E-glass Chopped Strand Mat 3200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

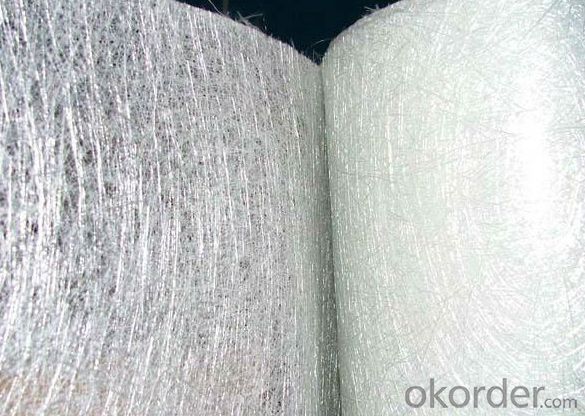

Chopped strand mat with width 3200mm

2.Main Features

Our chopped strand mat is with width 3200mm, packing in wooden box (pallet)with width 3250mm. In each 40HQ can be loaded 16-18 boxes(pallets), qualitu is around 2000kgs in each container.

Standard Specifications for Chopped strand mat

1. High quality

2. ISO9001, 2008 quality controled

3. 320cm width, 100g,300g,450gto 900g

Our chopped strand mat factory specializes in manufacturing E-glass Chopped strand Mat (chopped strand mat manufacturer). The products range from chopped strand mat 300g/m2, chopped strand mat 450g/m2 to chopped strand mat 600g/m2 and 900g, the width from 102cm,104cm,125cm to 320cm.

3.Specifications

Product code | Glass type | Unite weight (g/m2) | Width(mm) | Roll weight (kg) | Moisture (%) | Binder content (%) |

100 | E Glass | 100+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

150 | E Glass | 150+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

200 | E Glass | 200+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

300 | E Glass | 300+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

| 450 | E Glass | 450+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

600 | E Glass | 600+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

900 | E Glass | 900+/-20 | 200-3200 | 30-70 | <0.2-0.3 | 3-4 |

4.FAQ

Q: Which knid of payment terms can you accept?

A: We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q:Can fiberglass mat tissue be used for repairing fiberglass kayaks?

- Yes, fiberglass mat tissue can be used for repairing fiberglass kayaks. It is commonly used as a reinforcement material in fiberglass repairs due to its strength and ability to conform to curved surfaces.

- Q:Can fiberglass mat tissue be used for making lightweight countertops?

- Yes, fiberglass mat tissue can be used for making lightweight countertops. Fiberglass mat tissue is a thin, lightweight material made from fine glass fibers, which makes it an ideal choice for creating lightweight countertops. It provides strength and durability while also being easy to work with and mold into various shapes and sizes. Additionally, fiberglass mat tissue is resistant to moisture, chemicals, and heat, making it a suitable material for countertops that may be exposed to these elements. Overall, using fiberglass mat tissue for making lightweight countertops is a practical and efficient solution.

- Q:What is fiberglass mat tissue?

- Fiberglass mat tissue is a type of non-woven material made from glass fibers that are randomly oriented and bonded together with a binder. It is commonly used in various industries, including construction, automotive, and aerospace. The main purpose of fiberglass mat tissue is to provide strength, durability, and reinforcement to composite materials. It acts as a supporting layer between the resin and the glass fibers, helping to distribute stress and improve the overall mechanical properties of the final product. Fiberglass mat tissue has several advantages over other materials. It is lightweight, flexible, and easy to handle, making it ideal for applications that require complex shapes or curved surfaces. It also has excellent resistance to chemicals, moisture, and temperature changes, ensuring its longevity in harsh environments. In construction, fiberglass mat tissue is often used in the production of roofing materials, wall panels, and insulation boards. Its high strength-to-weight ratio makes it a popular choice for reinforcing concrete structures, such as bridges and buildings. In the automotive industry, fiberglass mat tissue is used in the manufacturing of car parts, such as body panels, bumpers, and interior components. It can enhance the structural integrity of these parts, making them more resistant to impacts and vibrations. In the aerospace industry, fiberglass mat tissue is employed in the production of aircraft components, such as wings, fuselages, and interiors. Its lightweight nature contributes to fuel efficiency and overall weight reduction, while still maintaining the necessary strength for safe flight. Overall, fiberglass mat tissue is a versatile and reliable material that plays a crucial role in enhancing the performance, durability, and safety of various products in different industries. Its unique properties make it an indispensable component in the production of composite materials.

- Q:What are the advantages of using fiberglass mat tissue in construction?

- There are several advantages to using fiberglass mat tissue in construction. Firstly, fiberglass mat tissue provides excellent reinforcement and strength to various construction materials. It enhances the structural integrity and durability of the final product, making it resistant to cracks, impacts, and weathering. This makes fiberglass mat tissue an ideal choice for reinforcing concrete, roofing materials, and composite products. Secondly, fiberglass mat tissue is lightweight and easy to handle, making it convenient to work with during construction. Unlike traditional reinforcement materials like steel, which can be heavy and require specialized tools for installation, fiberglass mat tissue is easily cut, shaped, and applied. This reduces the labor and time required for construction, leading to cost savings. Additionally, fiberglass mat tissue is non-corrosive and non-conductive, making it suitable for use in a wide range of environments. It does not rust or degrade over time, even in harsh conditions, ensuring the longevity and reliability of the construction. Moreover, fiberglass mat tissue does not conduct electricity, making it a safe choice for applications where electrical conductivity needs to be avoided. Furthermore, fiberglass mat tissue offers excellent thermal insulation properties. It acts as a barrier to heat transfer, helping to maintain a comfortable and energy-efficient interior environment. This can lead to reduced heating and cooling costs in buildings, making fiberglass mat tissue a sustainable and cost-effective option. Lastly, fiberglass mat tissue is resistant to fire and chemicals. It does not burn or release toxic fumes when exposed to flames, providing an added level of safety in construction. Additionally, it is resistant to many chemicals, including acids and alkalis, making it suitable for use in corrosive environments such as chemical plants or industrial facilities. Overall, the advantages of using fiberglass mat tissue in construction include enhanced reinforcement, lightweight and easy handling, non-corrosive and non-conductive properties, thermal insulation, fire resistance, and chemical resistance. These benefits make it a versatile and reliable material for various construction applications.

- Q:How does fiberglass mat tissue compare to fiberglass insulation batts?

- Fiberglass mat tissue and fiberglass insulation batts differ in composition, purpose, and usage. Fiberglass mat tissue, also known as fiberglass veil or fiberglass veil mat, consists of fine glass fibers woven into a thin fabric. It is primarily used to reinforce composites like roofing materials, laminates, and automotive parts, providing strength, durability, and resistance to cracking or tearing. This material is commonly employed in applications that require high tensile strength and dimensional stability. On the contrary, fiberglass insulation batts are thick, flexible panels made from compressed fiberglass fibers. These batts are specifically designed for thermal insulation and are commonly used in residential and commercial buildings. Their main function is to create a thermal barrier, improving energy efficiency by reducing heat transfer. Fiberglass insulation batts are typically installed in walls, attics, or crawl spaces to minimize heat loss or gain, resulting in better temperature control and reduced energy costs. It is essential to note the distinct purposes and applications of fiberglass mat tissue and fiberglass insulation batts when comparing them. Fiberglass mat tissue should not be used as a substitute for insulation batts, as it is not intended for thermal insulation. Conversely, fiberglass insulation batts are not suitable for use as a reinforcement material in composites. Regarding construction and installation, fiberglass mat tissue is commonly used in combination with other materials, such as resins or adhesives, to create a composite structure. It is easily cut, shaped, and molded to fit various shapes and sizes. On the other hand, fiberglass insulation batts are available in pre-cut sizes and can be easily installed by fitting them between framing studs or joists. Both fiberglass mat tissue and fiberglass insulation batts have their advantages and disadvantages, depending on the specific project requirements. While fiberglass mat tissue offers superior strength and dimensional stability for composites, fiberglass insulation batts excel in providing thermal insulation for buildings. Ultimately, the choice between the two will depend on the intended application and desired outcome.

- Q:Is fiberglass mat tissue resistant to mold and mildew?

- Yes, fiberglass mat tissue is resistant to mold and mildew due to its non-porous and moisture-resistant properties.

- Q:What are the recommended storage and handling practices for fiberglass mat tissue?

- When it comes to the storage and handling of fiberglass mat tissue, there are a few recommended practices that should be followed to ensure its integrity and longevity. 1. Storage: It is important to store fiberglass mat tissue in a clean and dry environment. This helps prevent any moisture or dirt from damaging the material. Ideally, it should be stored indoors away from direct sunlight and extreme temperatures. 2. Handling: Fiberglass mat tissue is a delicate material that can be easily damaged if not handled properly. It is recommended to wear protective gloves and safety glasses when handling it to prevent any injuries. Additionally, it should be handled with care to avoid any tears or creases that may compromise its performance. 3. Transportation: During transportation, it is crucial to pack fiberglass mat tissue in a way that minimizes the risk of damage. It should be securely packaged and protected from any potential impact or vibration. If possible, it is best to transport it in a dedicated vehicle or container to ensure its safety. 4. Avoid contact with chemicals: Fiberglass mat tissue should not come into contact with chemicals such as acids, alkalis, or solvents. These substances can cause degradation and weaken the material. It is important to handle it with clean hands and avoid any contact with substances that may be harmful. 5. Follow manufacturer's guidelines: It is always advisable to follow the specific recommendations provided by the manufacturer regarding the storage and handling of fiberglass mat tissue. Different manufacturers may have slightly different requirements, and it is important to adhere to them for optimal performance and longevity. By following these recommended storage and handling practices, you can ensure that fiberglass mat tissue remains in good condition, ready for its intended use.

- Q:Can fiberglass mat tissue be used for acoustic insulation?

- Yes, fiberglass mat tissue can be used for acoustic insulation. Fiberglass mat tissue is a lightweight material that has excellent sound absorption properties. It can effectively absorb and dampen sound waves, reducing noise and improving the acoustic environment. Fiberglass mat tissue is commonly used in the construction industry for insulating walls, ceilings, and floors to reduce noise transmission. It is also used in automotive applications and other industries where sound insulation is required. Its high porosity and fibrous structure make it an ideal material for absorbing and attenuating sound waves, making it suitable for acoustic insulation.

- Q:How is fiberglass mat tissue used in the production of composite panels?

- Fiberglass mat tissue is commonly used in the production of composite panels due to its unique properties and versatility. It serves as a reinforcement material that helps enhance the strength, durability, and overall performance of the composite panels. In the production process, fiberglass mat tissue is typically sandwiched between layers of resin to create a composite structure. The tissue acts as a reinforcing layer, providing additional strength and stability to the panels. It helps distribute the stress applied to the panel evenly, reducing the risk of cracks or fractures. One of the key advantages of using fiberglass mat tissue is its ability to improve the impact resistance of composite panels. The tissue absorbs and disperses energy when subjected to external forces, minimizing the risk of damage or breakage. This makes it an ideal choice for applications that require high impact resistance, such as automotive parts, boat hulls, or aircraft components. Fiberglass mat tissue also offers excellent corrosion resistance, making it suitable for use in environments with high humidity or exposure to chemicals. It acts as a barrier that protects the composite panels from moisture and corrosive substances, extending their lifespan and ensuring their long-term performance. Additionally, fiberglass mat tissue is highly moldable, allowing for the creation of complex shapes and designs. It can be easily molded into various forms, providing flexibility in the production process and enabling the creation of customized composite panels for specific applications. Overall, fiberglass mat tissue plays a crucial role in the production of composite panels by reinforcing the structure, enhancing impact resistance, improving corrosion resistance, and enabling flexibility in design. Its unique properties make it a popular choice in industries such as construction, transportation, aerospace, and marine, where high-performance and durable composite panels are required.

- Q:Can fiberglass mat tissue be used for insulating refrigeration units?

- Fiberglass mat tissue is indeed suitable for insulating refrigeration units due to its lightweight nature and outstanding thermal insulation properties. It finds extensive use in a wide range of applications where insulation is necessary, including refrigeration units. By minimizing heat transfer, the fiberglass mat tissue ensures that the internal temperature of the refrigeration unit remains stable, safeguarding the stored items from any external heat. Moreover, its moisture-resistant capabilities are particularly crucial in refrigeration units as they prevent condensation and help maintain the cooling system's efficiency. All in all, fiberglass mat tissue proves to be a reliable and effective option for insulating refrigeration units.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Chopped Strand Mat 3200mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords