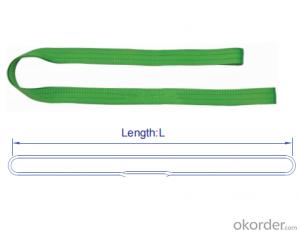

Color Capacity Polyester Pipeline Round Webbing Belt Lifting Sling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color Capacity Polyester Pipeline Round Webbing Belt Lifting Sling

Mainly used for pipes hoisting.

Raw material is Polyester fiber (PES).

It is wide and easy to keep balance during operation. The pipe surface is rough. We can handle the sling specially. The sling could be coated with a layer of rubber and then it will be anti-slip, high – temperature

– resistant and corrosion - resistant.

The sling can be used assembly with beam and metal parts. It has advantages such as safe and convenient construction, long service life, etc.

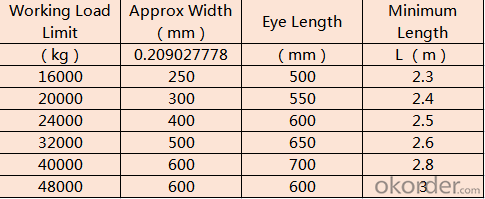

Note: 5:1 safety factor is available. The working load limit is corresponding to U-lifting method

Chracteristics:

Soft, light, no harm to the cargo, safety, long life and so on.

Light and soft, can be used in small narrow space.In PU processing, anti-abrasion is enhanced,Non-conductive, no danger of electric stroke.

Product usage :

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:1.210 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

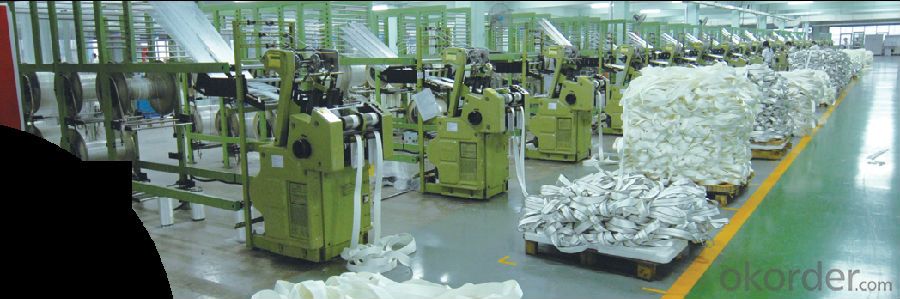

Textile sling factory is the largest base for lifting belts in the world with the production capacity "over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines "from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc. The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope "and traction rope, according to different using environments, different materials would be used, "such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene "material).

We are able to manufacture special slings such as high-strength type, flame retardant "type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant "type, fluorescent type, optical inspection type and oil and water resistant type sling. With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other "operations in machining, port handling, marine engineering, ship, electric power, transportation, "aerospace and other fields. Achievements in scientific research:In 1997, we drafted out the industrial standard for textile "slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic "progress for the Chinese textile sling industry. "In 2007, we revised JB/T8521.1-2007"Textile Sling – Safety - Part 1: Common use webbing "sling" and JB/T 8521.2-2007"Textile Sling - Safety - Part 2: Common use round sling". In 2009, we edited GB/T 23914.2-2009"Road vehicle mounted fixtures – Safety – part 2: "Synthetic ratchet strap assemblies", participated in writing TB/T 3123.11-2009"Rescue devices for "railway accidents - part 11: high-performance textile sling". In 2014, we participated in writing GB/T 30667-2014"Polyester and polyolefin dual Fiber rope "and GB/T 30668-2014"8 strands, 12 strands and multiflament braided Ultra high molecular weight "polyethylene fiber rope".

- Q:Do cranes have the same wire ropes, slings, slings and cables?

- To be exact, different things are very relevantThe cable belongs to the sling and belongs to the spreaderA wire rope can be made into a wire rope rigging

- Q:Slings and rigging manufacturers, which cost-effective?

- Wire rope rigging, manganese phosphating coating steel wire rope is a new technology appearing in recent years. Wire rope has a long service life. Buy wire rope made of phosphating coating steel wire,

- Q:Notice of tower crane?

- After the tower crane is installed, the whole machine should be inspected and adjusted, and shall be ready for delivery after passing the inspection in stages and through the whole machine. In the case of no load, the deviation of the verticality between the tower and the ground shall not exceed 4/1000.. The motor and hydraulic unit of the tower crane shall be carried out in accordance with the relevant provisions concerning the motor and hydraulic device.

- Q:How do you tie the wire rope?

- The price of phosphating coating wire rope is higher than that of smooth steel wire rope, but the unit use cost is lower than the smooth steel wire rope. The test data indicate that fatigue life of phosphating coating steel wire rope is 3-4 times of plain steel wire rope, wire rope life and fatigue life is proportional to, according to the current market price of roughly wire rope, manganese phosphating coating of steel wire rope although the price is higher than that of plain steel wire rope, and prolonging the service life of much higher than the rate of price increase so, the phosphating coating steel wire rope, the average daily cost of using only smooth steel wire rope 30-45%, longer service life, lower cost per use, stability and security in the process of using and more cost-effective products, light surface wire rope upgrade, for reference only

- Q:How to choose the right sling?

- The selection of rigging should be adapted to the kind of articles, environmental conditions and specific requirements.The sling to carry out strict inspection, in accordance with safety color to use, if found damaged sling can not be reused, need for scrap processing.The slings used for lifting operations must be of the same length.The sling shall not exceed its rated lifting capacity, and the sling shall not exceed its maximum safe working load.

- Q:What are the selection principles for lifting cranes?

- It can adapt to the conditions of road, hoisting, plane layout and equipment, machines and tools, and give full play to its technical performance.

- Q:Types of slings for slings

- Synthetic fiber slings are mainly made of nylon, polypropylene, polyester, high-strength and high modulus polyethylene fiber for rope and belt slings.

- Q:What is the line on the train for?

- It's called catenary. There are two lines up and down. The upper part is called the load line, and the lower one is called the contact line. There is a sling connection between the cord and the contact wire.

- Q:How much is the crane arm of the tower from the residential building recently?

- (1) the drivers and signaling personnel of the tower cranes must be specially trained and issued certificates by the relevant departments, and attention should be paid to whether the type of tower used by the driver is consistent with the actual tower type.(2) special person special plane management, Captain responsibility system, and strict shift shift system.(3) the newly installed or repaired tower crane must perform the machine test operation according to the specifications.(4) tower crane should keep a safe distance from overhead transmission lines.(5) driver's room should be equipped with fire extinguishing equipment.

- Q:Does the pressing rope have any influence on the tension value of the wire rope?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, up to 5 times, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Capacity Polyester Pipeline Round Webbing Belt Lifting Sling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches