Cutting and Transporting Equipment---Stacking Bricks Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

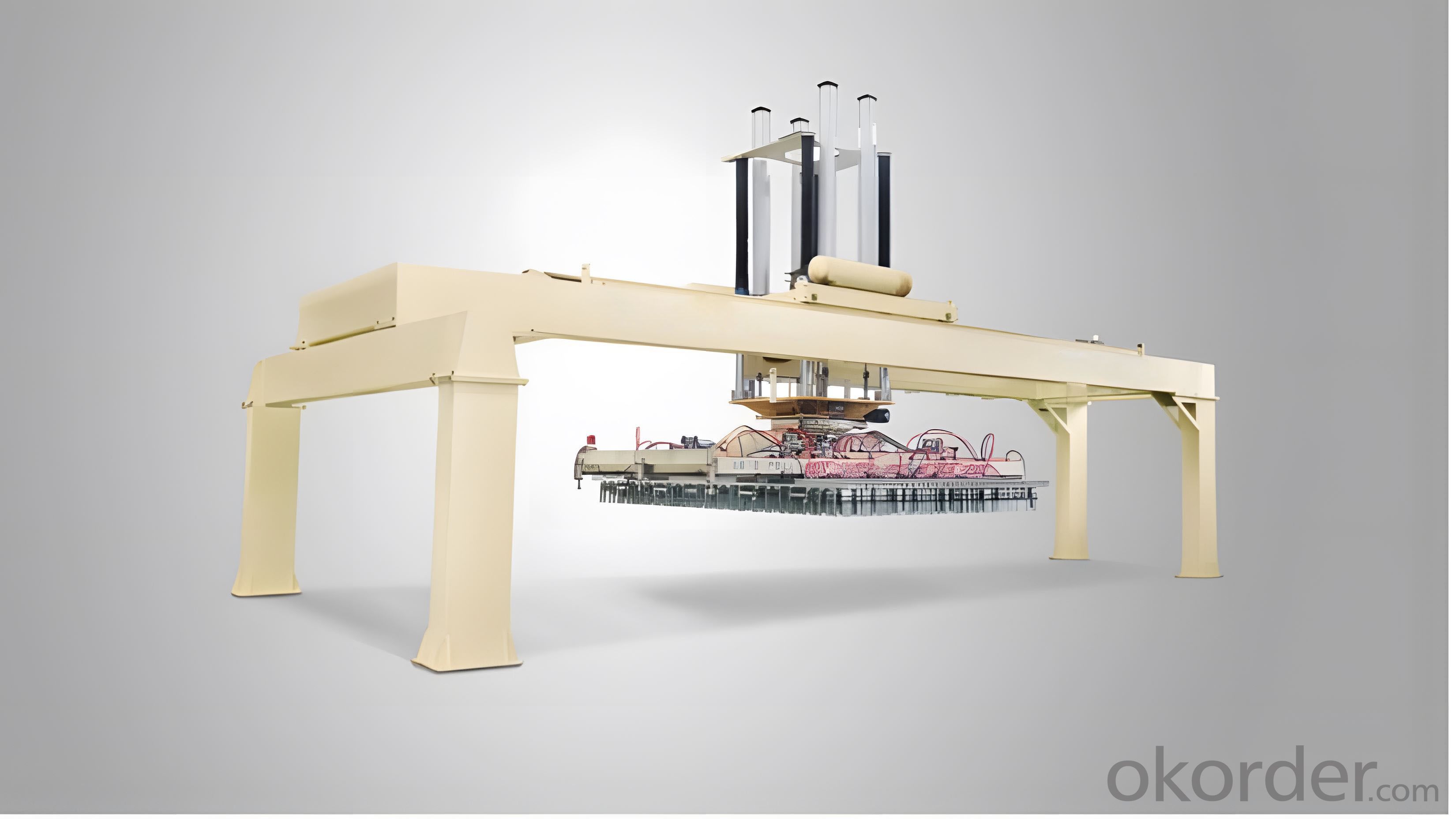

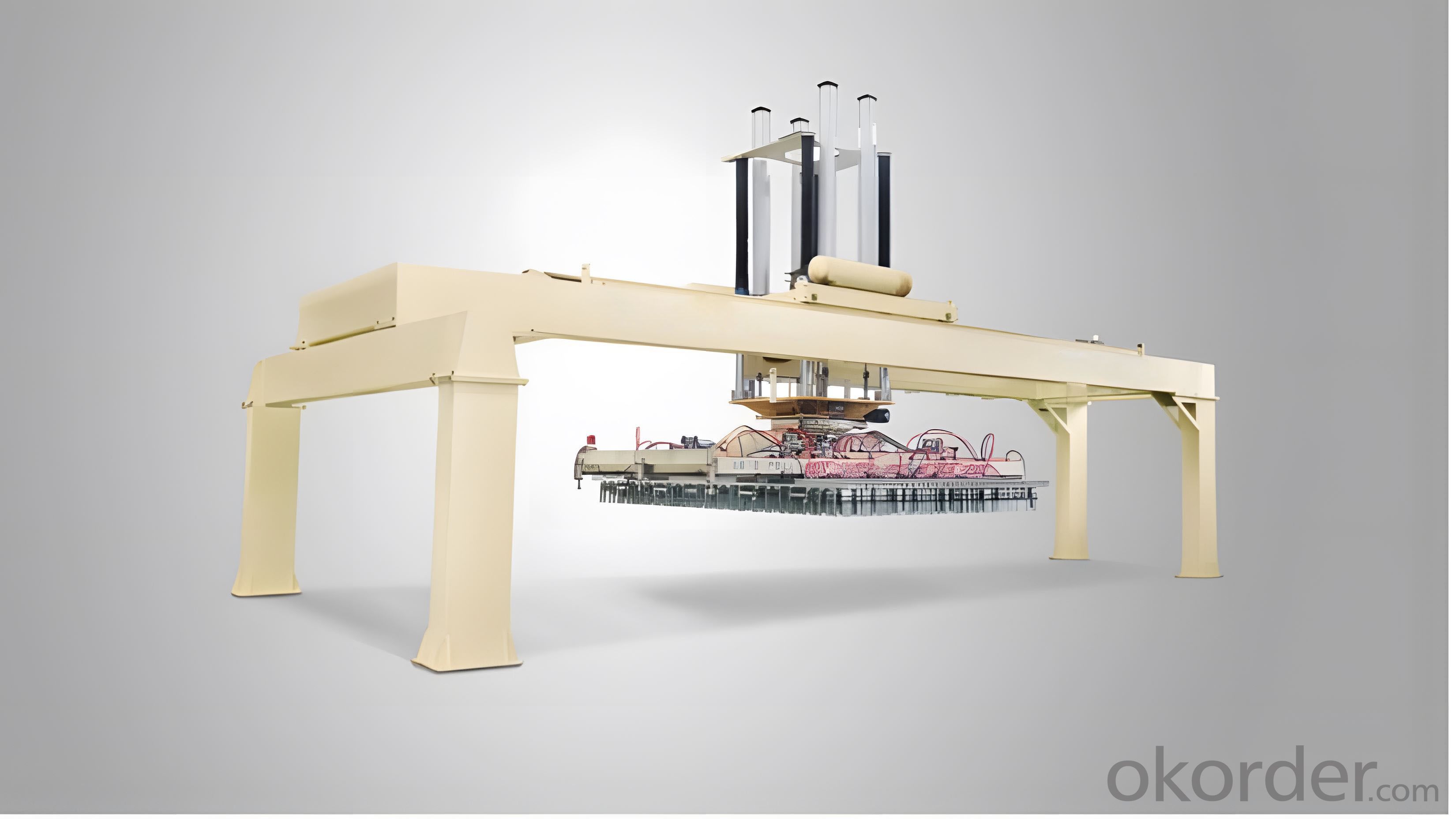

Picture1 and Picture2--Product performance:

Special press with single, double, and four-column. When changing brick types such as hollow bricks and thermal insulation blocks, the conversion of the bricks is convenient. The simple new powerful drive structure replaces the complex RV reducer to achieve a new height of load capacity and durability. It is suitable to produce multi-variety bricks and blocks and has the advantages of flexible brick conversion and low cost and can meet the medium and high output.

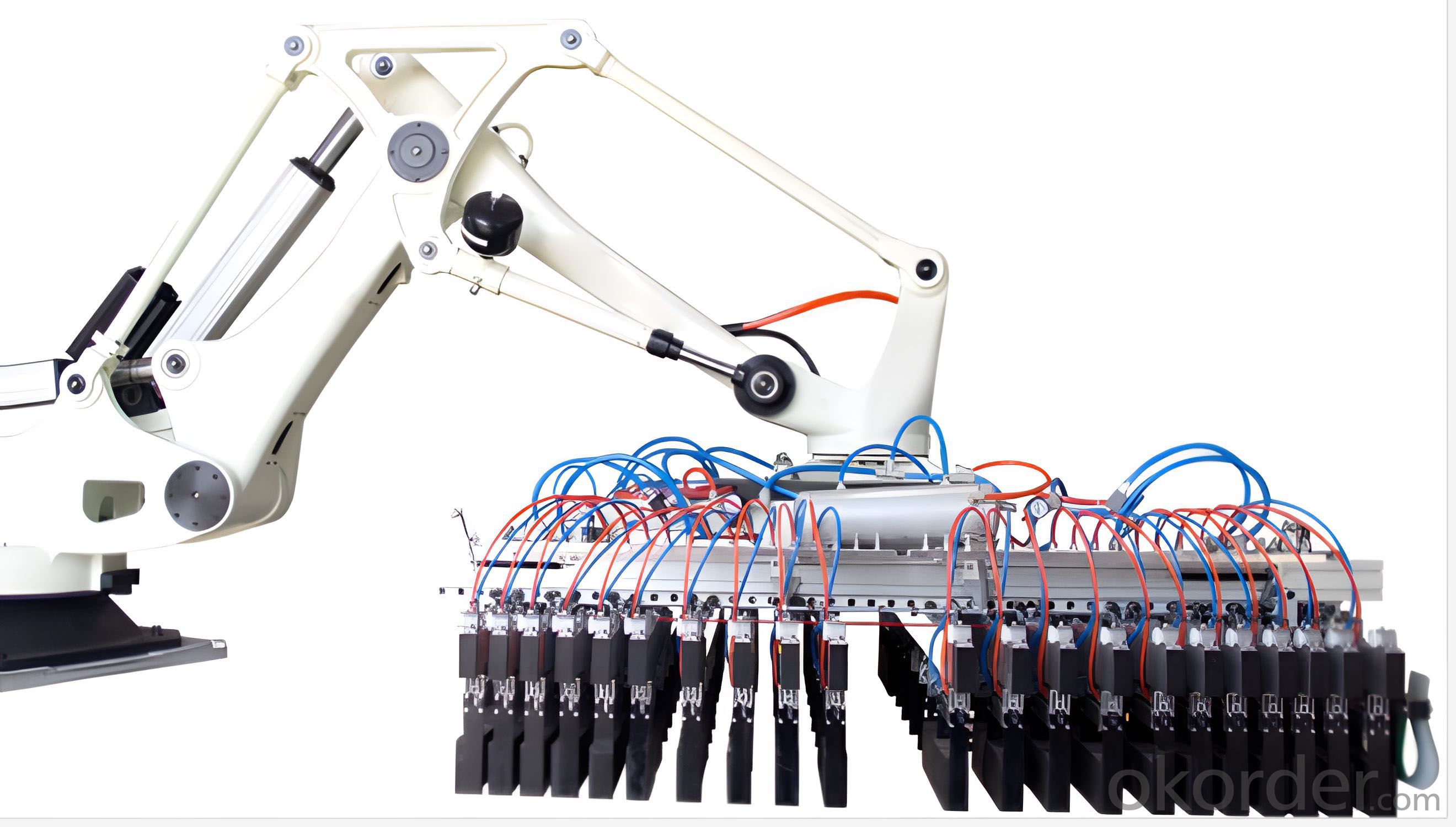

Item/Specification | ZWMR-1200 |

Structure | vertical articulation |

Flexibility | 4 |

load mass | 1200kg |

Dimensions | 3530x1000x2400mm |

Maximum working radius | 3520mm |

Repeatability | ±1mm |

Body weight | 1920kg |

Average power consumption | 11kw |

noise | 75bB |

Depending on the running attitude, some attitudes may not reach the maximum speed of each axis. | |

Picture2--Robotic hand stacks bricks

----------------------------------------------------------------------------------------------------------

Picture3--Stacking Bricks Machine

Product performance:

High-speed, high-efficiency, stable and reliable, simple operation, and convenient maintenance. It can operate a variety of brick types, change a set of chucks within 30 minutes, without affecting production; can operate long and short strips, arcs for the top layer, and compression gaps. The product has precise positioning, does not drop bricks, leak bricks, or break bricks; it has a high degree of intelligence and can realize unmanned control of the whole process; standardized spare parts design, easy maintenance, and low cost.

Parameters of Stacking Bricks Machine(Some models)

Models | Suitable for Kiln Type | Suitable for Section(m) | Capacity Per Hour (Common Brick) | Single Cycle Time(s) | Chuck |

ZWM2.2-2.8 series | Tunnel kiln, rotary kiln | 2.2-2.8 | 30 thousand | 28 | single |

ZWM3.0-4.3 series | 3.0-4.3 | 50 thousand | 36 | single | |

ZWM4.4-5.0 series | 4.4-5.0 | 60 thousand | 40 | single | |

Double chuck | 5.3 above | double |

- Q:Reconditions will do, will need some for places with dire needs

- The okorder /

- Q:How to improve the mechanical properties of materials?

- Shot peening can improve the surface tension of the material, improve the surface hardness, but also improve the ability to resist corrosion.

- Q:Please send me information about some company manufacturing this machinery. I have heard that some overseas companies are there.

- See: okorder

- Q:where can i get the plant layput & list of machinery along with market value?

- For what kind of company?

- Q:i want to buy from china

- through the service you just like engage a agent in China to help you to find what you need in China.

- Q:A. Counter revolutionB. DirectoryC.RevancheD.Thermidorean reaction

- D - Thermidorean Reaction.

- Q:green company purchased a piece of machinery on credit for 10,000.Briefly state how this transaction affect th?

- Green okorder

- Q:I'm a vegetarian who doesn't eat fish and I was just wondering what this means.

- If it's processed on the same machinery as, lets say nuts, the knife,grinder, or whatever the machine is was used on your food and nuts. They normally put this for allergy precaution

- Q:i need help w/ a science question lol....:] help please! thnx! o and also, the 1st question is more important, but if u know this one, it would help too: How is friction a factor in outer space?

- Motion is produced by some of the following: 1) rotating magnetic fields (electric motors) 2) explosions (internal combustion engine) 3) heat expansion of gas (steam engine, rockets) I am not sure about friction in outer space but I believe because there is no air or gases around joints and gears, friction would literally vacuum cement the sliding parts together. You would need to ensure that some sort of matter (gas, liquid) was present in order to allow parts to slide on top of each other.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cutting and Transporting Equipment---Stacking Bricks Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.