0.25T Manual Chain Block HS-Z high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Place of Origin: Hebei, China (Mainland)

Brand Name: CNBM

Model Number: HSZ-0.25T

Usage: Construction Hoist

Power Source: Hand Chain

Sling Type: Chain

Maximum Lifting Weight: 0.375T

Maximum Lifting Height: 12m

Lift Speed: as your speed (MANUAL)

Certification: CE and GS

Warranty: one year

Capacity: 0.25t

Test load: 0.375t

color: red or as you require

certification: ISO9001and CE

Material: steel

load chain diameter: 4mm

the load chain: G80

n.w: 3.5kg

No of load chians: 1

Standard lif height: 2m

7) Chains are made of special alloy steel that is exclusively

8) More thickness of sheet cover,gear cover and side plates for good quality

9) The static test is 4 times of capacity,and running test is 1.5 times of capacity one by one

10) Famous in Europe and America

Main Features

•Severe environment and work condition are acceptable;

•Simple structure and few components

•Adopt Janpanese FEC chain;

•To greatly enhance the performance of the fatigue and wearresistance.

•Limit protection adevice can avoid overload occerring;

•Hook bolt can prevent the rigging accidently from slip;

•Moter is equipped with thermal protection device;

•limit contactors are set in the machine.

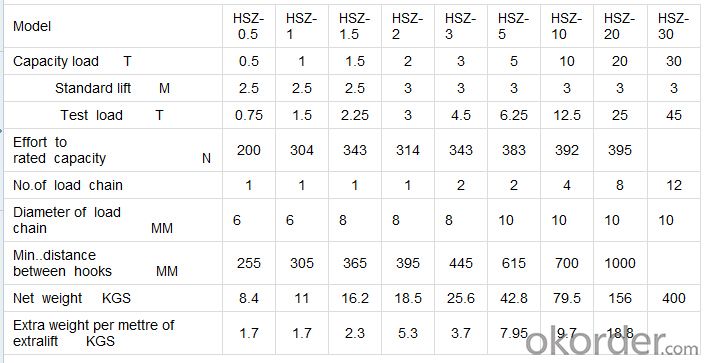

Parameter List

Service

1.We can make special sample according to the customer’s requirement.

2. We have more than 60 professional technical team, provide best after-sales service

3. Fast delivery time

4. We have CE, ISO9001 and GS certification.

- Q:Slings and rigging manufacturers, which cost-effective?

- Wire rope rigging, manganese phosphating coating steel wire rope is a new technology appearing in recent years. Wire rope has a long service life. Buy wire rope made of phosphating coating steel wire,

- Q:Where should I pay attention to the formwork?

- When the welded steel bar and the formwork are installed together, the following requirements shall be met:The formwork must be fixed on the joint of the load-bearing welded steel frame;When installing the reinforcing steel formwork assembly, the sling shall be tied up according to the hanging point designed by the template.

- Q:What are the dangerous sections of the crane hook?

- The sling tension A-A section on the one hand, the hook has straightened trend; also by the effect of bending moment on the other hand. Because the moment in this section, the bending stress is maximum, this section is a dangerous section.

- Q:What are the connections and differences between hooks, slings, rings and heavy truck rings in cranes? What are the hoisting designs?

- Synthetic fiber tape series: flexible sling, sling, ring ring cylinder cylinder eye sling, sling, flat glass, polypropylene flat sling, sling, sling fastening belt, pickling container windproof belt, hand woven tape, tied with tape, nylon, special oil pipeline pipe sling, sling dupont. (flat suspenders can produce 1T-30T, flexible suspenders, which can produce 1T-300T)

- Q:Which sling manufacturer is more reliable?

- Rigging is made of wire rope, plug or aluminium alloy head, and the key to the service life of the rigging is the quality of the wire rope.

- Q:What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 2. galvanized steel wire rope, including hot-dip galvanizing and electro galvanized two kinds, hot galvanized zinc layer is thick, long use time, galvanized thin, zinc layer thicker, corrosion protection ability is stronger. Because of the corrosion resistance of phosphating coating, the manganese phosphating coating steel wire rope can be used instead of some kinds of zinc coated steel wire rope, such as the B zinc coating in GB8918-2006.

- Q:What tools are slings in lifting operations? What is the function of the slings?

- Sling is one of the most common operation tools in hoisting operation.

- Q:Ceiling installation does not allow the use of air nails?

- Installation notes: installation should pay attention to the following three points.When installing, if there are many chandeliers, we should pay attention to their location, length and length, and install the ceiling lamp while installing the ceiling, so that the position and height of the lamp can be adjusted on the basis of the ceiling and joist.The hanger on the ceiling must be made by direct out method and by adding bushing. The method of adding sleeves is good for installation, and it can ensure the integrity of the ceiling panel. The boom that is directly out of the ceiling can not be easily drilled when installing, and sometimes the method of installing the suspender first and cutting the hole of the panel is adopted, but the decorative effect is affected.The boom should have a certain length of thread for adjusting height. Attention should be paid to the reliability of the hanging light box under the suspender and suspender.

- Q:How much is the crane arm of the tower from the residential building recently?

- No aluminum conductor or steel shall be used as grounding or ground wire for the installation of tower cranes. A bolted wire must have an end. Grounding is mainly made up of the following three ways:1. the grounding body adopts a regular grounding pile, or a 33*4.5 long 1.5m steel tube, or a 70*70 long 1.5m angle steel.2. the floor is made of steel plates or other metal plates with an area of 1 square meters. The ground is deep from the ground 1.5m.3. a copper conductor with a cross-section of not less than 28 mm or a steel conductor with a cross section of not less than 50 mm is buried in the slot and its embedment length is determined by the grounding resistance.In the above three ways, the grounding body leads the copper conductor, the sectional area shall be no less than 25, if the soil is not conductive, the sodium chloride (salt) can be embedded in the soil. Then irrigation. For walking crane, each rail must be grounded, and the two tracks are connected by wires. Electrical connections should also be made between the two rails, with a resistance of no more than 4.

- Q:Does the pressing rope have any influence on the tension value of the wire rope?

- The use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, manganese phosphating coating can greatly improve the wear resistance and corrosion resistance of the steel wire surface, the fatigue life of the phosphating coating steel wire rope is 3-4 times of smooth wire rope, up to 5 times, with the research on the wear resistance of the phosphating liquid, as well as to further improve the possibility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

0.25T Manual Chain Block HS-Z high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 200 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords