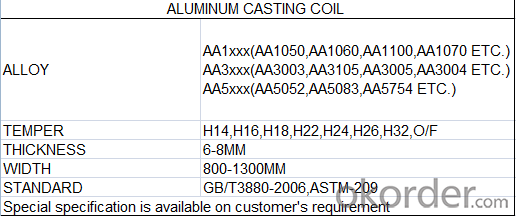

Aluminum Master Casting Coil 6-8mm in Alloys 1xxx, 3xxx,5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Master Casting Coil 6-8mm in Alloys:

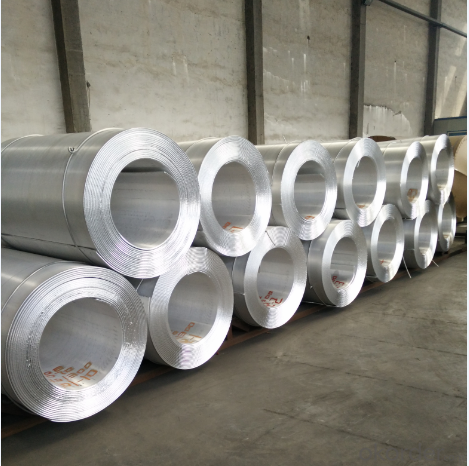

Aluminum Master Casting Coil 6-8mm in alloys is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of Aluminum Casting Coil for thin coil is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Aluminum Master Casting Coil 6-8mm in alloys:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Aluminum Master Casting Coil 6-8mm in Alloys

4. Production Process of Aluminum Master Casting Coil 6-8mm in Alloys

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Master Casting Coil 6-8mm in Alloys

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q:How do aluminum coils contribute to sustainable manufacturing practices?

- The numerous environmental and economic benefits of aluminum coils make them crucial for promoting sustainable manufacturing practices. To start, aluminum is an incredibly recyclable material, with almost 75% of all aluminum ever produced still in use today. This means that aluminum coils can be recycled and reused multiple times without losing their quality or performance. Unlike producing new aluminum, recycling aluminum requires only a fraction of the energy, resulting in significant energy savings and reduced greenhouse gas emissions. Furthermore, the lightweight nature of aluminum coils contributes to energy efficiency in transportation and reduces fuel consumption during shipping. This characteristic allows for more efficient use of resources, as less material is needed to achieve the same strength and durability compared to other metals. Consequently, this not only reduces the overall weight of products but also lowers the energy required for their fabrication and transportation. Moreover, the excellent corrosion resistance of aluminum coils extends their lifespan and reduces the need for frequent replacement. This factor not only saves resources but also reduces waste generation and associated environmental impacts. Additionally, aluminum coils are non-toxic and do not release harmful substances into the environment, making them a safe and sustainable choice for various manufacturing applications. In terms of economic benefits, aluminum coils contribute to sustainable manufacturing practices by offering cost savings throughout their lifecycle. The recyclability of aluminum reduces the need for raw material extraction, thereby lowering operational costs and dependence on virgin resources. Additionally, the lightweight nature of aluminum coils allows for more efficient use of energy and resources, resulting in reduced manufacturing and transportation costs. In conclusion, aluminum coils are essential for promoting sustainable manufacturing practices due to their recyclability, lightweight nature, corrosion resistance, non-toxicity, and cost-saving benefits. By integrating aluminum coils into manufacturing processes, companies can reduce their environmental footprint, conserve resources, promote energy efficiency, and contribute to a more sustainable and greener future.

- Q:Can aluminum coils be used in the production of aluminum curtain walls?

- Yes, aluminum coils can be used in the production of aluminum curtain walls. Aluminum coils are often used as a raw material for manufacturing curtain walls due to their lightweight, durability, and excellent corrosion resistance. These coils can be easily shaped, cut, and formed into the desired profiles, making them ideal for constructing curtain walls that are commonly used in modern architecture.

- Q:Are aluminum coils suitable for HVAC ductwork?

- Indeed, HVAC ductwork can be furnished with aluminum coils. The lightweight and corrosion-resistant attributes of aluminum coils render them the preferred choice for HVAC ductwork. These coils possess exceptional durability, enabling them to endure extreme temperatures and weather conditions. Additionally, aluminum coils exhibit remarkable thermal conductivity, facilitating efficient heat transfer and ensuring optimal cooling or heating efficacy. Furthermore, aluminum represents a non-toxic material, guaranteeing the safety of its employment in HVAC systems. All in all, aluminum coils serve as an ideal option for HVAC ductwork, furnishing enduring performance and energy efficiency.

- Q:1mm how much is one square meter for aluminum rolls?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet.

- Q:I would like to know because I'm getting a sword with an aluminum sheathe.

- Well, they make airplanes out of it so it's pretty strong. It has a good shearing strength. Now, over time, yes, you would wear the sheath with the steel blade, but I doubt you'll need to worry about it too much.

- Q:How are aluminum coils used in the production of furniture and fixtures?

- Aluminum coils are commonly used in the production of furniture and fixtures due to their lightweight and durable nature. They are mainly utilized for manufacturing furniture frames, legs, and other structural components. Additionally, these coils can be easily shaped and formed into various designs, allowing for versatility in furniture design. The use of aluminum coils also ensures resistance to corrosion, making the furniture suitable for indoor and outdoor settings.

- Q:Can aluminum coils be used for electrical transformers?

- Indeed, electrical transformers can utilize aluminum coils. The application of aluminum as a material for transformer coils is attributed to its superior electrical conductivity and cost-effectiveness in comparison to copper. Traditionally, copper has been favored for transformer windings; nevertheless, the utilization of aluminum has gained traction in recent times due to its lighter weight and more affordable price. Additionally, aluminum coils offer advantages in terms of thermal conductivity, as they efficiently dissipate heat in contrast to copper. Nevertheless, it is crucial to take into account the specific demands and design considerations of the transformer, as the decision between aluminum and copper coils may hinge upon factors such as voltage, current, size, and insulation requirements.

- Q:What are the weight and thickness options for aluminum coils?

- The weight and thickness options for aluminum coils can vary depending on the specific needs and requirements of the project or application. Generally, aluminum coils can range in weight from a few hundred pounds to several thousand pounds, while the thickness can range from a few millimeters to a few inches. It is important to consult with a supplier or manufacturer to determine the appropriate weight and thickness options based on the intended use of the aluminum coils.

- Q:How do aluminum coils perform in high-pressure applications?

- Aluminum coils perform well in high-pressure applications due to their excellent strength-to-weight ratio and corrosion resistance. They are capable of withstanding high pressures without deformation or failure, making them a reliable choice for various industrial and HVAC systems.

- Q:Are aluminum coils suitable for low-maintenance roofing applications?

- Yes, aluminum coils are suitable for low-maintenance roofing applications. Aluminum is known for its durability, longevity, and resistance to corrosion, making it an ideal material for roofing. Aluminum coils are lightweight yet strong, providing excellent structural integrity to withstand various weather conditions. Additionally, aluminum is a low-maintenance material as it does not rust or require regular painting. This means that homeowners or building managers can save time and money on maintenance tasks such as repainting or replacing rusted parts. Overall, aluminum coils are an excellent choice for low-maintenance roofing applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Master Casting Coil 6-8mm in Alloys 1xxx, 3xxx,5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords