board or flip off elementSMD components available hot air gun

We have been a specialist in the manufacturing of electrical appliances, tools and printer cartridges. Most of our products have been test-certified and proved to comply with renowned safety standards, such as UL and CE. With a labour force of more than 100 workers and our excellent production facility, our success is reflected by our sales volume of HKD50 million every year.

We have a wide variety of products: Handy Steamers,Glue Guns, Soldering Tools ,BRIFLON Heat Resistance Adhesive Tapes ,Printer Toner Cartridges

1. Manufacturer Overview |

|

|---|---|

| Location | Kowloon, Hong Kong |

| Year Established | 1971 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electric Soldering Gun SG106

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords