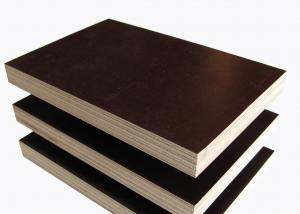

Brown Film Faced Plywood Shuttering Plywood

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specification:

Core: Poplar/birch/combi/hardwood core

Glue: WBP/Melamine/MR

Film Color: Dark brown, black film. Other colors, like yellow, green, grey, can be specially ordered.

Thickness : 4 6.5 9 12 15 18 21 24 27 30 mm

Description:

Product Name | Film Faced Plywood | |

Size | 1220*2440MM/1250*2500MM/1500*3000MM or As per customer requested | |

Length(width) tolerance | +/-1mm | Thickness 9-30mm |

Diagonal line | +/-2mm | Thickness tolerance +/-0.5mm |

Film | Black/Brown Film | |

Logo | Logo-Comaccord, Customized logo by customers. | |

Surface | Smooth/wiremeshed(anti-slip) | |

Core material | Materials:Poplar/birch/combi/hardwood(eucalyptus) | |

Glue | WBP(Weather/boil proof)/Melamine/MR | |

Density | 550-700kg/cbm | |

Cycle life | 6-20times | |

Moisture | 6-12% | |

Warpage |

| |

Edge | Sealed with water-proof paint, and different colors are available for us | |

Pallets | Pts/40'GP:16 pallets | Pts/40'HQ:18 pallets |

Veneer layers (longitudinal grain with transverse grain crossed, glue-sprayed among each layers) | 9mm:5 or 7 layers | 12mm:7 or 9 layers |

15mm:9 or 11 layers | 18mm:11 or 13 layers | |

21mm:13 or 15 layers | 25mm:15 or 18 layers | |

Hot press | Only two time hot preseed (Different: two times hot pressed plywood-smooth surface, one time hot pressed-low cost and cheap price), Comaccord only produce high quality product. | |

Capacity | 500-1000m3/day | |

Features:

1. Light Weight: We choose the high grade eucalyptus and poplar as the basic material, they are very light, so Chanta film faced plywood is convenient for transporting, and only one person could delivery single formwork by hand.

2. Easy To Cut: the plywood is easy to cut, so according to the construction, the formwork could be cut into the required size.

3. Re-used: Chanta film faced plywood could be used 8-10 times.

4.Multi Using: Chanta film faced plywood could be used for wall, slab, column, beam and bridge concrete pouring etc..

5. No Deformation: Chanta film faced plywood is also whole but not deformation and chipping after 72 hours cooking in boiling water.

6. High Quality Film: Chanta film faced plywood is filmed by Dynea brown or black film imported from Finland, it protect the formwork surface from the corrosion and makes the formwork durable, improves the flatness of the concrete surface and makes the concrete surface save

the second time plastering, so it could save a lot cost of construction.

FAQ:

1)Payment term:T/T deposit,balance against shipping documents,L/C.

2)Samples:free samples as request

3)Quality control:professional QC teams to make sure goods quality

- Q:How to use building plywood?

- Four types of plywood for the tide resistant plywood, used in the indoor normal, general purpose plywood with beech, linden wood, ash, birch, elm, poplar and so on.

- Q:What are the plywood specifications?

- International Organization for Standardization of ordinary plywood production, from the structure, finished product moisture content, quality 3 to make the provisions:

- Q:What are the processing defects of plywood?

- Warping warPing is generally a regular deformation, part or all of the surface of the plywood is curved.

- Q:What is the use of plywood for construction?

- The outermost front panel is called a panel, the back is called a backplane, and the inner board is called a core plate

- Q:Multilayer board, also known as three plywood and plywood

- usually with odd-level veneer, and the adjacent layer The fiber orientation of the veneer is perpendicular to each other

- Q:The Preparation of plywood ingredients

- Loose loose side In the process of peeling or slicing, the side of the board and the knife contact side, this side due to reverse expansion and often produce a bottle peeling or cut fissure.

- Q:Hard fiber board is also a density board

- , the same tree species or similar tree species, the same processing method (peeling or slicing)

- Q:What is the type of plywood editing?

- the plywood is divided into decorative plywood (for the surface needs to paint transparent paint Furniture, sewing machines and all kinds of electrical appliances and other products)

- Q:Solid wood and plywood which is better?

- Can not completely determine which is better, this depends on how you use the main.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Brown Film Faced Plywood Shuttering Plywood

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords