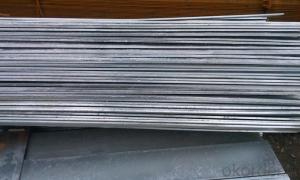

Carbon Steel Flat with Q195-Q235 for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Carbon Steel Flat with Q195-Q235 for Construction:

Commodity: Hot Rolled Steel Flat Bar

Standard: GB;JIS

Material: Q195-Q235

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Usage/Applications of Carbon Steel Flat with Q195-Q235 for Construction:

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

Production Flow of Carbon Steel Flat with Q195-Q235 for Construction:

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

Packaging & Delivery of Carbon Steel Flat with Q195-Q235 for Construction:

1.Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

2.Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer requests.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q:What about the installation height of the socket and the height of the ground flat steel?

- If the construction unit, design institute and contact Party A drawings or design change

- Q:What are the different methods of surface embossing for steel flat bars?

- Steel flat bars can be embossed using various methods. One commonly used technique is roller embossing, where the flat bar is passed between two rollers with a patterned surface. As the bar goes through the rollers, the pattern is imprinted onto its surface, resulting in an embossed design. Another method is press embossing, where the flat bar is positioned between a patterned die and a matching counter die. By applying pressure to the dies, the pattern is pressed into the bar's surface. Laser embossing is a third option, which entails utilizing a laser beam to selectively remove material from the bar's surface in a patterned way. This method allows for the creation of diverse embossed patterns, as the laser can be controlled accordingly. Furthermore, chemical embossing is also available. This involves applying a chemical solution to the bar's surface, which reacts with the metal and forms an embossed pattern. Each method possesses its own set of advantages and disadvantages. The choice of method depends on factors such as the desired pattern, design complexity, and project constraints such as cost and time limitations.

- Q:What is the difference between hot-rolled and cold-rolled steel flat bars?

- The main difference between hot-rolled and cold-rolled steel flat bars lies in their production process and resulting characteristics. Hot-rolled steel flat bars are made by heating a steel billet or slab to a high temperature and then rolling it through a series of rollers to achieve the desired shape and size. This process results in a relatively rough surface and rounded edges. On the other hand, cold-rolled steel flat bars are produced by cooling down the hot-rolled steel to room temperature and then passing it through a series of rollers at room temperature. This process results in a smoother surface finish and sharper edges compared to hot-rolled steel flat bars. In terms of physical properties, hot-rolled steel flat bars generally have a larger size tolerance, as the high-temperature rolling process can cause some dimensional variations. Cold-rolled steel flat bars, on the other hand, have a tighter size tolerance due to the controlled cold-rolling process. Additionally, due to the heating and cooling process involved in their production, hot-rolled steel flat bars typically have a scaled surface, which is a thin layer of iron oxide. In contrast, cold-rolled steel flat bars have a clean, smooth surface. Moreover, the mechanical properties of hot-rolled and cold-rolled steel flat bars also differ. Hot-rolled steel flat bars tend to have a lower yield strength and higher ductility, making them suitable for applications that require shaping or bending. Cold-rolled steel flat bars, on the other hand, have a higher yield strength and lower ductility, making them more suitable for applications that require strength and durability. In summary, the key differences between hot-rolled and cold-rolled steel flat bars lie in their production process, surface finish, dimensional tolerance, and mechanical properties. The choice between the two depends on the specific requirements of the application and the desired characteristics of the steel flat bars.

- Q:Can steel flat bars be used for creating frames or supports in artwork?

- Yes, steel flat bars can be used for creating frames or supports in artwork. Steel is a strong and durable material that can provide stability and structural integrity to art frames and supports. Its versatility allows for various artistic designs and it can be easily manipulated and welded to create custom shapes and sizes. Additionally, steel's aesthetic appeal can complement and enhance the overall presentation of the artwork.

- Q:Can steel flat bars be used for architectural applications?

- Yes, steel flat bars can be used for architectural applications. Steel flat bars are versatile and durable, making them suitable for various architectural projects. They can be used for structural support, such as in beams and columns, as well as for decorative purposes, like in handrails or trim details. Steel flat bars can be easily fabricated and shaped to meet specific design requirements, allowing architects to create unique and visually appealing structures. Additionally, steel flat bars are available in a wide range of sizes and finishes, offering architects flexibility in selecting the most suitable material for their architectural projects.

- Q:How do steel flat bars contribute to the overall sustainability of structures?

- There are several ways in which steel flat bars contribute to the overall sustainability of structures. Firstly, the use of steel flat bars ensures that structures have a longer lifespan compared to those made with other materials, as steel is highly durable and long-lasting. This reduces the need for frequent repairs or replacements, resulting in less waste and a lower overall environmental impact. Secondly, steel is a highly recyclable material, and flat bars can be easily melted down and reshaped into new products without losing their inherent properties. This reduces the demand for new steel production and the extraction of raw materials, leading to a significant decrease in energy consumption and greenhouse gas emissions. Furthermore, steel flat bars have a high strength-to-weight ratio, meaning that less material is needed to achieve the same structural integrity compared to other materials. This results in lighter structures, which require less energy for transportation and installation. Additionally, the reduced weight allows for more efficient designs, enabling the use of smaller foundations and fewer materials overall. Moreover, steel flat bars offer versatility in design and construction. They can be easily fabricated into various shapes and sizes, allowing architects and engineers to create innovative and efficient structures. The flexibility of steel flat bars also allows for greater adaptability and reusability, as structures can be modified or repurposed instead of being demolished and rebuilt. Lastly, steel is highly resistant to natural disasters such as earthquakes, hurricanes, and fires. Structures built with steel flat bars can withstand these events better, reducing the potential for severe damage and the need for complete reconstruction. In conclusion, the incorporation of steel flat bars into construction projects contributes to the overall sustainability of structures by providing durability, recyclability, lightweight design, versatility, and resilience to natural disasters. This not only minimizes waste and reduces energy consumption, but also lowers greenhouse gas emissions and creates long-lasting, environmentally friendly structures.

- Q:What are the different bending techniques for steel flat bars?

- Steel flat bars can be bent using various techniques depending on the desired shape and project requirements. The most commonly used bending techniques for steel flat bars are as follows: 1. Cold Bending: This technique involves gradually bending the bar at room temperature using manual or mechanical presses, or bending machines. It is the most widely used method. 2. Hot Bending: Another technique is hot bending, which involves heating the bar to a high temperature to increase its malleability before shaping it. Furnaces or torches are typically used for heating. 3. Roll Bending: This technique requires passing the steel flat bar through a series of rollers to achieve the desired shape. It is commonly used for large-scale projects and can be done manually or with specialized machinery. 4. Mandrel Bending: In this technique, a solid rod or tube called a mandrel is inserted into the steel flat bar to provide support and prevent deformation during bending. It is often used for small radius bends or complex shapes. 5. Press Brake Bending: Press brake machines are employed in this technique to apply pressure and bend the steel flat bar. A punch and die are used to form the desired bend. It is important to consider factors such as the size, thickness, and bend radius of the steel flat bar, as well as the specific project requirements when choosing a bending technique. Consulting with a professional or metal fabrication expert is recommended to determine the most suitable technique for a particular application.

- Q:What are the standard lengths available for steel flat bars?

- The available lengths for steel flat bars differ based on the manufacturer and customer specifications. Typically, these bars come in lengths ranging from 6 to over 20 feet, with variations based on industry standards or customer preferences. Notably, custom lengths can be obtained by cutting or shearing the steel flat bar to the desired size.

- Q:What are the common industries that use steel flat bars?

- The common industries that use steel flat bars include construction, manufacturing, automotive, aerospace, and mining.

- Q:What is the use of slitting flat steel?

- Compared with the conventional steel plate, slitting flat steel has the following advantages:1, the product surface is bright and clean. Two times in the process of high-pressure water descaling process, to ensure that the steel surface clean and bright.2, special product specifications. The thickness of 8~45mm, width 150-600mm, length 5-15m, and the product specifications span is dense, can meet the needs of users, instead of in use, without cutting board, we can directly carry out welding.3, both sides of the vertical, clear water chestnut. The two vertical rolling in the finishing mill ensures good verticality of both sides, clear corners and good quality of the edges.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Flat with Q195-Q235 for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords