Cantilever Formwork with Great Performnce for Multi-storey Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Cantilever Formwork Description

Cantilever Formwork is mainly used in the concrete pouring of pier, high buildings, and so on. The concrete lateral pressure is entirely supported by anchor system and the wall-through tie-rods, additional reinforcement is not needed. The construction is easy, rapid and economical. A single pouring height is high and the finished concrete surface is perfect. Cantilever formwork has several types, the structure is similar, and has its own different characteristic. Can use them according to actual demand.

Main cantilever Formwork:PJ200 & PJ240,CB-240 etc.

Cantilever formwork is used in dams, piers, retaining wall and cooling tower etc. All the concrete side-pressure is borne by the anchors and the brackets. As there is no through-wall tie-rod, the concrete is very clean.

The formwork can be moved backward by 600mm for cleaning the formwork and fixing the reinforcing steel bar. Waler connector is used for connecting the form to ensure form alignment.

Form can be pushed to the already cast concrete by turning the adjust carriage to avoid concrete offset or leakage.The formwork can be moved freely as you request. The formwork can be inclined backward and forward. Max. angle: 30°. High standard elements can be widely used.

2. Main Features of Cantilever Formwork

-easy to assemble

-simple structure.

-easy, rapid and economical.

The M30/D20 climbing cones have been designed especially for single-sided concreting using cantilever formwork in dam construction, and to allow the transfer of high tensile and shear forces into the still fresh, unreinforced concrete. Without wall-through tie-rods, finished concrete is perfect.

3. Cantilever Formwork Images

4. Cantilever Formwork Specifications

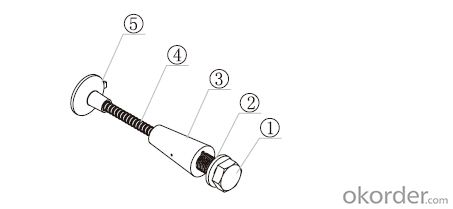

Anchor system

Anchor system is the most important supporting part. The system is made of five parts shown below. There into, tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusing after the concrete pouring.

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤Ancor plate D15

5.FAQ of Cantilever Formwork

1) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

2) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

- Q:The latest version of the external scaffolding erection norms and template engineering construction quality acceptance specification which two ah? Thank you

- The current template specification is JGJ162-2008 "construction formwork safety technical specifications"; belong to the high formwork project also must obey GB50666-2011 "concrete structure engineering construction code" fourth chapter

- Q:PLEASE HELP!!!

- maybe the fact that it marked the point where she began to see things from a different perspective than the colonists (figuratively and literally) Hawthorne later says that she began to think unnatural thoughts for a colonist..... Hope this helps, we didn't really discuss this while we read it ^_^

- Q:I've had my industrial piercing for almost 5 years now and I was wondering if I was to take it out if it would close up or how long it would take to close. And after I take it out will it be noticeable that it was there.

- If you had it for 5 years it won't close up since its healed up. The holes on mine are pretty small but I have hair covering mine so you can't see it but I've only had mine a little over a month. I do have other piercing that haven't ha anything in for a while and they are not closed like my belly button and I got that done about 7 years now.

- Q:what is differences between scaffold and scaffolding?

- Scaffold is what scaffolding is constructed of.

- Q:is both 1 m farm from the scaffold. if the boeard is 20 kg in mass, how close to the end can the painter stand w/out tipping the board over?

- 1.692m, but you should have included a diagram, I am still not sure if you are talking about a cantilever force couple or a simple lever pivot..

- Q:All I know about the guy is that in the end, he doesn't get the girl he wanted and his head gets chopped off. Please don't give me critiques or anything like that. I just want the story. Thanks.

- March To The Scaffold

- Q:Okay, so my mums allowed me to get either my belly button pierced or to get scaffolding (Which she doesn't like that much) pierced, I really want both done but I have no idea which one I want so I was hoping on some opinions to help me choose? :) thanks x

- belly button. it looks cute

- Q:The scaffold is 18 m long. A 650-N box sits 3.0 m from the left end. What is the tension in each wire? left wire = 520 N; right wire = 130 N left wire = 640 N; right wire = 210 N left wire = 195 N; right wire = 975 N left wire = 295 N; right wire = 1000 N can someone show me how to do this please :)

- Lets call left wire T1, right = T2 T1 = (200 x 9) + (650 x 15) = 11550 11550 = 18T1 11550/18 = 641.67 N T2 = (200 x 9) + (650 x 3) = 3750 3750 = 18T2 3750/18 = 208.33 N left wire = 640 N; right wire = 210 N

- Q:The kind of hot galvanized scaffolding, many site use is very beautiful now, I would like to ask the material and the characteristics of this shelf there is how to install?

- In use, only need to put the plug into the hole of the ends of the cross rod pole corresponding, and then knock tightly, the quality of the demolition ride fast and overlapping is the traditional scaffold cannot do. Its erection speed is 4-8 times more than 2 times that of steel pipe scaffold. Let me explain in the form of a picture

- Q:Bowl buckle scaffold can be used to support it

- This bowl buckle scaffold will be built more stable, reduce the probability of accidents

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cantilever Formwork with Great Performnce for Multi-storey Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords