Ball Lead Screw SFU1605

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Sets set

- Supply Capability:

- 1000 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

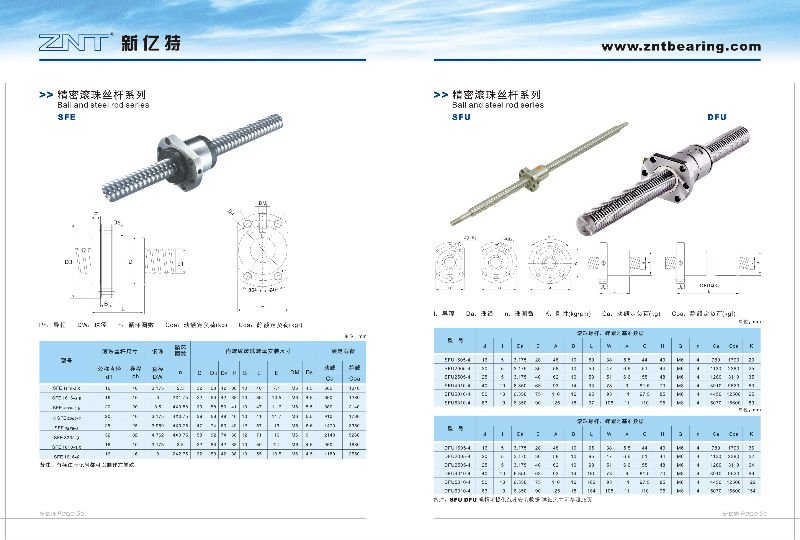

The ball lead screw we produced has the precision C5,C7 with high quality and best price. You will be benefit from it.

We are a factory which specilizes in producing various kinds of bearing, such as ball lead screw, linear guide rail, rod ends bearing, slider unites and etcs.

The quality of our products is in accordance with International standard or National standard entirely. We have attained IS09001:2000 International Quality Certification.

We welcome inquiries from domestic and overseas customers.

The picture about our products and factory:

- Q:Who knows who invented the screw?

- Greek mathematician Archimedes invented the thread, but until the 15th century only appeared the first screw, do not know who is its inventor. 1550 years with wood screws, until 1774 only invented a screwdriver. In 1936, Henry M. Philips applied for a patent for the screws of the crosshead head

- Q:What is the effect of the screw?

- Special purpose screws such as rings are used for lifting parts.

- Q:What is the meaning of the screw and the 4 and 8?

- He means that the tensile strength of the screw minimum 400MPa, the minimum yield strength of 320MPa (tensile strength of 80%). Please refer to the national standard GB3098.1 or ISO international standard ISO898-1 the requirements.

- Q:How did the scrHow did the screw become round?ew become round?

- (1) in the screwdriver head pad things such as double-sided adhesive, non-woven fabrics, etc. If there is no condition, then the paper can be, so you can increase the friction. (2) with a small amount of 502 glue into the screw hole, and then screw into the screw, and so the glue after the solid tip and then use the tip of the screw to pull out the screw (only the screwdriver is not afraid of causing screw teeth). (3) fruit screw cap exposed, you can use the tip of the clamp clamp screw cap after the screw. (4) the general mobile phone screws are metal, the case is plastic, not screw down when the time. You can use the tip of the screw into the screw cap, the metal screws to screw the plastic around the plastic melting, with the tip of the clamp clamp, gently pull out! You can also force down the screws about 1 mm (be careful not to engage in the chassis), you can solve the problem of loose screws. (5) so little the screw is not easy to get, my father had to repair the original bike screw method, with a small electric drill in the middle of the screw to play a not deep hole, and then find an anti-silk tap into the (must Anti-wire tap, it is difficult to find, to go to a large measuring blade cutting shop), you can unscrew the.

- Q:Screw M is mechanical teeth, tapping is what?

- There are many kinds of tapping teeth, such as: triangular teeth, iron teeth, wood thread, etc. Usually used TP said

- Q:This screw ye use, and how to use next to the cover

- This is also the expansion screw. First make a hole, put the plastic into, and then on the top of the screw

- Q:How to remove the broken screw?

- The other are open to grow a little, grinding flat to seize the rotation, or the middle cut a knife with a zigzag tool to turn, the bigger the better to take the iron put on the surface of the welding, or with a word tool alignment loose Open the direction of the angle to play a few turn a few times, did not save the drill through the hole directly through the big mouth to re-open teeth on the line.

- Q:Why should the screw twist clockwise?

- Because the screw on the original flute is the clockwise direction of it

- Q:What is a self-tapping nail? Is it used? What are the characteristics of the shape? What is the difference with ordinary screws?

- Self-tapping screw head shape with round head, flat head, semi-countersunk head and countersunk head and so on. Materials generally carburized steel, heat treatment after the surface hardness of not less than 45HRC.

- Q:The mirror under the mirror put the toilet glass is broken, the original screw rust deformation, and pulled out. How to rust the screw

- That you can break before and after some of the expansion do not drip the oil or else you use the pliers light slippery when there is an empty time with a word screwdriver to feel almost when the pliers can be used

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Ball Lead Screw SFU1605

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Sets set

- Supply Capability:

- 1000 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords