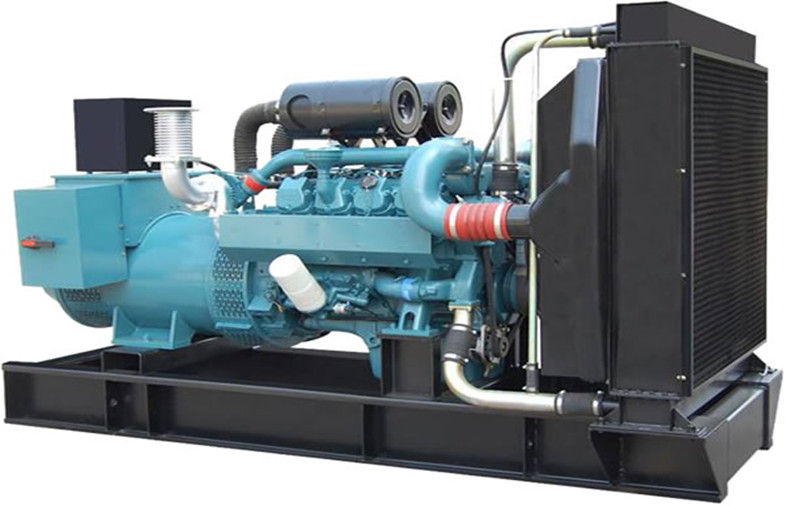

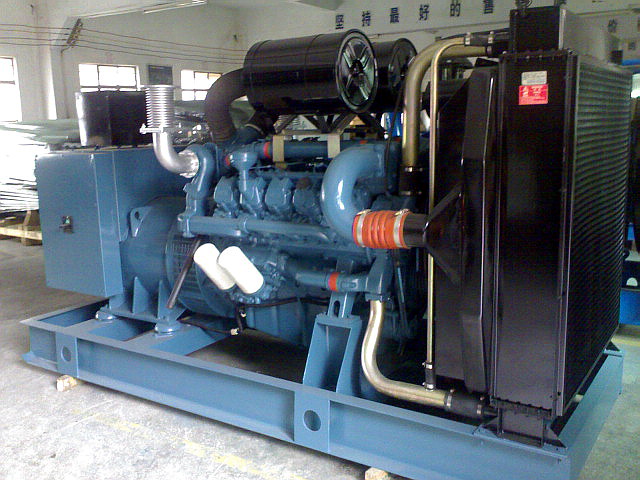

80kva - 600kva Doosan Power Genset Diesel Generator Standby

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

80kva to 625kva Standby Power Generator

1.Doosan Engine With Stamford Alternator

2.High Efficiency , Low Fuel Consumption

3.12 Months Warranty ,CE Approved

80kva - 600kva Doosan Power Genset Diesel Generator Standby

Specifications:

Genset Model | Prime Power | Standby Power | Engine | Fuel Consumption | Cylinder No. | Displacement | Bore X Stroke | ||

KW | KVA | KW | KVA | (g/kwh) | (L ) | (mm) | |||

GNR70DS | 50 | 62.5 | 55 | 70 | DB58 | ≤216 | 6 | 8 | 102*118 |

GNR94DS | 72 | 90 | 80 | 94 | D1146 | ≤216 | 6 | 8 | 111*139 |

GNR138DS | 100 | 125 | 110 | 138 | D1146T | ≤216 | 6 | 8 | 111*139 |

GNR200DS | 140 | 175 | 160 | 200 | D086TI-1 | ≤216 | 6 | 8 | 111*139 |

GNR225DS | 160 | 200 | 180 | 225 | P086TI | ≤216 | 6 | 8 | 111*139 |

GNR275DS | 200 | 250 | 220 | 275 | P126T1 | ≤216 | 8 | 8 | 123*155 |

GNR310DS | 220 | 275 | 250 | 310 | P126TI | ≤216 | 6 | 11 | 123*155 |

GNR350DS | 250 | 310 | 280 | 350 | P126T11 | ≤215 | 6L | 11 | 128*142 |

GNR413DS | 300 | 375 | 330 | 413 | P158LE-1 | ≤213 | V8 | 14.6 | 128*142 |

GNR450DS | 320 | 410 | 360 | 450 | P158LE | ≤212 | V8 | 14.6 | 128*142 |

GNR500DS | 360 | 450 | 400 | 500 | P158LE | ≤212 | V10 | 18.3 | 128*142 |

GNR550DS | 400 | 500 | 440 | 550 | P180LE | ≤212 | V10 | 18.3 | 128*142 |

GNR625DS | 450 | 560 | 500 | 625 | P222LE-I | ≤211 | V12 | 21.9 | 128*142 |

GNR700DS | 500 | 625 | 560 | 700 | P222LE-S | ≤211 | V12 | 21.9 | 128*142 |

Diesel engine:doosan engine

a) Multi-cylinder in-line or veer engine.4-stroke,direct injection

b) Governer Method:electrical or mechanical governor

c) Water cooling

d) Intake method:Natural apirated or turbocharged

e) Electric motor starting system

Alternator: Stamford,LeroySomer, Marathon,Engga

a) Brushless, 4 poles, rotation magnet

b) IP21-23(NEMA1) enclose is standard for all industrial alternators

c) H class insulation system

d) AVR self-regulated, voltage regulation rate: ≤±1%

e) Wide range of flange adaptors and single bearing disc coupling

f) Radio interference restraining accords with the stipulation of VDE0875-N and ISO8528

g) Moisture proof, sand-proof, dustproof, salt-proof and vibration-proof

Control plane :

a)Automatic alarm system: the unit has the acoustic-optics alarm system and arrestor for any situation as the start defeat, the water is over temperature the oil pulls down, over speed, over load and over current

b) Operation display:

i)Unit voltage, tri-phase load current and frequency display

ii)Water temperature, oil pressure display

iii)Fuel level, fuel temperature dieplay

iv)Audible and visual alarm lamps and buzzers

c)Emergency stop button

d)Three protection

Accessories

a) Standard accessories: Standard 40 radiator mounted on skid, Common steel frame, circuit breaker, damper, exhaust silencer, flexible pipe, battery and connecting wires, Standard tools kit, operation manual and document.

b) Optional accessories: Engine coolant and oil heater, alternator space heater, cooling for heat exchanger, communication interface, battery charger by main supply, daily fuel tank, ATS and paralleling system, soundproof canopy and moving trailer.

Warranty policy

Guarantee for one year or 1000 hours whichever reach first from ex-factory date. During the guarantee period, Genor will provide the free easy-damageable spare parts of diesel engine caused by our quality of production or raw material. After expiration, Genor provides cost spare parts maintenance of gensets.

- Q:What's the difference between an excited motor and an ordinary motor?

- Exciter and excitation generator is important equipment of power plants, it is produced by coaxial prime mover rotational dc, for excitation voltage to establish a magnetic field to the rotor of the generator

- Q:Why is electric motors not rotating? Everything else is good.

- Electric common failures and troubleshooting methods instrument display is normal, motor does not turn the cause of the problem: (1) brake the damage judgment (2) speed control to turn the damage judgment damage judgment, (4) (3) motor controller damaged troubleshooting: (1) remove the brake handle socket (normally open type brake handle). If the motor operates, the brake should be replaced. Turn the source 5V voltage to normal, check the signal voltage, turn the transfer, the signal voltage should be in 0.8 ~ 4.2 V from low to high. If the voltage is not changed and is less than 1V, then the fault or turn will be short-circuited. If the voltage is greater than 1V and the change is normal, the signal (yellow, green and blue) is detected. If the voltage of the three-phase hall signal line is 5V and is in good contact, the motor hall is damaged and the motor or motor hall elements should be replaced.

- Q:Can ordinary motors be matched with inverters?

- Ordinary motors can also be equipped with a frequency converter, and many of the older plants are now being upgraded with a frequency converter on the old motor.

- Q:The difference between servo motor and general motor?

- The problem of motor insulation strength is the small and medium frequency converter, many of which are controlled by PWM. He is about several thousand to more than 10 KHZ carrier frequency, which makes the motor stator winding to withstand high voltage build-up rate, equivalent to impose great impulse voltage gradient on motor, the motor of the turn-to-turn insulation withstand ordeal. In addition, the rectangular produced by PWM inverter chopper superposition of impulse voltage on the motor running voltage, would pose a threat to ground insulation of motor, the ground under the repeated impact of high voltage insulation can accelerate ageing. 3, harmonic electromagnetic noise and vibration Ordinary asynchronous motor by inverter power supply, can make the electromagnetic, mechanical, ventilation and other factors caused by the vibration and noise becomes more complicated. The internal harmonic interference of the different time harmonic and the electromagnetism of electromagnetism in the frequency conversion power supply, form various electromagnetic excitation forces. When the frequency of the electromagnetic wave is consistent or close to the natural vibration frequency of the motor body, the resonant phenomenon will be generated to increase the noise. Because the frequency of the motor is wide, the speed varies widely, and the frequency of all kinds of electromagnetic waves is difficult to avoid the natural vibration frequency of each component of the motor.

- Q:What's wrong with the rotary roller

- It's possible that the roller card is dead You turn the drum manually and look at the ready

- Q:Does the motor swing around?

- The rotation must be oscillating, and the motor will also produce the left and right swings of the left and right sides

- Q:What is the difference between the brake step motor and the step motor?

- Difference is the brake stepper motor is a kind of applied in special working environment of the motor For example, up and down movement of the table When braking power stepping motor will not move, while ordinary will continue to exercise, it is likely to hurt people or equipment

- Q:How do you differentiate the converter motor from the general motors?

- rter, the motor is the same, but the problem of controlling the frequency converter

- Q:Can you use a transducer to control the general motors? Recently, the factory has to renovate two 150 kw electric motors, which were previously controlled by the star delta, and now change the frequency converter, the electric motor is near the stove, the ambient temperature is higher. Please give me your opinion, thank you

- Ordinary motor can be controlled by frequency converter, don't make the motor work in low frequency zone, the electric motor works in low frequency area electric opportunity heat.

- Q:The difference between pump motor and general motor?

- Oil pump motor, also known as explosion-proof motor, is mainly used in coal mines, oil and gas, petrochemical and chemical industry. In addition, in textile, metallurgy, city gas, transportation, grain oil processing, paper, medicine and other departments are also widely used. The oil pump motor is used as the main power equipment, which is commonly used to drive pump, fan, compressor and transmission machine. And ordinary motors are not explosion-proof and can not be used in coal mines, oil and gas, petrochemical and chemical industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

80kva - 600kva Doosan Power Genset Diesel Generator Standby

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords