Ceramic Fiber Bulk /Loose Ceramic Fiber ( 1000C-1260C-1350C-1400C-1500C-1600C )

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 20000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Bulk /Loose Ceramic Fiber ( 1000C-1260C-1350C-1400C-1500C-1600C )

Ceramic fiber friction material is made from standard ceramic fiber blown bulk through shear, slag removal processes, and secondary processing, as one of ideal raw material for production of friction materials . As the crucial and staple materials for producing ceramic fiber blanket, board, module and other formed products, Hitex ceramic bulk fiber is normally manufactured from high purity raw materials-alumina powder, silica sand through unique production techniques of spun or blowing, these bulks are loose, long and flexible with fine thermal properties, at present, the chopped fibers for vacuum formed production, the lubricated bulk fibers and the fiber for textiles are all available. Hitex ceramic bulk fibers serve as an ideal filler for various types of refractory lining and insualtion tools.

Main Product Features:

1.Low heat storage and thermal conductivity.

2.Excellent chemical and thermal stability.

3.Contains no bonding agent ad corrosive substance.

4.Thermal shock resistance and acoustic absorption.

5.Asbestos free and flexible applications.

Product Applications:

Ceramic Fiber Bulk are ideal for use in the below applications

1. Staple materials for other ceramic fiber products.

2. Expansion media.

3. Mouldable feedstock

4. Ladle insulation

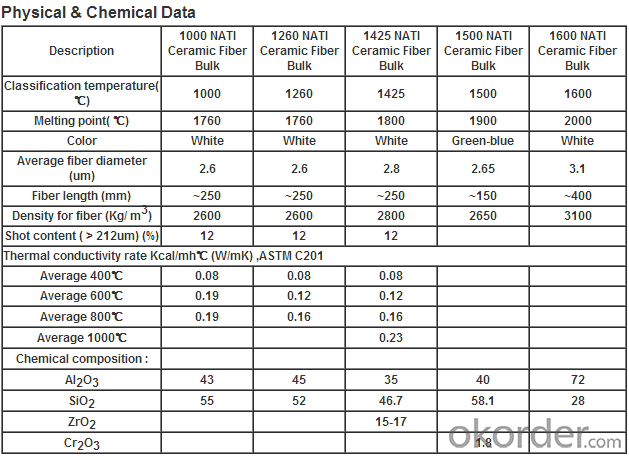

Product Specifications:

FAQ:

1. When can I get the price?

We will try our best to provide you the price within 24 hours after received your inquiry.

2.Can I get samples?

Yes, of course. Free samples will be provide for your testing. The samples will be sent out within 3 days after your confiremation of density, size, qty etc.

3.What about the payment terms?

As for the payments, every payment terms can be negotiable.

Product Picture

Produce Processing

- Q:What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Service life: ordinary furnace quenching, sudden heat, easy to cause blasting chamber or cracking, shorten service life, ceramic fiber furnace without blasting chamber or crack possible.There are two common practices in ceramic fiber furnaces:The first is a larger furnace, which is fixed on the furnace wall with ceramic fiber modules;The second is a small furnace, the manufacture of abrasives, direct pouring, or with punch milling machine processing ceramic fiber board.

- Q:What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density is only a standard in the world, is 220Kg/m fand, but in the actual application, according to the heat treatment furnace, furnace temperature, combustion medium, temperature rise requirement of ceramic fiber module density in 200-240Kg/m fand, ceramic fiber blanket, because the processing of ceramic fiber module uses double roller today advanced technology and technology of silk, fiber length of the ceramic fiber blanket which produced in 80-130 mm, so the maximum density of the ceramic fiber module is more than the density, 240Kg/m fand, a large amount of fiber fracture, the fracture rate is as high as 48%. So after the actual verification at home and abroad of tens of thousands of industrial furnaces, the best density of ceramic fiber module is fand 220Kg/m.

- Q:What is the diameter of the ceramic fiber? How to mix?

- The diameter of the general ceramic mineral fiber is 2---5 microns, and the length is in the range of 0---8 mm long.Ordinary mixing machine can be easily mixed, and the mixture of other good affinity, evenly dispersed and mixed resin or rubber and liquid glue, thus make the fiber products look pretty smooth, bright color, anti impact friction resistance, small abrasion, tensile Xinghao, can effectively reduce the noise without damage dual, can reduce the amount of metal fiber.

- Q:Should the ceramic fiber furnace be compacted?

- The simplest, the least durable method, uses ceramic fiber blankets for wrapping, which is often caused by the poor density of the ceramic fiber blanket and the lack of anchorage

- Q:Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- Because pneumoconiosis can not be cured by medical treatment, it brings great pains to the patients and the families. It is suggested that respiratory protection work be carried out.

- Q:Ceramic fiber material fire shutter door how many square?

- Now there are two kinds of rolling to use ceramic fiber: a called inorganic super fire shutter (commonly known as the double track curtain), the curtain surface is glass fiber cloth + ceramic fiber cloth + ceramic fiber blanket + aluminum foil cloth, one is WFJ (glass fiber cloth + ceramic fiber cloth + glass fiber cloth).

- Q:Is the ceramic fiber cloth poisonous?

- Ceramic fiber clothProduct introduction.Ceramic fiber products with excellent heat resistance, with heat-resistant alloy reinforced aluminum silicate dimensional textiles, continuous use temperature of 1000 degrees, excellent acid resistance and oil, water vapor corrosion capacity.

- Q:Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminosilicate ceramic fiber has two different production processes, respectively, the rejection process and the blowing process. The carpet produced by the spinning process has long fiber length, high tensile strength and wide range of use. The blanket produced by blowing process is short in length and easy to break, and the scope of application is relatively narrow.

- Q:What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Applicability: glass fiber (melting point 680 degrees) belongs to medium and low temperature insulation material, suitable temperature is below 700 degrees, aluminum silicate fiber belongs to high temperature insulation material, use fire temperature 1000~1790 degrees.

- Q:What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- High temperature is similar to that of strength, service life, the price is high silica cloth. High silica fabric belongs to glass fiber.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Bulk /Loose Ceramic Fiber ( 1000C-1260C-1350C-1400C-1500C-1600C )

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 20000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches