Carbon Mild Steel Universal Beam in I Shaped Form Chinese Standard Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Carbon Mild Steel Universal Beam in I Shaped Form Description:

Carbon mild steel universal beam in I shaped form is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Carbon mild steel universal beam in I shaped form is usually made of structural steel and is used in construction and civil engineering. The carbon mild steel universal beam in I shaped form resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Carbon mild steel universal beam in I shaped form theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Carbon Mild Steel Universal Beam in I Shaped Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Carbon Mild Steel Universal Beam in I Shaped Form Images:

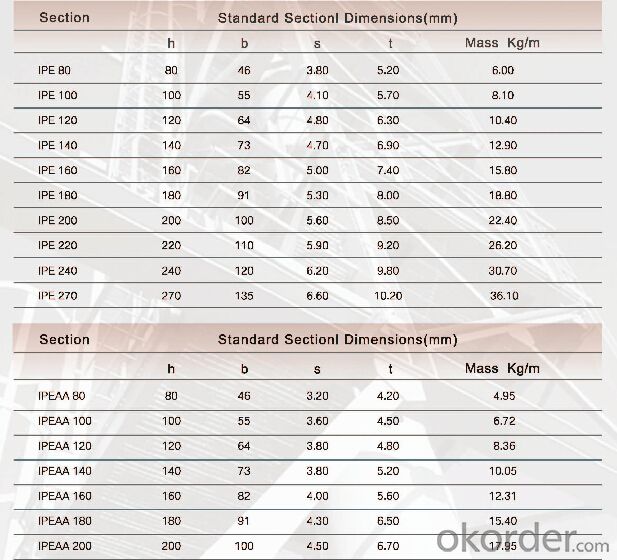

4. Carbon Mild Steel Universal Beam in I Shaped Form Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:How are steel I-beams connected in construction?

- Steel I-beams in construction are connected using various methods, depending on project requirements. The most common connection methods are welding, bolting, and riveting. Welding, a widely employed method, involves melting and fusing the ends of the beams using intense heat. This creates a strong and permanent bond, ensuring structural integrity. Welding is preferred when a particularly strong and rigid connection is needed. Bolting, another common method, is used when flexibility and easy disassembly are desired. Beams are secured together with bolts through pre-drilled holes in the flanges or webs. This method allows for adjustments and modifications during construction and is suitable for situations where future alterations may be required. Riveting, although less prevalent in modern construction, still finds use in certain cases. It entails driving a steel rivet through aligned holes in the beams and hammering or pressing it to create a permanent connection. Riveting was historically extensively used in older structures. While durable and visually appealing, it is time-consuming and requires skilled labor. In addition to these methods, adhesive bonding and mechanical connectors may be used in specific situations. Adhesive bonding involves using industrial adhesives to join the beams, while mechanical connectors employ specialized connectors like shear plates or end plates. Ultimately, the choice of connection method relies on factors such as load requirements, structural design, construction timeline, and budget. Engineers and construction professionals carefully assess these factors to determine the most appropriate method of connecting steel I-beams for each project.

- Q:How are steel I-beams used in multi-story buildings?

- Steel I-beams are used in multi-story buildings as structural components that provide support and stability. These beams are typically made of steel due to its strength and durability. I-beams are designed to carry heavy loads and distribute the weight evenly across the structure. They are often used as horizontal beams, known as floor joists, to support the weight of the floors and any additional loads such as furniture, equipment, and people. In addition to supporting the floors, steel I-beams are also used as vertical columns or beams to provide vertical support for the entire building. These columns help to transfer the weight of the upper floors down to the foundation, ensuring the stability and integrity of the structure. The use of steel I-beams in multi-story buildings is advantageous due to their high strength-to-weight ratio, meaning they can support heavy loads without being overly bulky or cumbersome. This allows for more efficient use of space and allows architects and engineers to design taller and more spacious buildings. Furthermore, steel I-beams are fire-resistant, which is crucial for the safety of occupants in case of a fire. They can withstand high temperatures for a longer period compared to other building materials, minimizing the risk of structural collapse. Overall, steel I-beams play a critical role in multi-story buildings by providing structural support, distributing loads, ensuring stability, and enhancing the safety and longevity of the structure.

- Q:What is the maximum allowable deflection of No. 16 I-beam suspension 1300?

- Your question is somewhat questionable: the maximum allowable deflection limit value is determined by the use of requirements, such as bridges, buildings, lifting equipment have corresponding specification requirements. As for the size of deflection, and stress related position such as load, concentrated force, force and force, you can not be self deflection (related to steel I-beam direction), top concentrated force, the maximum deflection is y=P * l^3 / (3 x E * I), when both load, y=q * l^4 / (3 * E * I).

- Q:How do steel I-beams perform in terms of fatigue resistance?

- Steel I-beams are known for their excellent fatigue resistance. Due to their shape and design, I-beams can withstand repeated loading and unloading without experiencing significant fatigue failure. The structural integrity and high strength of steel make I-beams highly resistant to fatigue, making them a preferred choice in many construction and engineering applications.

- Q:What are the different types of steel surface treatments available for I-beams?

- There are several types of steel surface treatments available for I-beams, each offering unique benefits and applications. 1. Hot-dip galvanizing: This is a widely used method where the I-beam is dipped into a bath of molten zinc. The zinc coating provides excellent corrosion resistance, making it suitable for outdoor applications. It also provides a barrier against moisture and physical damage. 2. Powder coating: It involves applying a dry powder to the I-beam's surface, which is then heated and cured to create a durable and decorative finish. Powder coating offers a wide range of colors and textures, making it popular for architectural and aesthetic purposes. 3. Epoxy coating: This is a two-part coating system that consists of a resin and a hardener. It provides excellent chemical resistance and protection against corrosion. Epoxy coatings are commonly used in industrial settings where the I-beams may come into contact with chemicals or harsh environments. 4. Paint coating: This is a traditional method where paint is applied to the surface of the I-beam. It provides some level of protection against corrosion but is generally less durable compared to other surface treatments. Paint coatings are often used for indoor applications or when aesthetics are a priority. 5. Shot blasting: This is a mechanical surface treatment where small steel shots are propelled at high speeds to remove rust, scale, and other contaminants from the I-beam's surface. Shot blasting creates a clean and rough surface, allowing for better adhesion of subsequent coatings or paints. It is important to consider the specific requirements and environmental conditions when choosing a steel surface treatment for I-beams. Consulting with a professional or a steel manufacturer can help determine the most suitable treatment for a particular application.

- Q:Are steel I-beams subject to any specific building code requirements?

- Steel I-beams must adhere to specific building code requirements, which are regulations and standards that dictate the minimum criteria for building design, construction, and materials. These codes aim to guarantee the safety and structural stability of buildings. Regarding steel I-beams, building codes typically encompass requirements related to their size, shape, and material properties. These specifications are based on factors like the loads the beams will bear, their span, and the overall structural design of the building. For example, building codes may stipulate the minimum dimensions and shape of I-beams, along with the recommended steel type, such as ASTM A992 or ASTM A36. Codes may also dictate the spacing and connections between beams, as well as any necessary additional reinforcement or bracing. Furthermore, building codes often mandate that qualified professionals install steel I-beams and that building officials inspect them to ensure compliance with the code requirements. This ensures proper installation and the ability of the beams to support intended loads. Overall, the specific building code requirements for steel I-beams vary depending on the jurisdiction and the type of building under construction. Architects, engineers, and construction professionals must familiarize themselves with the relevant building codes and ensure that all steel I-beams meet the necessary standards for safety and structural integrity.

- Q:Can steel I-beams be used for food processing plants?

- Yes, steel I-beams can be used for food processing plants. Steel I-beams provide structural support and are commonly used in industrial settings, including food processing plants, where they offer strength, durability, and stability for various equipment and infrastructure.

- Q:Can steel I-beams be used in foundation or basement construction?

- Indeed, foundation or basement construction can incorporate steel I-beams. The utilization of steel I-beams is widespread in the construction industry, owing to their robustness and longevity. Particularly in regions where soil conditions are unstable or when substantial loads necessitate support, they can offer exceptional reinforcement for foundation or basement walls. Furthermore, steel I-beams possess resistance against rot, pests, and moisture, rendering them an optimal selection for basement construction. Nevertheless, it is vital to seek guidance from a structural engineer or construction expert to ascertain the suitable dimensions and positioning of the steel I-beams, taking into account the specific demands and circumstances of the building.

- Q:Can steel I-beams be used for long-span structures?

- Yes, steel I-beams can be used for long-span structures. Steel I-beams are known for their strength and ability to bear heavy loads, making them suitable for long-span structures such as bridges, industrial buildings, and large commercial spaces. The use of steel I-beams allows for the creation of open and spacious areas without the need for intermediate supports. Additionally, steel I-beams can be easily connected and fabricated to create longer spans, providing flexibility in design and construction. The high strength-to-weight ratio of steel also makes it a preferred choice for long-span structures as it allows for lighter structures without compromising on strength and stability. Overall, steel I-beams are widely used in the construction industry for long-span structures due to their durability, strength, and versatility.

- Q:What is the most cost-effective size for a steel I-beam?

- The most cost-effective size for a steel I-beam depends on various factors such as the load it needs to support, the span or distance it needs to cover, and the specific requirements of the project. A structural engineer or a steel fabricator would be best suited to determine the most cost-effective size based on these specific project parameters.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Mild Steel Universal Beam in I Shaped Form Chinese Standard Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords