Chrome Steel Ball (G10) /52100 Balls/Bearing Ball/Steel Shot/Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

ASTM

Technique:

Hot Rolled,Cold Rolled

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

g10

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

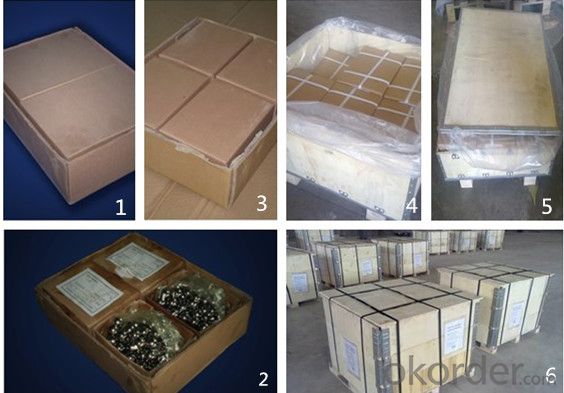

Packaging:

Standard Export Packing

Our company is a professional AISI 52100 15.875mm-150mm G10-GG1000 chrome steel ball manufacturer for more than two decades. Before reformation, it is the joint venture with LYC.

Production procession

According to the ISO9001, we have established the strict & perfect quality assurance system, making sure that the whole production process is controlled and steady quality is offered to satisfy customers.

Composition of Different Materials

| Material | Chemical of Different Materals | ||||||||

| C | SI | Mn | P | S | Ni | Gr | Mo | Cu | |

| AISI440C | 0.95-1.20 | 1.00max | 1.00max | 0.040max | 0.030max | 0.60max | 16.00-18.00 | 0.75max | _ |

| AISI420C | 0.42-0.50 | 1.00max | 1.00max | 0.040ax | 0.030max | 1.00max | 12.5-14.5 | _ | 0.30max |

| AISI304 | 0.08max | 1.00max | 2.00max | 0.045max | 0.030max | 8.00-10.5 | 18.00-20.00 | _ | _ |

| AISI316 | 0.08max | 1.00max | 2.00max | 0.045max | 0.030max | 10.00-14.00 | 16.00-18.00 | 2.00-3.00 | _ |

| AISI E52100&GC r15 | 0.95-1.10 | 0.95-1.10 | 0.50max | 0.025max | 0.025max | _ | 1.30-1.60 | _ | _ |

Applications:

Chrome steel balls are applied in bearings such as slew bearing, deep groove ball bearing, thrust ball bearing, self aligning ball bearing, double-row bearing and etc.

Packing:

Carton box by wonden plates

our products are very well known in more than European and other foreign countries. your cooperation and order are warmly welcome!

- Q:How is steel used in the production of industrial boilers and pressure vessels?

- Steel is commonly used in the production of industrial boilers and pressure vessels due to its high strength and durability. It provides the structural integrity required to withstand high pressures and temperatures. Steel is used for constructing the shell, tubing, and other components of these systems, ensuring safety and efficiency in various industrial processes.

- Q:How does the quality of steel affect its performance?

- The quality of steel directly impacts its performance. Higher-quality steel possesses superior strength, durability, and resistance to wear and tear. It also exhibits better heat conductivity and corrosion resistance, making it more suitable for various applications. Conversely, lower-quality steel may be more prone to breakage, deformation, and rapid deterioration, resulting in compromised performance and potentially unsafe conditions.

- Q:How is steel rebar welded for reinforcement in concrete structures?

- Steel rebar is commonly welded for reinforcement in concrete structures using a technique called "lap splicing." This involves overlapping two rebar bars and then welding them together using electric arc welding or resistance welding methods. The welding process ensures a strong bond between the bars, providing enhanced strength and stability to the concrete structure.

- Q:How is steel mesh used in construction?

- Steel mesh is commonly used in construction as a reinforcement material. It is mainly used to strengthen concrete structures such as floors, walls, and foundations. The mesh is placed within the concrete to provide additional tensile strength, preventing cracks and enhancing the overall durability of the structure. Additionally, steel mesh is used in the construction of fences, barriers, and cages to provide security and containment.

- Q:How is steel used in the production of laboratory equipment?

- Steel is used in the production of laboratory equipment due to its exceptional strength, durability, and resistance to corrosion, making it ideal for manufacturing various tools and instruments used in scientific research and experimentation.

- Q:What are the common types of steel products used in the pet grooming and care industry?

- Some common types of steel products used in the pet grooming and care industry include grooming scissors, blades, combs, brushes, nail clippers, and grooming tables. These products are often made from stainless steel, which is durable, rust-resistant, and easy to clean, making it ideal for the grooming and care of pets.

- Q:How are steel beams used in building structures?

- Steel beams are used in building structures to provide structural support and stability. They are commonly used as load-bearing elements to transfer the weight of the building to its foundations. Steel beams can span long distances and can support heavy loads, making them ideal for constructing large and tall structures like skyscrapers and bridges. Additionally, steel beams can be easily fabricated and installed, allowing for efficient construction processes.

- Q:What are the different types of steel angles and their applications in the manufacturing of machinery?

- There are several types of steel angles commonly used in the manufacturing of machinery. Some of the most common types include equal angles, unequal angles, and L-shaped angles. Equal angles have equal sides and are typically used for structural applications, such as providing support or reinforcement in machinery frames, brackets, or beams. They offer stability and strength, making them suitable for heavy-duty machinery. Unequal angles have different side lengths and are often used when specific strength or load-bearing requirements need to be met. They are commonly utilized in machinery components like supports, braces, or brackets, where different lengths are needed to distribute loads or provide stability. L-shaped angles, also known as corner or edge angles, are used for joining or connecting different parts of machinery. They are commonly employed in the construction of machinery frames, cabinets, or enclosures, providing structural integrity and stability. Overall, steel angles play a crucial role in the manufacturing of machinery by providing structural support, reinforcement, and connection points. The specific type of angle used depends on the intended application and the specific requirements of the machinery being manufactured.

- Q:How is steel used in the construction of railway bridges and tracks?

- Steel is used extensively in the construction of railway bridges and tracks due to its exceptional strength and durability. It is commonly used to fabricate structural components such as girders, beams, and columns, which provide support and stability to the bridge or track. Steel is also used for the production of rails, ensuring a smooth, reliable surface for trains to travel on. Additionally, steel's resistance to corrosion makes it ideal for withstanding the harsh outdoor conditions experienced by railway infrastructure.

- Q:What are the applications of alloy steel in manufacturing?

- Alloy steel is widely used in manufacturing due to its exceptional properties and versatility. It is utilized in various applications such as the production of machinery, automotive parts, tools, construction materials, and even in the aerospace industry. The high strength, durability, and resistance to corrosion and wear make alloy steel ideal for manufacturing components that require high tensile strength, toughness, and the ability to withstand harsh environments. Additionally, alloy steel can be easily machined, welded, and heat-treated, allowing for greater flexibility in the manufacturing process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Chrome Steel Ball (G10) /52100 Balls/Bearing Ball/Steel Shot/Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords