CHECK VALVE LIFT RUBBER FLAPPER DIN DUCTILE IRON DN40- DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure |

Power: | Manual | Material: | Casting | Temperature of Media: | Medium Temperature |

Port Size: | DN40-DN300 | Place of Origin: | China (Mainland) | Brand Name: | CMAX |

Application: | General | Medium: | Water, air, oil |

Packaging & Delivery

Packaging Details: | standard export packing plywood case |

Delivery Detail: | 30 days |

Features

● Rubber encapsulated disc

● Drain plug hole makes insertment of lifting equipment for flap possible

● Suitable for both horizontal and vertical installation

● FBE coated inside and outside

● Product color:Blue RAL5017

Technical Specification

● Flanges Drilling:EN1092-2 PN16

● Hydraulic test to ISO5208

Seat Test Pressure:17.6 bar

Shell Test Pressure:24 bar

● Maximum temperature:70℃

Materials

| Parts Name | Material |

| Valve body | Dutile iron, stainless steel, Cast Seel |

| Valve gland | Dutile iron, stainless steel, Cast Seel |

| Connection type | Flange connection |

| Application temperature | ≤80°C |

| Valve disc | Stainless steel+ nylon cloth wrap |

- Q:What are the brands of check valves?

- Also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium.

- Q:God, can you explain to me in detail why?

- Check valve in the valve in front. To prevent water from flowing back.

- Q:What's the W in the check valve H44W?

- W represents the sealing surface is the body seal, that is, directly from the valve body out of the sealing surface

- Q:The difference between the plunger type check valve and the lift check valve

- Lift check valve is to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium. The check valve can also be used to provide a supply to the auxiliary system where the pressure may rise above the system pressure. The check valve can be mainly divided into swing check valve (rotating by gravity center) and lift check valve (moving along the axis).Hope to be of some help to you!

- Q:Installation of stainless steel tank outlet must be equipped with check valve?

- A stainless steel ball valve can also ah, inner thread

- Q:What are the differences between the vertical check valve and the horizontal check valve in function and principle?.

- The check valve has a baffle inside it, usually closed by gravity,The function and working principle are basically indistinguishable

- Q:What is the reason that the valve is not used for a period of time?Anonymous browsing | 314 times

- 4 the vertical lift check valve shall be mounted on a vertical pipe.5, the lift type horizontal check valve shall be installed on the horizontal pipe.6. Do not check the weight of the valve in the line. The large check valve shall be independently supported so as not to be affected by the pressure caused by the piping system.

- Q:Can the slow stop disc check valve close quickly?

- At this point, the valve will automatically close under the influence of the spring and the medium return. However, as the piston rod is in an extended position, the valve can not be closed all the way, and there is about 20% of the area left to make the medium pass, so as to eliminate the water hammer. The disc is divided into two parts by the piston, which is fast, slow and slow. It can not only prevent the motor from reversing, but also eliminate the mute effect.

- Q:What's the difference between the cut-off, check, check, and stop valves three? Better picture,

- Stop check valve: when the handwheel is rotated so that the valve stem rises, the disc does not rise together, but only the valve clack is released.

- Q:What can I do with the lift check valve?

- With the structure of short length, small volume and light weight, the valve closed fast, water hammer pressure, flow smooth, fluid resistance small, horizontal or vertical pipe pipe can be used, easy installation, quick action, good sealing performance, the valve stroke is short, close the valve impact force is small, simple and compact, beautiful appearance, service life long, high reliability, to prevent the media back, the characteristics of automatic control. A lift check valve is used on an industrial pipe to prevent the flow of a medium.

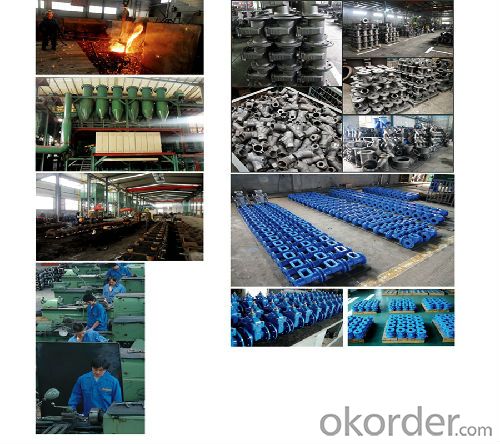

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CHECK VALVE LIFT RUBBER FLAPPER DIN DUCTILE IRON DN40- DN300

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords