33117 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

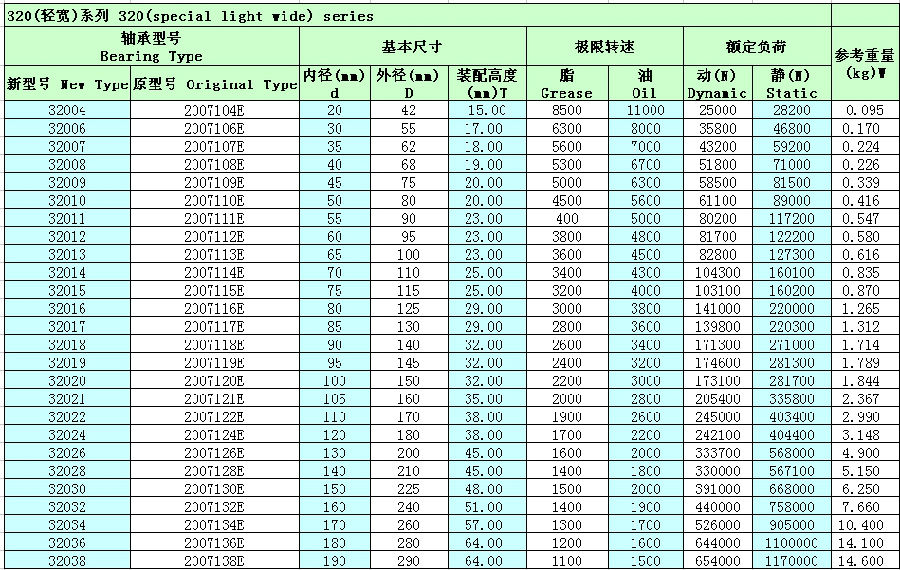

Specificatioin of Taperder Roller Bearings:

The tapered roller bearing is to bear the combination of radial and axial load but mainly afford radial load. The loading capibility is determined by the raceway angle of outer ring, the larger angle afford larger load. This kind of bearings can be seperated and it can be divided into single-row and double-row tapered roller bearings by the number of columns. The clearance for single-row tapered roller bearing should be adjusted by the customers when installation. For the double-row tapered roller bearings,the clearance has already set by the manufacture before ex-factory. Tapered roller bearing has taper shaped inner ring and outer ring raceway,and the roller elements arrange between them. All projection lines from the surface of rollers meet at the same point on bearing axis. This design makes tapered roller bearings particular suitable for combined (axial and radial) loads.The axial loading capacity is determined by the contacting angle α, the bigger angle for α, the larger axial loading capacity is. Tapered roller bearing is usually a seperated bearing, that is,the inner ring assembly including roller and cages, is seperated installed with the cup.

Taper roller bearings are mainly used for radial and axial joint load with radial load as main subject. Axial load capacity relies on raceway angle of outer ring: the bigger the angle is, the bigger the bearing capacity is. Outer ring can be separated and can be easily assembled. During installing and using process, axial clearance and radial clearance and radial clearance can be adjusted and pre-interference installation can be allowed.

Product application:

In many applications tapered roller bearings are used in back-to-back pairs so that axial forces can be supported equally in either direction.

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

- Q:What does "tapered roller bearing" suffix "A" mean?

- Tapered roller bearing suffix AA - angular contact ball bearings with a contact angle of 30 degreesA5 - angular contact ball bearings with a contact angle of 25 degrees

- Q:There are many kinds of tapered roller bearings, because of work requirements, test the external size is qualified, I want to make a test, to test the bearing is qualified, mainly inside and outside diameter and inside and outside the ring height tolerances, diameter ranging from 50mm--80mm, score less, look forward to your help, I thank you there are 322163311532215 main bearings, 313113002

- This is not easy yet. Do you think it's possible to make a standard check instrument yourself?!

- Q:you master good! Ask a question about the use of tapered roller bearings: a mechanism using a double row tapered roller bearings, but did not buy this model, can use two single row tapered roller bearing together instead of double row?

- Not so simple, please consider the following: 1, clearance of double row bearings generally have clearance design, and no single, you need to set in the middle of every lap, with good clearance, clearance or big or small, or no clearance, you miserable;

- Q:Turbine turbo rod reduction box, tapered roller bearing at both ends of wormGap measuring method, tapered roller bearingsThe gap is +-0.03, so how do I know the gap is in the range?.

- The utility model relates to a special measuring tool for the axial clearance of a tapered roller bearing, relating to a measuring tool used for measuring the gap between single row tapered roller bearings. Including about two relative PTFE gland set, the upper and lower ends of the gland in two PTFE is formed in the end of the notch, which formed a central notch, a notch in the center of the PTFE sleeve in the two or so is PTFE gland and PTFE sleeve are connected together by wing screw. The utility model has the advantages of greatly improving the measuring accuracy and accuracy, reducing the measuring error, and improving the maintenance efficiency and quality. It avoids the deviation in the maintenance process due to the different experience of the operator, and is simple and easy to operate.

- Q:Taper roller bearings limit speed, according to what to calculate, there is no formula for what?

- First of all, different types of tapered roller bearings, the limit speed is different. Bearing on catalog.Second, the calculation of bearing limit speed is calculated by computer simulation of bearing manufacturer. It is very complicated. Mainly based on frictional heat generation and cage strength limit.So, we use bearing technology or design personnel, only need to control your speed in the following catalog bearing manufacturers can.In addition, oil lubrication is better than grease lubrication at the same speed.

- Q:Online cylinder cones are GB/T4663, what do you mean?

- National standard GB 4663-1984, roller bearings, thrust cylindrical roller bearings, size, please check the mechanical design manual (Fifth Edition), second volumes --- commonly used rolling bearings, dimensions and performance parameters / thrust roller bearings.

- Q:Can tapered roller bearings be installed in a vertical direction? In a vertical direction rather than in a horizontal direction..

- Absolutely. The bearing below the figure is the tapered roller bearing placed vertically.

- Q:What are the general uses of tapered roller bearings?

- Widely used in machinery and equipment, water conservancy and Hydropower Engineering, railway, automobile, steel, textile, packaging, medicine, metallurgy, mining, petroleum, electric power, papermaking, computer, motor, sports equipment, office equipment, instrumentation, auto motor, precision instruments and other fields

- Q:Why is the cage of tapered roller bearings loose?

- It is loose, the outer frame of the bearing cone is removable, as long as it is easy to install and add lubricant.

- Q:What items should be inspected for tapered bearings?

- 1, the tapered roller bearing without cracks, sharp edges, plants and rust; on the road has not agreed to the raceway of machining trace; super fine traces in the outer ring, the steel ball surface should be symmetrical task differences, not to have scratches, bumps;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

33117 Tapered Roller Bearigs Single Row Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords